Dicing & Back Grinding Tape

LINQTAPE Dicing and Backgrinding tapes are tapes specifically designed to be used in semiconductor and electronics manufacturing processes. These tapes feature a strong adhesive system designed for secure wafer handling during critical processes such as dicing and thinning. By utilizing high-performance materials with advanced adhesive properties, the tapes enhance both process efficiency and wafer yield, all while reducing the risk of damage during cutting and grinding operations.

The dicing and backgrinding tapes are engineered to be tough, offering superior adhesion during wafer processing while utilizing UV Removable technology. This allows them to remain easily removable without leaving residue or compromising the wafer’s integrity. Unlike traditional alternatives, these tapes maintain their reliability and performance even under the stress of high-speed cutting and grinding, offering enhanced service life and reducing operational costs. They are ideal for sensitive applications and substrates such as glass, electronics, etc.

DCT-PET115 | Polyethylene Die Cutting Tape

- 115 µm film thickness

- Acrylic adhesive

- Specifically tailored for glass and ceramic

- 8 weeks

DCT-PO165 | Polyolefin Die Cutting Tape

- 165 µm film thickness

- UV removable acrylic adhesive

- Gentle adhesion for packaging substrates and glass

- 8 weeks

DCT-PO200 | Polyolefin Dicing Tape

- 200 µm film thickness

- UV removable acrylic adhesive

- Gentle adhesion for packaging substrates and glass

- 8 weeks

DCT-PVC95 | Polymerized Vinyl Chloride Dicing Tape

- 95 µm film thickness

- UV removable acrylic adhesive

- Strong adhesion for silicon wafer applications

- 8 weeks

DCT-PVC80NUV | Polymerized Vinyl Chloride Dicing Tape

- 80 µm film thickness

- Translucent Film

- Acrylic non UV adhesive

- 8 weeks

BGT-PO130 | Polyolefin Back Grinding Tape

- 130 µm film thickness

- UV Removable acrylic adhesive

- Back grinding compatible, general purpose

- 8 weeks

BGT-PO180 | Polyolefin Back Grinding Tape

- 180 µm film thickness

- Urethane UV removable adhesive

- High accuracy and easy to peel

- 8 weeks

Product Selector Guide

Dicing Tapes

| Product | Description | UV Removable | Film Thickness (um) | Adhesive Thickness (um) | Total Thickness (um) | Adhesion Strength (Before UV) | Adhesion Strength (After UV) | Elongation (Lengthwise/Crosswise) | Tensile Strength (Lengthwise/Crosswise) |

|---|---|---|---|---|---|---|---|---|---|

| DCT-PET115 | Polyethylene Film with Acrylic Adhesive | Yes | 100 | 15 | 115 | 19,000 | 100 | - | - |

| DCT-PO165 | Polyolefine Film with Acrylic Adhesive | Yes | 150 | 15 | 165 | 18,600 | 180 | 941 / 838 | 34 / 31 |

| DCT-PO200 | Polyolefine Film with Acrylic Adhesive | Yes | 150 | 50 | 200 | 23,000 | 200 | 903 / 867 | 34 / 31 |

| DCT-PVC95 | Polymerized Vinyl Chloride Film with Acrylic Adhesive | Yes | 80 | 15 | 95 | 3,200 | 140 | 320 / 340 | 31 / 25 |

| DCT-PVC80NUV | Polymerized Vinyl Chloride Film with Acrylic Adhesive | No | 70 | 10 | 80 | 1,601 | - | 271 / 324 | 27 / 20 |

Back Grinding Tapes

| Product | Description | UV Removable | Film Thickness (um) | Adhesive Thickness (um) | Total Thickness (um) | Adhesion Strength Before UV (mN/25mm) | Adhesion Strength After UV (mN/25mm) | Elongation % (Lengthwise/Crosswise) | Tensile Strength (N/25mm) (Lengthwise/Crosswise) |

|---|---|---|---|---|---|---|---|---|---|

| BGT-PO130 | Polyolefine Film with Acrylic Adhesive | No | 100 | 30 | 130 | 1,200 | - | 650 / 800 | 24 / 20 |

| BGT-PO180 | Polyolefice Film with Acrylic Adhesive | Yes | 150 | 30 | 180 | 18,000 | 80 | 830 / 740 | 34 / 30 |

Frequently Asked Questions

Frequently Asked Questions About Dicing tapes & Grinding tapes

How are dicing/backgrinding tapes applied?

