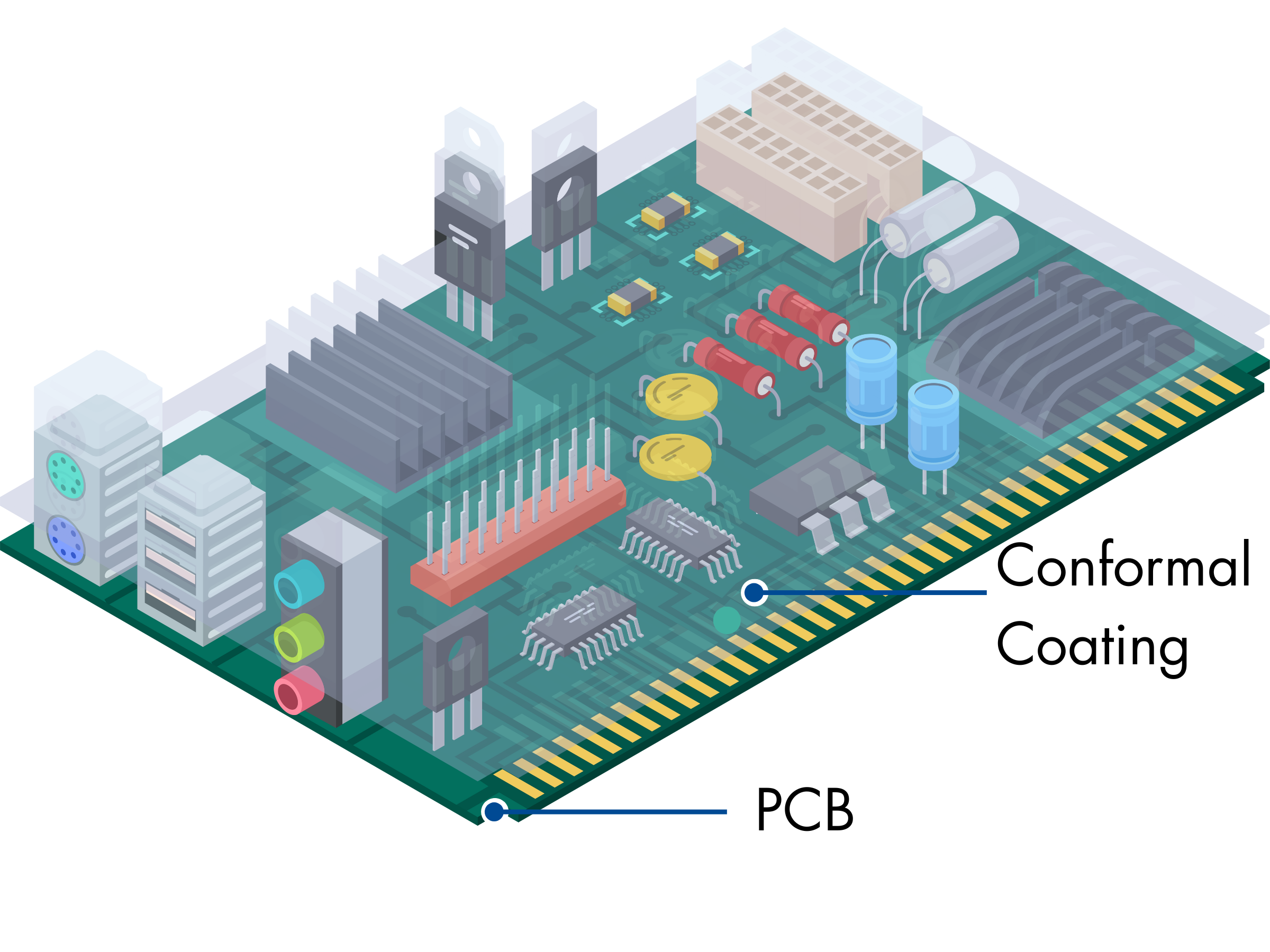

Conformal Coatings

A conformal coating is a thin, protective polymer film applied over electronic assemblies to defend against moisture, chemicals, dust, and other environmental hazards. What makes it “conformal” is its unique ability to follow the exact contours and geometries of complex PCBs and components, forming a seamless, invisible barrier without altering the design or function of the assembly.

