Antistatic Tapes

LINQtape Polyimide Tapes include a series of Anti-Static Tapes and films with an anti-static polymer coating on top of the polyimide layer. These anti-static tapes have a surface resistance of 1x1012 ohms per square.

LINQtape ESD products are high-temperature resistant, antistatic treated polyimide films coated with acrylic or silicone adhesive. They are designed for both masking and temporary bonding in many high temperature applications found in semiconductor, electronic, automotive and other general manufacturing industries.

Our antistatic product line up provides an excellent balance of electrical, mechanical, thermal, and chemical properties over a wide range of temperatures. It has enhanced strength for puncture and tear resistance and can be used in applications that may see high intermittent temperatures.

PIT1A-ESD | 1mil Antistatic ESD Polyimide (Kapton) Tape with Acrylic Adhesive

- 1 mil polyimide film

- Acrylic adhesive

- >6000V breakdown voltage

- 2 weeks

PIT1A-ESD-B | 1 mil Black XC ESD Conductive Polyimide (Kapton) Tape with Acrylic Adhesive

- 1 mil polyimide film

- Acrylic adhesive

- >6500V breakdown voltage

- No longer available

PIT1A-ESD-BRL | 1 mil Black Conductive ESD Tape with Acrylic Adhesive & Release liner

- 1 mil polyimide film

- Acrylic adhesive with release liner

- >6500V breakdown voltage

- 2 weeks

PIT1S-ESD | 1-mil Antistatic ESD Polyimide (Kapton) Tape with Silicone Adhesive

- 1 mil polyimide film

- Silicone adhesive

- >6,500V breakdown voltage

- 2 weeks

PIT1S-ESD-DCD | 1 mil Die Cut ESD Polyimide (Kapton) Tape with Silicone Adhesive | Single side Discs

- 1 mil polyimide film

- Single side Silicone adhesive

- >6500V breakdown voltage

- 2 weeks

Product Selector Guide

| Product name | Description | Adhesive type | Adhesive thickness | Polyimide thickness | Total thickness | Peel Strength (oz/in) | Breakdown Voltage (V) |

|---|---|---|---|---|---|---|---|

| PIT1A-ESD | 1mil Antistatic ESD Polyimide (Kapton) Tape with Acrylic Adhesive | Acrylic | 1.5mil (38µm) | 1mil (25.4µm) | ±2.5mil (63.5µm) | 25 | 6,000 |

| PIT1S-ESD | 1-mil Antistatic ESD Polyimide (Kapton) Tape with Silicone Adhesive | Silicone | 1.5mil (38µm) | 1mil (25.4µm) | ±2.5mil (63.5µm) | 25 | 6,500 |

| PIT1A-ESD-BRL | 1 mil Black Conductive ESD Tape with Acrylic Adhesive & Release Liner | Acrylic | 1.5mil (38µm) | 1mil (25.4µm) | ±2.5mil (63.5µm) | 25 | 6,500 |

| PIT1S-ESD-DCD | 1 mil Die Cut ESD Polyimide (Kapton) Tape with Silicone Adhesive | Single Side Discs | Silicone | 1.5mil (38µm) | 1mil (25.4µm) | ±2.5mil (63.5µm) | 25 | 6,500 |

Frequently Asked Questions

What is the difference between polyimide and Kapton?

DuPont were the original inventors of polyimide tape in the 1960\'s. They patented their product as Kapton tape. The patent for Kapton expired a long time ago, and the generic name version of the product is polyimide. DuPont continue to supply their Kapton tape under their brand name at a premium, but in reality, the material properties are exactly the same as polyimide.

Can I order a polyimide tape or film in a width other than what you have on your website?

Yes. Polyimide tapes and films are cut to width based on customer requests. For tapes the thinnest width we can reliably cut in 3mm (1/8 inch) wide, for film this is 6.5mm (1/4 inch) and for both tape and film the widest is the jumbo roll width of 508mm (20 inch). Otherwise, please ask us for any specific width you need. Minimum order quantities may apply.

What is the difference in operating temperature range for the different kinds of polyimide tape?

The operating temperature range of our polyimide films is between -269°C (-452°F) and 260°C (500°F). For the different types of tape this range is limited because of the specifications of the adhesive used. Our polyimide tapes with silicone adhesive have an operating temperature range between -73°C (-100°F) and 260°C (500°F). Our polyimide tapes with acrylic adhesive have an operating temperature range between -30°C (-22°F) and 175°C (347°F).

How can I apply your pressure sensitive tapes?

All our adhesives used for our polyimide tapes are pressure sensitive adhesives (PSA). This means they form a bond between two surfaces solely by surface contact, which is achieved by light external pressure to the adhesive or surfaces. PSA\'s are dry adhesives that can be applied at room temperature and require no activation with water, solvent or heat. Another advantage is that they adhere instantly saving time in production processes.

How can I remove pressure sensitive adhesive residue?

This will be completely application dependant. Since the adhesives are pressure sensitive, it will depend on the pressure you\'ll apply, the duration before peeling and of course the temperature and the type and smoothness of the surface. Hence it is almost impossible to say anything about the existence (or not) of residue.

IF there is residue, there are various ways to get rid of it with either heat (softening), cold (embrittlement), or chemical removal but we cannot recommend anything that might damage the rest of the package. As a rule of thumb, pressure sensitive adhesives do not harden to a cohesively strong solid. They are viscous liquids, and remain so when incorporated in an adhesive joint, so softening will (probably) be the easiest way.

