Magnet fixing

Magnet fixing refers to the method of attaching magnets to the rotor or stator of an electric motor. This is a critical step in the motor manufacturing process as it determines the stability and reliability of the motor. There are several different ways to fix magnets in place, including:

Adhesive bonding: This involves using an epoxy or other type of adhesive to attach the magnets to the rotor or stator. This method is popular because it is relatively simple and inexpensive.

Press-fitting: In this method, the magnets are placed in a machined groove in the rotor or stator and then pressed into place using a hydraulic press. This method provides a more secure hold, but can be more challenging to implement.

Welding: In some cases, the magnets can be welded directly to the rotor or stator. This method provides a very strong hold but requires specialized equipment and expertise.

It's important to choose the right method for fixing the magnets, depending on the specific requirements of the motor and application. Factors to consider include the strength and stability of the magnet attachment, the operating conditions of the motor, and the manufacturing process.

Fixation of Magnets in Rotors using Epoxy Molding Compounds

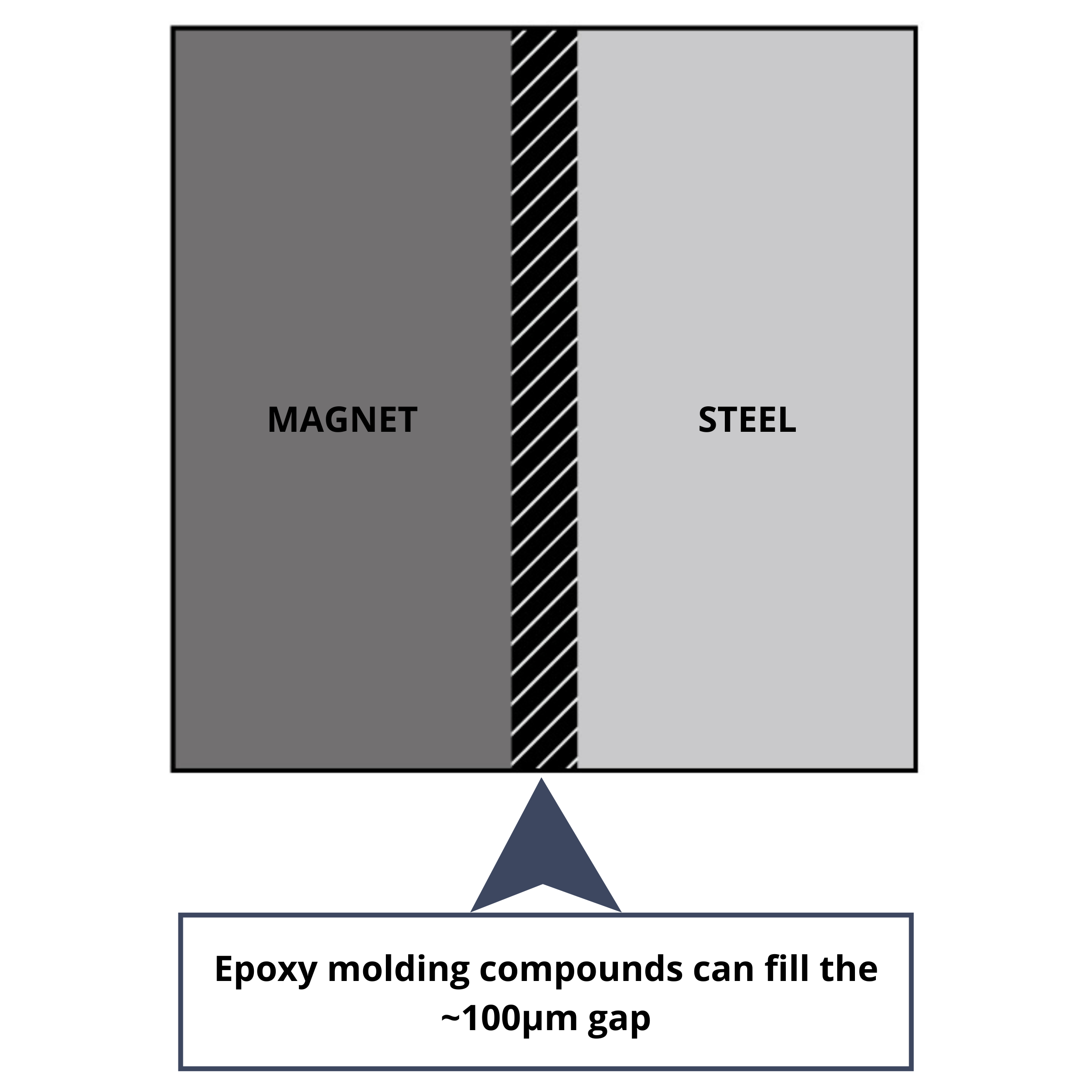

While we are active in the resin fixing field we also suggest other options that are similar to that, namely epoxy molding encapsulant. The fixation of the permanent magnet in the rotor steel through non-screw injection molding and transfer molding has successfully used thermosetting epoxy molding compounds. EMC is melted and pressed into the gaps and then it solidifies, keeping the magnets in place. Unlike liquid encapsulants, epoxy molding compounds offers faster cycle time and great corrosion resistance.

Narrow-Gap Filling Epoxy Molding Compounds