Conformal coatings extend the functional life of electronics by preventing corrosion, contamination, and short circuits. They also contribute to product ruggedness, reduce field failure rates, and help manufacturers meet extended warranty commitments and regulatory reliability standards.

Conformal Coatings Available at CAPLINQ

CAPLINQ offers a wide range of conformal coatings based on different chemistries, including acrylics, silicones, synthetic rubbers, and UV-curable acrylates. Each chemistry offers distinct properties suited for specific application requirements, such as electrical insulation, moisture resistance, chemical protection, or mechanical flexibility.

These coatings are also available with varied curing mechanisms (e.g. moisture, heat, UV), allowing compatibility with different production speeds and process constraints.

For application-specific recommendations or technical support, feel free to get in touch. Contact us →

Humiseal 1B73 | Acrylic conformal coating

- Acrylic Conformal Coating

- Transparent (UV Fluorescent)

- Dielectric Strength - 6300 V

- 8 weeks

Humiseal 1A33 | Urethane Conformal Coating

- Urethane Conformal Coating

- Transparent (UV Fluorescent)

- Low moisture vapor permeability

- 6 weeks

Humiseal UV40 | Acrylated Urethane Conformal Coating

- Acrylated Urethane Conformal Coating

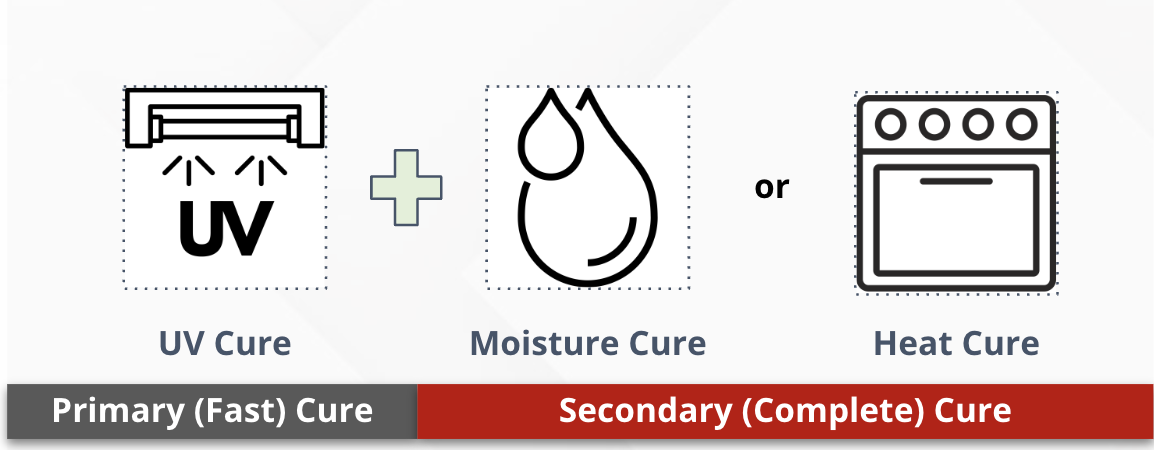

- Secondary cure mechanism cures any unexposed areas

- Excellent chemical and moisture resistance

- 8 weeks

Humiseal UV40 LED | LED UV Curable Conformal Coating

- Tack free cure with LED UV light

- Excellent chemical and moisture resistance

- Dual-cure mechanism

- 8 weeks

Humiseal 1A20 | Fast-Curing Polyurethane Conformal Coating

- Fast-curing

- Fluoresces under UV light

- Flexible and repairable

- 12 weeks

Humiseal UV92 | Urethane acrylate UV masking material

- Easily Applied by syringes, dispensing machines

- Keeps contact points and connections free of coating

- Easily removed by peeling - leaves no residue to interfere with subsequent operations