Dicing tapes are applied to the backside of the wafer, while backgrinding tapes are applied to the frontside of the wafer. The first step is to ensure the wafer is clean, by removing any contaminants. Then the tape is applied to the desired side. Any airbubbles are smoothed out, and the excess is cut off.

Learn More

What is the Dicing Process?

In Semiconductor manufacturing, one of the most critical steps is the dicing of the wafer. During the dicing process, a high-speed saw (or laser) cuts through the wafer, cutting it into smaller pieces called dies.

Why are Dicing Tapes Required?

Dicing tapes are specialized tapes designed for use during the above process. They are thin, flexible, and have a strong adhesion layer. The tape's main purpose is to support the wafer. By providing a supportive backbone, the tape allows for cleaner cuts. It holds the wafer securely, which means the delicate wafer won't break during the cutting process. Another important advantage of using dicing tapes is that the tape is designed to be removed easily, allowing the individual dies to remain intact and free of any residue.

.png)

How are Dicing Tapes used in the Dicing Process?

The wafer is first cleaned from any dust or particles, then placed on the sticky side of the dicing tape. Any excess around the wafer is cut off to have a seamless edge.

What are the Advantages of Dicing Tapes?

Some advantages of using tapes in the dicing process include:

- Thermal stability - the high-speed cutting can generate heat, which means the tape must withstand high temperatures.

- UV Removable - the tapes can be easily removed by applying UV light to the tape

- Strong adhesion - the strong adhesion of the dicing tape provides security during the cutting process by keeping the wafer in place.

.png)