Can I order a polyimide tape or film in a thickness other than what you have on your website?

Yes. Most of our polyimide tapes and films are available in a range of standard thicknesses; 12.7 micron (0.5 mil), 25.4 micron (1 mil), 50.8 micron (2 mil), 38.1 micron (3 mil), 127 micron (5 mil) and 254 micron (10 mil). The thinnest we can manufacture is 12.7 micron (1/2 mil) thick, thickest is 254 micron (10 mil) thick. Otherwise, please ask us for any specific thickness you need. Minimum order quantities may apply.

Learn More

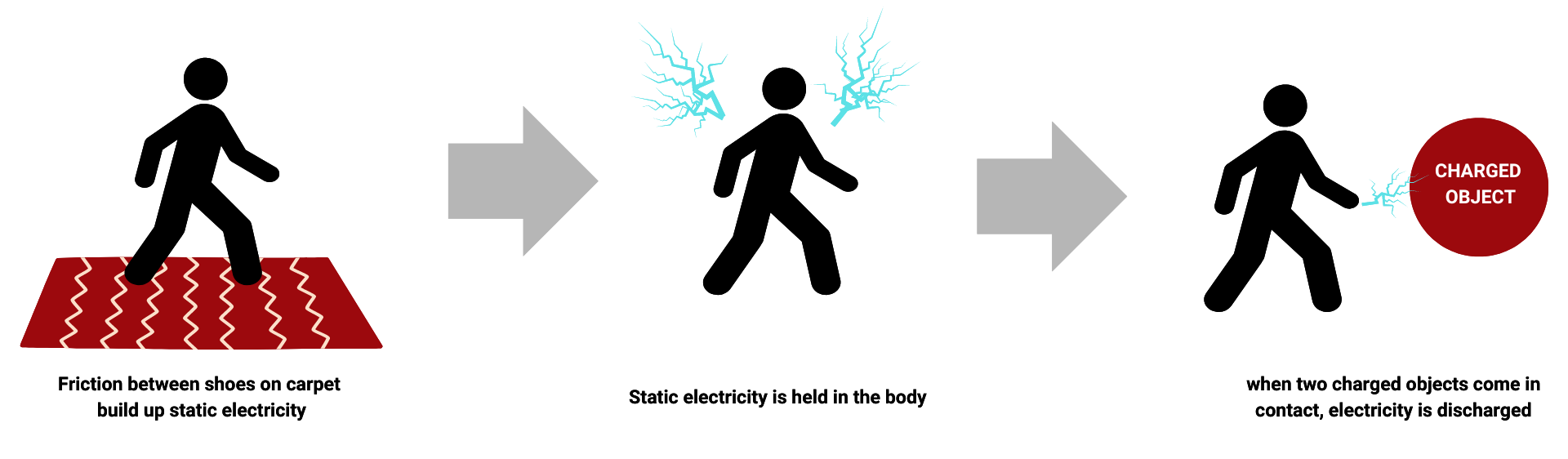

What does ESD mean?

ESD stands for Electrostatic Discharge. Electrostatic discharge occurs when two charged parts come into contact with each other. It can also occur due to an electrical short or dielectric breakdown. ESD causes damage to electrical components that leads to malfunctioning or even permanent damage. The most common example is when one walks on a carpet, then a small shock occurs after touching another person or conductive object. This happens due to the friction between the shoes and the carpet, which generates static electricity. When the person comes in contact with the other "charged part", the energy is discharged.

Antistatic Tapes Applications

ESD is an issue for many industries and applications, especially those containing sensitive electronic components. Not taking the correct precautions for ESD is a safety, quality, and production concern. Some industries that benefit from the use of ESD tapes are:

- Electronics manufacturing (PCBs, used during assembly to protect sensitive components)

- Semiconductor industry (wafer handling, die attachment)

- Automotive industry (used during assembly to protect sensitive components)

- Medical industry (sensitive components)

- Consumer electronics (phones, tv's, tablets)

ESD Prevention with Antistatic Tapes

Antistatic tapes work by creating a pathway for electricity to be discharged. This prevents the buildup of electricity and gives it a conduit to pass through to dissipate. The tapes are made out of materials that dissipate or neutralize static electricity. Antistatic tapes are not only created to prevent ESD. They have multiple advantageous properties, including high and low temperature resistance, high puncture resistance, and high tear resistance.

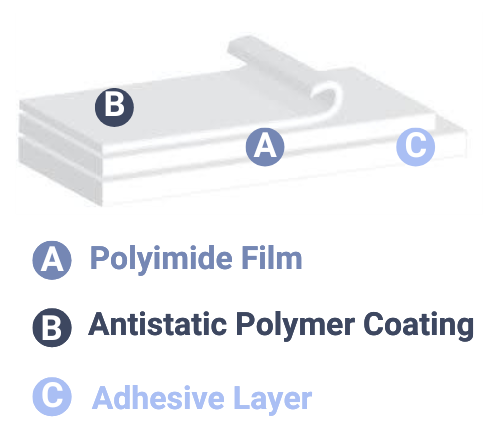

Product Cross Section

Antistatic tapes are made up of 3 components. First, you have the polyimide film, second, you have the antistatic polymer, and lastly you have the adhesive layer. The adhesive layer can be composed of acrylic or silicone. In some cases, a release liner is also required. This doesn't affect the chemistry or final thickness of the tape.