Molding compounds have already been used in Rotors with Iron as a base material and with rotor working speeds up to 20000 rpm and working temperatures up to ±150°C. There are rpoxy molding compounds that can pass both Temperature cycling and High-temperature ATF resistance tests while retaining 100% of their flexural strength and flexural modulus. This highlights the product's excellent property stability post post-automotive fluid resistance testing.

HysolEM LMC-565U-G is the perfect solution for protecting and securing your electric motor's magnets. This black, rotor magnet encapsulant is being used in the automotive, eMobility industry as an alternative to traditional resin fixing techniques. It claims a very low CTE, High Tg, and good and reliable encapsulation. It has 70% filler content and is based on OCN/MAR chemistry with a PN hardener.

Hysol GR30 is a halogen-free, black, semiconductor-grade epoxy molding compound or duroplast designed for the encapsulation and protection of TO220 and TO247 power devices. GR30 was successfully used to bond the magnet and rotor core using a transfer molding method. This product is an environmentally "Green" product, meaning that it doesn't contain any bromine, antimony or phosphorus flame retardants. HysolGR30 product is excellent in competing with the Sumitomo M500 TypeA.

EMC for Magnet Fixing Product Properties Comparison

| PROPERTY | UNIT | M500 Type A | GR30 | LMC-565U-G |

| Specific Gravity | - | 1.87 | 1.94 | 1.85 |

| Spiral Flow @175°C | cm | 75 | 66 | 139 |

| Hot Plate Gel Time @175°C | sec | 20 | 19 | 14 |

| Glass Transition Temperature | °C | 170 | 178 | 174 |

CTE by TMA, α1 CTE by TMA, α2 | ppm ppm | 15 55 | 15 54 | 18 60.5 |

Thermal Conductivity | W/m·K | 0.8 | 1.0 | 0.65 |

Flexural Strength @25°C Flexural Modulus @25°C | MPa Gpa | 170 17 | 110 15.6 | 130 13.6 |

| Mold Shrinkage | % | 0.39 | 0.24 | 0.4 |

| Flame Retardancy | UL-94 | V-0 | V-0 | V-0 |

| Shelf Life and Storage Condition | mon | 9 months below 5°C | 9 months below 5°C | - |

