Thermal Interface Materials

Thermal Interface Materials, often abbreviated and TIM materials, are used to dissipate heat as quickly and effectively as possible from the device. But not all devices are the same. Requirements are driven by product use, product life cycle, packaging design, and operating conditions. Smartphones and tablets experience sudden temperature spikes, requiring very high thermal performance, while power electronics in automobiles need extreme thermal stability to meet warranties that stretch over long lifetimes.

That’s why our products optimize thermal impedance. This means that we look at the entire thermal path, not just the thermal interface material itself. This includes the material interfaces, the thermal expansion of the joining interfaces, contact resistance and bond line thicknesses.Moreover, all products are technically reworkable, some easier than others. Our portfolio of materials is designed to dissipate heat away from the IC, in an appropriate way for the device structure, packaging design and application.

The design of Honeywell’s portfolio of phase change materials (PCMs) is driven by an innovative polymer technology and advanced filler system, which can be customized to fit diverse product applications and end uses.In addition to our phase change materials, we offer a variety of products with high thermal conductivity and high compressibility, including thermal gap pads, Thermal Hybrid, thermal grease, thermal insulators, and more. Are you working with optical switches, high Gs and need pluggable thermal interface materials? We are already developing and qualifing variable pluggable TIMS. Contact us for more information.

Frequently Asked Questions

Can I have a quick Overview of all your Thermal interface materials?

The following table serves as a "single glance" Product selector guide for our entire Thermal interface material catalogue. Each entry links you to the category or the product itself where you can find extensive and useful information and the full product specifications along with the available Technical and Safety Datasheets.

| APPLICATION | CATEGORIES | PRODUCTS | KEY FEATURES | THERMAL CONDUCTIVITY (W/m·K) |

|---|---|---|---|---|

| High Reliability Thin Bondline | Phase Change Materials | LTM6300-SP | Paste Only | 1.8-2.4 |

| PCM45F-SP | High Reliability | 2.0-2.5 | ||

| PTM5000 | High Reliability | 3.5-4.5 | ||

| PTM5000-SP | Stencil printable | 3.5-4.5 | ||

| PTM6000 | High Reliability | 3.5-4.5 | ||

| PTM6000HV | High Viscosity, IGBT printing | 5.2 | ||

| PTM7000 | Low TI, High Reliability, Pad form | 6.5 | ||

| PTM7000-SP | Stencil printable | 6.5 | ||

| PTM7000-SPS | Stencil printable with Slow drying time | 6.5 | ||

| PTM7900 | Balanced solution, Pad form | 8.0 | ||

| PTM7900-SP | Stencil printable | 8.0 | ||

| PTM7950 | High end Phase change, Pad form | 8.5 | ||

| PTM7950-SPS | Stencil print, Slow drying time | 8.5 | ||

| High Compressibility Gap Filler | Thermal Gap Pads | TGP1200 | Cost Effectiveness | 1.2 |

| TGP1500 | Cost Effectiveness | 1.5 | ||

| TGP3000 | Low Hardness | 3 | ||

| TGP5000 | Low Hardness | 5 | ||

| TGP6000 | Low Oil Bleeding | 6 | ||

| TGP8000 | Low Oil Bleeding, Low Outgassing, Low Hardness | 8 | ||

| TGP8000HV | High Breakdown Voltage | 8 | ||

| Thermal Putty Pads | TGP3500PT | Extra Soft | 3.5 | |

| TGP6000PT | Extra Soft | 6 | ||

| TGP8000PT | Extra Soft | 8 | ||

| Thermal Conductivity Electrical Isolation | Thermal Insulators | TIP1500 | High Breakdown Voltage | 1.5 |

| TIP3500 | High Breakdown Voltage | 3.5 | ||

| Ease of Application Ultra-Thin Bondline ( | Thermal Grease | TG2000I | Cost Effectiveness, Electrical Isolation | 2 |