- 12 weeks

Humiseal 2C51 | Silicone Conformal Coating

- Fast Room-Temperature Cure

- Excellent Electrical Insulation

- Visual Quality Control with UV Tracer

- 12 weeks

Humiseal 2A64 | Urethane Conformal Coating

- Exceptional Electrical Insulation

- Easy Quality Control

- High environmental resistance

- 12 weeks

Humiseal 1B51NSLU | Synthetic Rubber Conformal Coating

- Fast-drying

- Low moisture vapor permeability

- Environmentally friendly

- 8 weeks

Humiseal 1B58LU-60 | Toluene-Free Synthetic Rubber Conformal Coating

- Toluene-free

- Improved thermal stability

- Low moisture vapor permeability

- 8 weeks

Humiseal 1A20R | Polyurethane Conformal Coating

- One-component

- Fast-curing

- Chemically-resistant

- 12 weeks

Humiseal 1A27 | Polyurethane Conformal Coating

- One-component

- Fast-curing

- No free isocyanates

- 8 weeks

Humiseal 1A27LU | Urethane Conformal Coating

- Isocyanate-free

- Single-component

- UV fluorescent

- 8 weeks

Humiseal 1A33 GEL | Thixotropic Polyurethane Paste

- Thixotropic Gel Consistency

- Solvent-Free and No Free Isocyanates

- UV Fluorescence for Inspection

- 8 weeks

Humiseal 1A68 | Urethane Conformal Coating

- No Free Isocyanates

- UV Fluorescence

- Polyurethane Chemistry

- 8 weeks

Humiseal 1B15 | Fast-Drying Acrylic Conformal Coating

- One-component

- Superior flexibility and abrasion resistance

- MIL-I-46058C, Type AR Compliant

- 8 weeks

Humiseal 1B51 | Synthetic Rubber Conformal Coating

- One-component

- Superior flexibility and abrasion resistance

- MIL-I-46058C Compliant

- 12 weeks

Humiseal 1B51LU | Fast-Drying Synthetic Rubber Conformal Coating

- Fast-drying formula

- Low moisture vapor permeability

- RoHS Directive 2002/95/EC Compliant

- 8 weeks

Humiseal 1B51NS | One-Component Synthetic Rubber Conformal Coating

- Fast-drying formula

- Low moisture vapor permeability

- Flexible & low stress

- 12 weeks

Humiseal 1C49LV | Low-Viscosity Silicone Conformal Coating

- VOC-free

- Fluoresces under UV light

- Compatible for use in aerospace applications

- 12 weeks

Humiseal 1C51 | Low-Viscosity, Fast Thermal Curing Silicone Conformal Coating

- VOC-free

- Fast thermal curing

- Fluoresces under UV light

- 12 weeks

Humiseal 1C53 | Low-Viscosity, Fast Thermal Curing Silicone Conformal Coating

- VOC-free

- Fast thermal curing

- Fluoresces under UV light

- 12 weeks

Product Selector Guide

| Product | Type | Appearance | Film Thickness (μm) | Cure Type | Glass Transition Temperature Tg (℃) | Viscosity (mPa·s) | Dielectric Strength (kV/mm) | Dielectric Constant / Dissipation Factor at 100 kHz | Volume Resistivity (Ω·cm) |

|---|---|---|---|---|---|---|---|---|---|

| Humiseal 1A33 | Polyurethane | - | Varies | RT (30 days) or 88℃ (20h) | 54 | 180 | - | 3.6/0.03 at 1 MHz | - |

| Humiseal 1B73 | Acrylic | - | Varies | RT (24h) or 76℃ (2h) | 42 | 250 | - | 2.6/0.01 at 1 MHz | - |

Frequently Asked Questions

Frequently Asked Questions about Conformal Coatings

How is a conformal coating applied?

There are multiple ways to apply a conformal coating, all based on the specifics of the application. Some common methods include:

- Hand Brushing

- Hand Dispensing

- Spray Coating (Aerosol or Handspray)

- Dip Coating

- Selective Coating

How does conformal coating work?