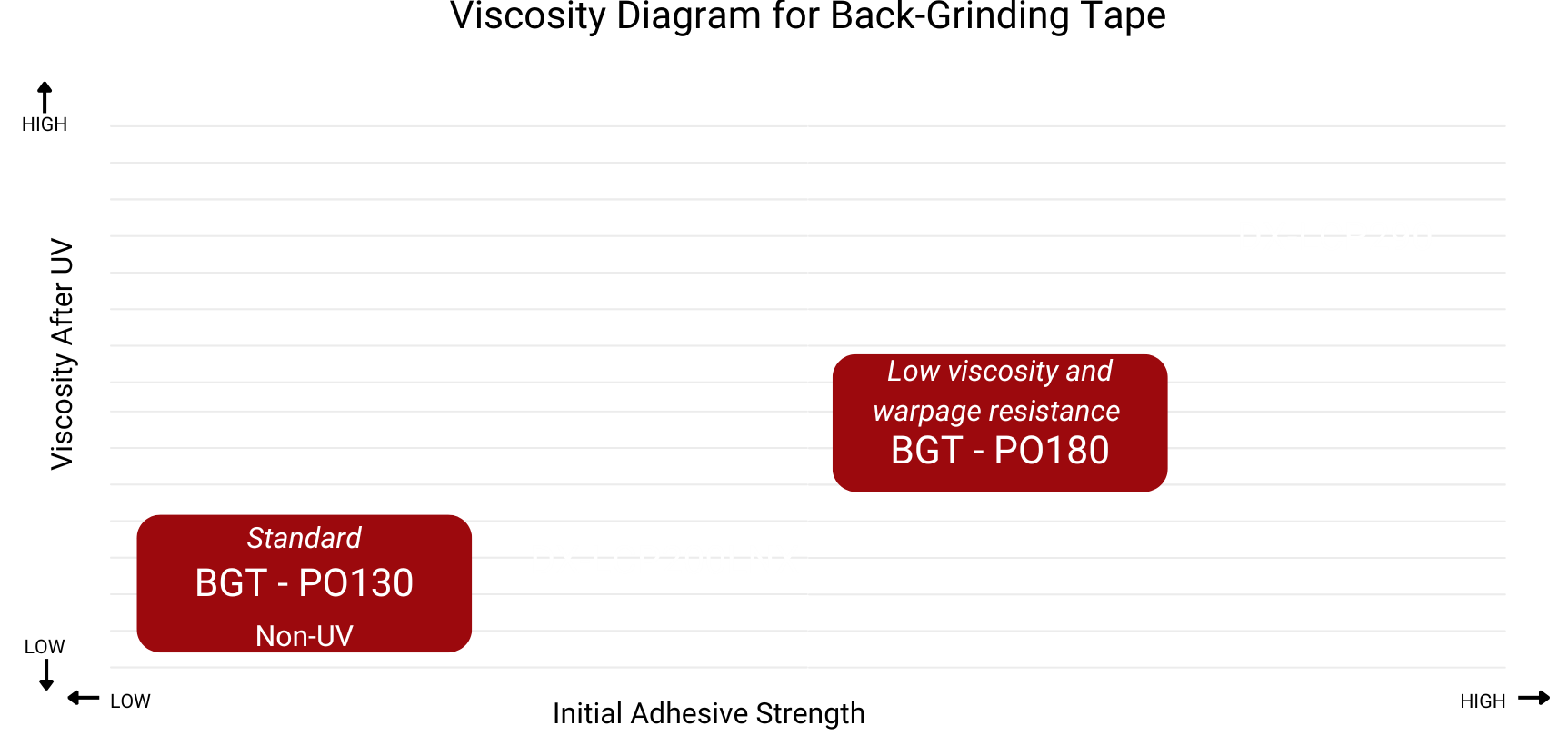

Figure 1. Viscosity Diagram for Caplinq Dicing Tapes

What is UV Removable Dicing Tape?

Some Dicing tapes have UV Removable technology. When UV Light is applied, the adhesive becomes less tacky and allows for easy removal. This works because of the adhesive. The adhesive used is sensitive to UV light, and when exposed to it it chemically alters to lose its bonding strength. One of the most important qualities of this technology is that no residue is leftover on the substrate. This makes it ideal for wafers and can be used on other sensitive substrates such as optical glass.

What is the Backgrinding Process?

The backgrinding process is another critical process in semiconductor manufacturing. Before the wafer is cut into dies, the thickness needs to be correct. Since wafers are usually initially processed thicker than required, the backgrinding process is used to grind it down. In this process, the back part of the wafer is ground using a highly abrasive material, often made of diamond. This is usually a grinding wheel and has different abrasive levels.

How are Backgrinding Tapes used in the Backgrinding Process?

During the backgrinding process, tape is used the secure the wafer during grinding. This prevents movement during the process, which will allow the wafer to remain secure and not move. Another advantage of using tape during the backgrinding process is protecting the components of the delicate front side of the wafer. The front side of the wafer contains the active layers which require protection. The tape is applied to the front side, and then the wafer is applied to a holder before the grinding process begins. Once the grinding of the wafer is complete, the tape is removed from the wafer, and the wafer is sent over for the next processing steps, which include dicing. The tape must be able to peel off easily as to not damage the wafer. Another requirement is that the tape must not leave any residue, which will interfere with subsequent steps if left on.

What's the Difference between a Dicing Tape and a Backgrinding Tape?

The main difference between the two tapes is the application and placement. A dicing tape is placed on the backside of the wafer, while the backgrinding tape is placed on the front of the wafer.

What are the Key Features of Backgrinding Tapes?

Some advantages of backgrinding tapes include:

- High adherence - the strong adhesion of the tape helps to keep the wafer secure, and also prevents soaking (prevents contaminants from adhering to the front side of the wafer where the tape is placed).

- Heat resistance - like dicing tapes, grinding during the backgrinding process can generate heat. The tape must be able to withstand high temperatures

- UV removable - backgrinding tapes can easily be removed using UV light, leaving the wafer clean without adhesive residue.

.png)

Figure 2. Viscosity Diagram for Caplinq Backgrinding Tapes