| TG2800I | Cost Effectiveness, Electrical Isolation | 2.8 | ||

| TG3000 | Cost Effectiveness | 3 | ||

| TG3000I | Cost Effectiveness, Electrical Isolation | 3 | ||

| TG4000 | High TC, Low TI | 4 | ||

| TG5500 | High TC, Low TI | 5.5 | ||

| Automation Gap Filler | One-Part Hybrid | HT3500 | Cost Effectiveness | 3.5 |

| HT4500 | Printable, Thermally stable | 4.5 | ||

| HT5010 | Pre-cure, Low Oil Bleeding | 5 | ||

| HT7000 | Pre-cure, Low Oil Bleeding | 7 | ||

| HT9000 | Pre-cure, Low Oil Bleeding | 9 | ||

| HT10000 | Pre-cure, Low Oil Bleeding | 10 | ||

| Automation Gap Filler | Two-Part Hybrid | HLT2000 | Cost Effectiveness | 2 |

| HLT2000LV | Low Volatility | 2 | ||

| HLT3000 | Stencil print, No moisture absorption | 3 | ||

| HLT3500 | Cost Effectiveness | 3.5 | ||

| HLT7000 | High Reliability, Easy to Dispense | 7 | ||

| HLT10000 | High Reliability, Easy to Dispense | 10 |

Learn More

Thermal interface materials

Introduction

The modern electronics industry is constantly advancing toward higher power consumption and more integrated functions and miniaturization, resulting in a sharp increase in the power density of modern electronic devices. In fact, we have entered the era of 5G.

Therefore, efficient heat dissipation has become an even more critical requirement for the design of modern electronic packages. Thermal interface materials (TIMs) are widely employed to manufacture the most critical parts in the heat dissipation system, to cool and protect integrated circuit (IC) chips.

Honeywell TIMs are based on proprietary technologies of polymer matrices and thermally conductive fillers, enabling them to handle challenging heat dissipation issues with long-term reliability and low cost of ownership.

Thermal Performance

Product Life Cycle & Reliability

Mobile products such as tablets and smartphones have a relatively short product life, but still require thermal management to protect from extreme and sudden bursts of energy and temperature spikes. Conversely, automotive, power and server products must remain robust for significantly longer product life cycles.

These applications involve harsh operating conditions such as extreme heat and humidity, which must be taken into account in choosing the best TIM material. The key requirement in these applications is not just immediate performance but also sustained, long-term thermal stability