The liquid coating “conforms” to every contour of the assembly, creating a continuous protective film that shields components from moisture, dust, chemicals, and electrical leakage.

How do I choose the right conformal coating chemistry?

Selection depends on environmental stresses, thermal range, humidity, mechanical stress, chemical exposure, and reworkability needs. For example:

- Acrylics – easy to apply and rework, limited high-temp resistance

- Silicones – excel in high-humidity, high-temp, vibration-heavy environments

- Polyurethanes – resist solvents and abrasion

- UV-curable – ideal for high-speed, inline production

Can conformal coatings be applied selectively?

Yes. Automated selective coating equipment can precisely deposit coating only on critical areas—leaving connectors, test points, or sockets exposed—reducing masking and cleanup.

Learn More

Conformal Coatings

Thin polymeric films applied to electronic circuits and components to protect them from environmental conditions, such as:

- Moisture and humidity

- Dust and chemicals

- Corrosive atmospheres (e.g., salt spray)

- Temperature extremes

They “conform” to the shape of the board and its components — hence the name — forming a protective barrier without affecting the function of the electronics.

Protecting Electronics Across Industries

Conformal coatings are essential in industries where electronic reliability is critical under environmental stress. From automotive to aerospace, consumer tech to medical equipment, these coatings form a thin, invisible shield that protects sensitive circuitry from moisture, dust, chemicals, and thermal extremes, enhancing performance, safety, and service life.

Consumer Electronics

Smartphones, wearables, home devices

Automotive

ECUs, sensors, lighting modules

Industrial

Control systems, IoT nodes

Aerospace & Defense

Avionics, guidance systems

Conformal Coating Product Ecosystem

The effectiveness of a conformal coating system relies not only on the coating itself but also on the complementary products that ensure precise application, consistent performance, and easy rework. A typical ecosystem includes:

Conformal Coating

- Uniform, thin protective barrier

- Prevents moisture, dust, corrosion

Chemistries:

- Acrylics

- Silicones

- Urethanes

- UV-curable

Thinner

- Adjusts spray, dip or brush viscosity

- Ensures uniform film thickness

Selection:

- Match solvent blends to each chemistry

- Balance thinning vs. adhesion

Stripper

- Removes cured coatings safely

- No damage to sensitive components

Types:

- Fast-acting solvents for bulk

- Gentle spot-stripping formulas

Masking Materials

- Protects connectors & test points

- Leaves critical areas coating-free

Options:

- Liquid masks

- Peelable tapes

- Silicone plugs

Types of Conformal Coatings According to Chemistry of Base Resin

Conformal coatings come in several chemistries, each offering unique protective properties and application characteristics suited for different environments and industry needs. The most common types include acrylic, silicone, polyurethane, epoxy, and parylene coatings. These materials vary in terms of moisture resistance, chemical durability, flexibility, ease of application, and reworkability, making the selection dependent on the specific performance demands of the application.

Acrylic

Pros: Easy to apply and remove; dries quickly and is cost-effective for general use.

Cons: Limited chemical and temperature resistance; not ideal for harsh or high-performance environments.

Urethane

Pros: Strong resistance to moisture, chemicals, and abrasion; good for automotive or industrial use.

Cons: Rigid and harder to rework; long curing times and possible outgassing issues.

Silicone

Pros: Excellent flexibility and thermal stability; ideal for high-temperature or outdoor use.

Cons: Difficult to remove or rework; may have limited chemical resistance depending on formulation.

Rubber

Pros: Cost-effective coating with balanced performance for less demanding environments.

Cons: Limited high-temperature resistance; moderate chemical resistance.