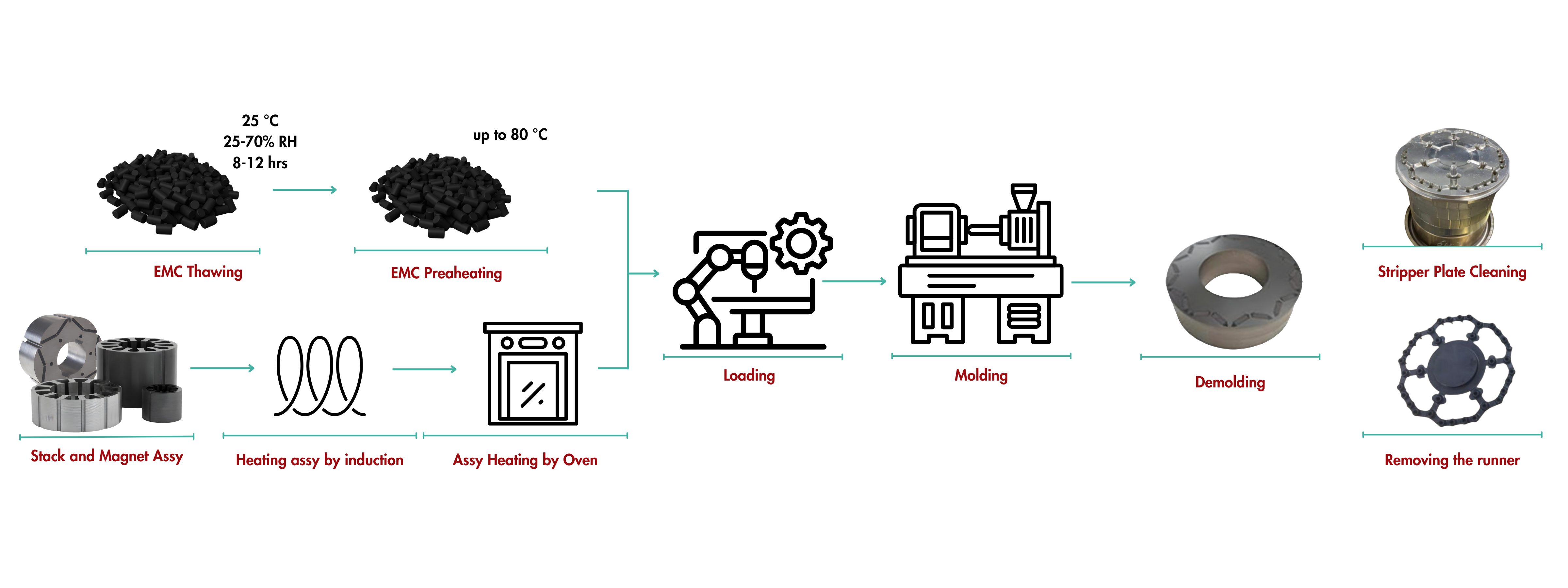

Magnet Fixing Through EMC Molding Process Flow Chart

| Step No | Process | Device | Description |

1 | Thawing of Epoxy Molding Compound | - | Thawing of Epoxy molding compound pellets at room temperature (25°C) and 25-70 % RH for about 8-12 hours. |

| 2 | Preheating of Epoxy Molding Compound | Microwave Heater | Pre-heating of EMC pellets from 25°C to 80°C for 25-30 seconds before molding |

| 3 | Heating the component by Induction | Induction Heating Device | Heating the components of the rotor including the magnets by induction. The rate of heating should not be faster than 1°C/second to prevent yellowing of the rotor stack. |

| 4 | Heating the component by Oven | Oven | Heating the components by oven to achieve uniform temperature distribution of 175°C. |

| 5 | Loading | Robot | Loading of the EMCs and and component to the molding equipment |

| 6 | Molding | Molding Equipment | 1. Locking the mold. Mold Pressure should be arounf 3-20 tons (6720-44800 psi) 2. Injecting the EMC, transfer pressure should be about 0.7-1T (1500-2200 psi) 3. Hold the mold pressure and temperature for about 2 minutes at 175°C. |

| 7 | Demolding | Robot | 1. Transferring of the molded stack to next station 2. Removing the runner. 3. Cleaning and visual checking of stripper plate while keeping the temeperature of the stripper plate at 175°C. before next cycle. |

There are several slots that go through the core. The permanent magnets are inserted in the slot and then the mold compound is filled into the gap to bind the magnet and the rotor core together.

The critical function of the material is to have a strong binding force between the magnet and the rotor core while also having a good filling capability. It should also have excellent reliability at working temperature. GR30 is a green material without Br/Sb, in compliance with ROHS that can cure fast for high Units per Hour.

Effect of Molding Temperature on Rotor Magnets Demagnetization

In producing motor rotors during injection molding magnets that are being used are either magnetic or non-magnetic. Fixing the magnets through injection molding requires all of the components to be pre-heated preheated and exposed to around 175 degC molding temperature. Depending on the grade of the magnetic magnet being used we expect a certain degree of demagnetization.

To avoid temperature-induced demagnetization, the use of non-magnetic magnets during injection molding is employed and post-integral magnetization after rotor assembly is adopted to magnetize the magnets.

Other types of magnets such as Ferrite-based and cobalt-based and AlNiCo materials have higher resistance to demagnetization due to their higher maximum operating temperature and relativity high thermal stability.