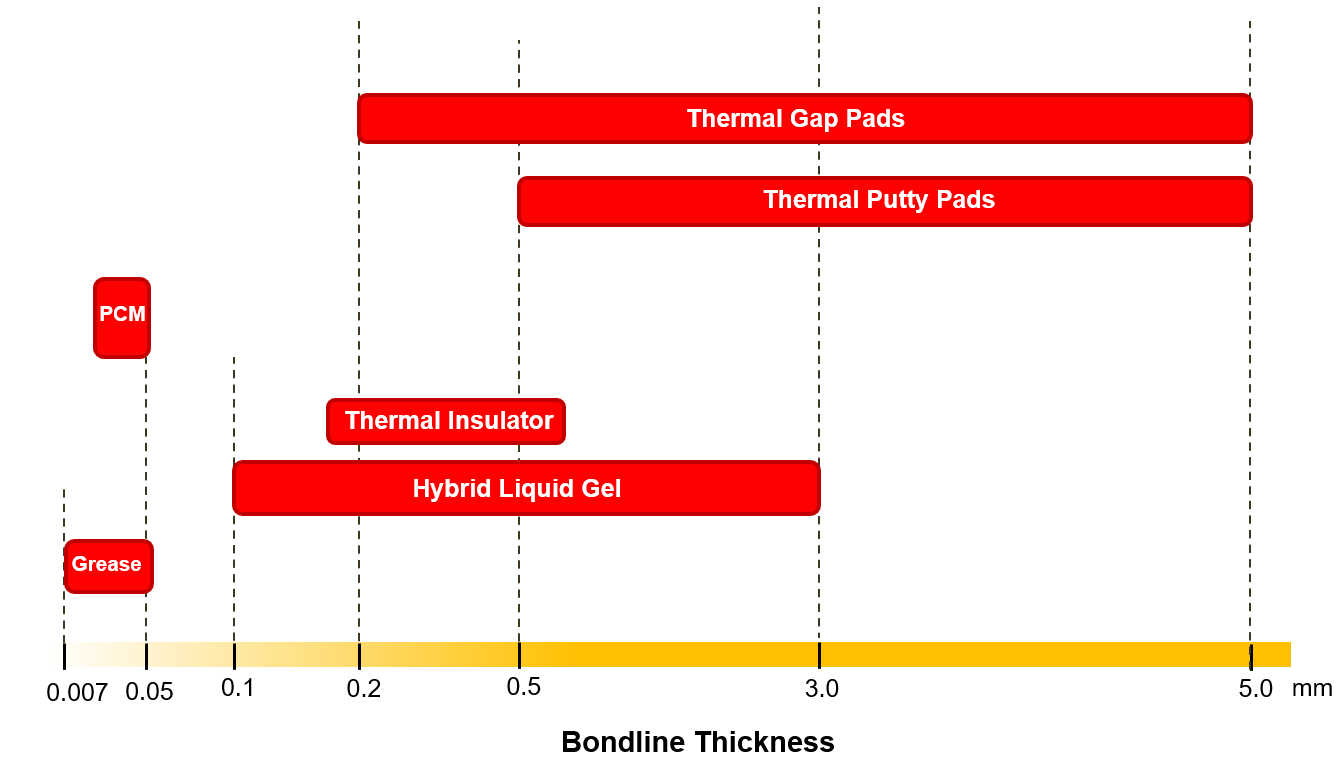

Gaps & Bondline Thickness

Thermal Management Solution Fundamentals

Product Selection Guide

Having a hard time deciding where you should start? Use this handy decision-making steps to select the properties that are most important to your application.

.png) | .png) | .png) | .png) | .png) |

1. Applications

What are the most proven applications? You could quickly find the most common application scenarios of each TIM, which means they are widely applied in those industries.

2. Bondline Thickness

Dimensions matter a lot! The space between the component and heat sink is very small, from microns to millimeters. Honeywell TIMs provide various materials with different bondline thickness for your applications.

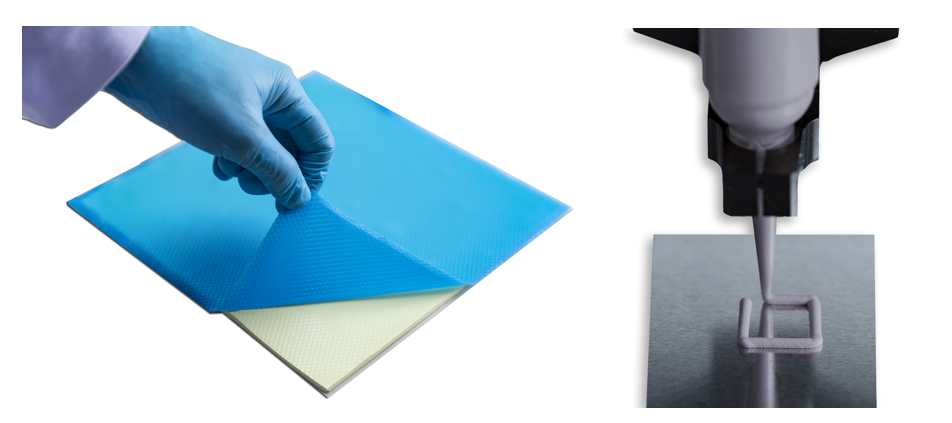

3. Will the TIM be applied automatically or manually?

Do you want to automatically apply your TIMs, including stencil printing and dispensing? The liquid version TIMs are a good choice in this case, such as phase change material SP version, hybrid and thermal grease.

4. Thermal Performance

5. Reliability and Other Features

| Key Features | Thin Bond Line Materials (0.07mm~0.1mm) | Gap Filler Materials (0.1mm~5mm) | ||||

|---|---|---|---|---|---|---|

| Phase Change Materials | Thermal Greases | Thermal Gap Pads | Thermal Putty Pads | One-part Hybrid | Two-Part Hybrid | |

| Silicone-Free | ✓ | ✗ | ✗ | ✗ | ✗ | ✗ |

| Reliability | Excellent | Medium | Excellent | Excellent | Medium | Excellent |

| Comformability | Excellent | Excellent | Medium | Excellent | Excellent | Excellent |

| Printable/Dispensable | ✓ | ✓ | ✗ | ✗ | ✓ | ✓ |

| Single Process | ✗ | ✓ | ✓ | ✓ | ✓ | ✗ |

| Temperature Range | <125°C | <200°C | <200°C | <200°C | <200°C | <200°C |

| Pros |

|

|

|

|

|

|

| Cons |

|

|

|

|

|

|

Thermal Interface Material Design Advantages & Disadvantages

| Property | Advantages | Disadvantages |

| Adhesion | Adhering to surface prevents air encroachment | Transfer of CTE stresses Cure cycle |

| Increased Viscosity | Material doesn't flow out of the gap | Bond line increase More pressure needed |

| Viscoelastic Properties | Tune to resist flow | Difficult with resin volume |

| Increased melting point | Forms solid outer ring to prevent flow | High temperature burn-in Self healin reduced |

| Cure in place | No flow | Delamination potential 2k, 1K issues |

TIMs Characterization & Testing

View Thermal Interface Materials Applications

.png)

.png)

.png)

.png)