Conformal Coating Selector Guide based on Resin Chemistry

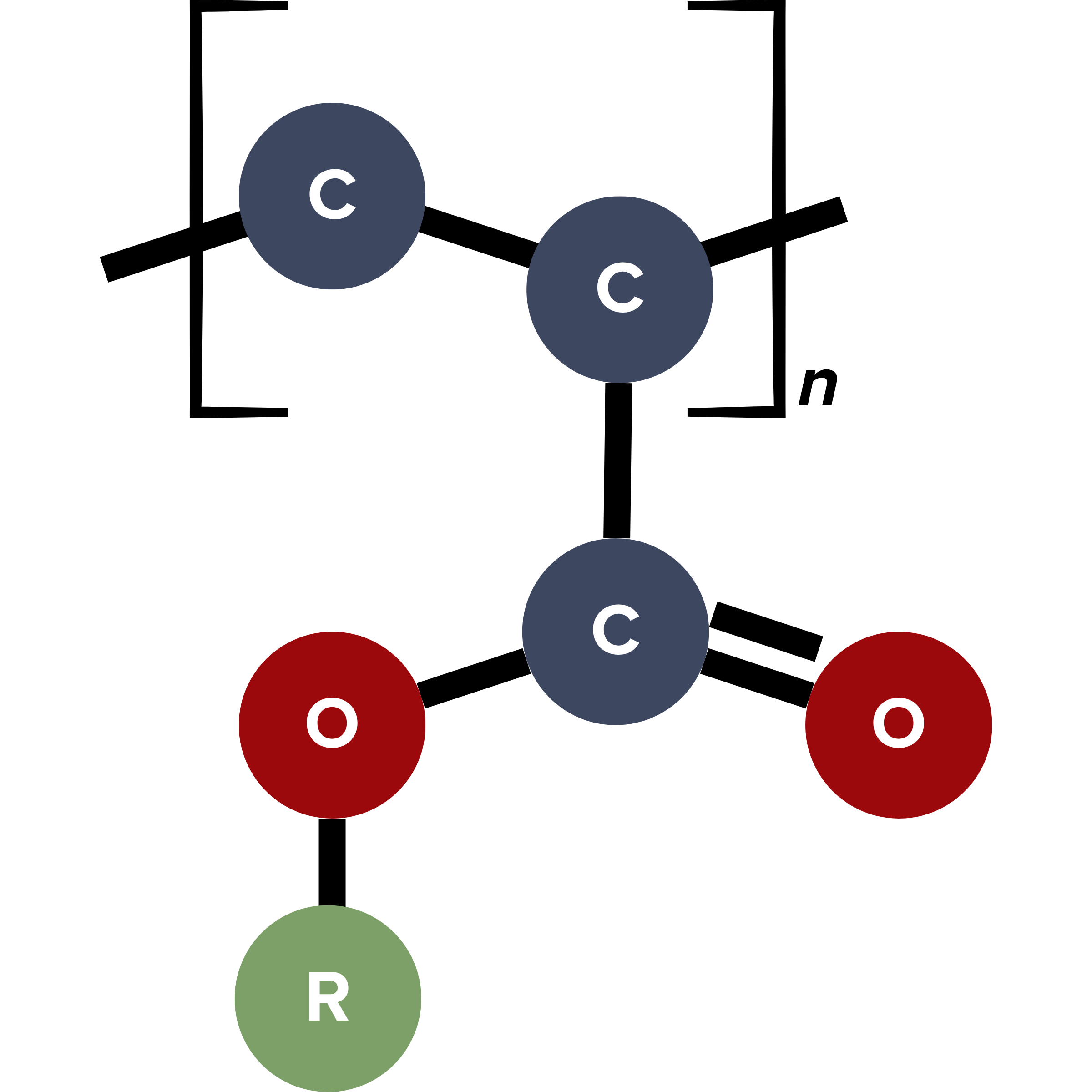

Acrylic conformal coatings are typically based on polymers derived from acrylic acid or methacrylic acid esters. These resins are linear and thermoplastic, which means they do not crosslink during curing. This gives them high reworkability and allows for fast curing.

Acrylic-based coatings represent the largest market share of conformal coatings. The widespread choice of acrylics can be attributed to their ease of use, short cure time, and reworkability/repairability.

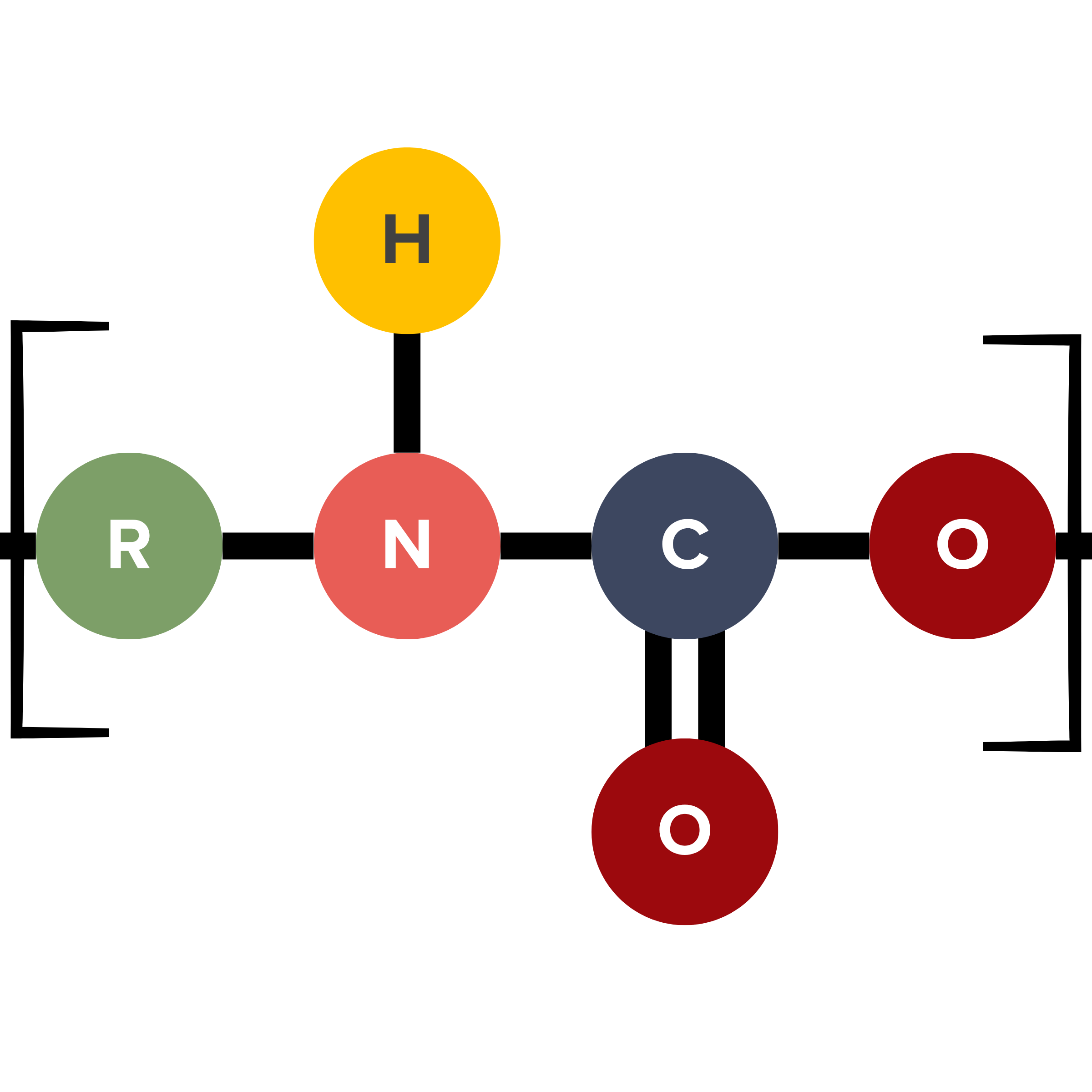

Polyurethane coatings are formed by crosslinking polyols with isocyanates, resulting in a flexible, tough layer with excellent abrasion and chemical resistance. Compared to acrylics, polyurethanes offer higher chemical resistance and mechanical strength, second only to epoxies. However, they remain easier to rework than epoxies and stand up well to salt spray and industrial gases. Note that polyurethane coatings typically require longer curing times.

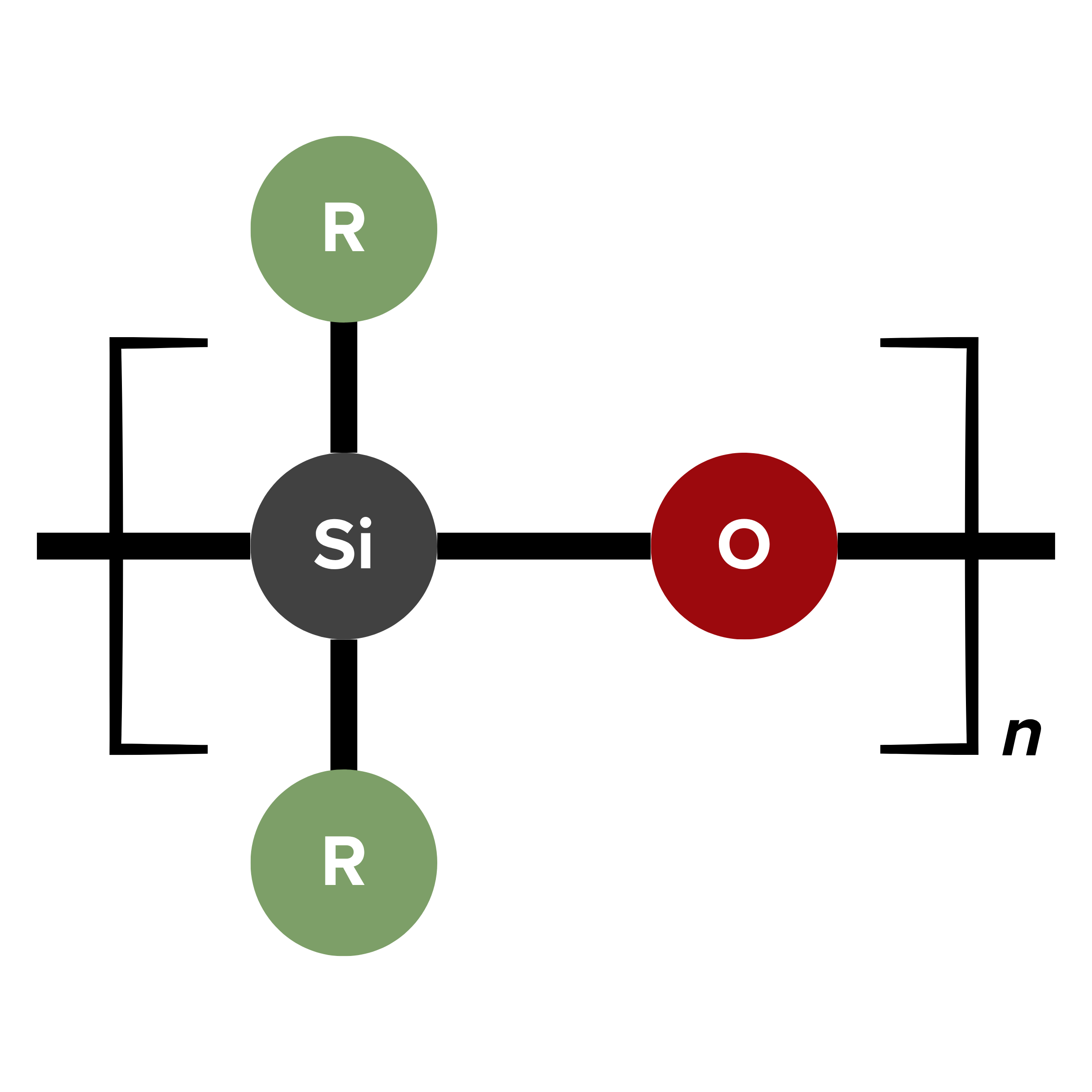

Silicone-based conformal coatings are uniquely characterized by their exceptional high-temperature performance. The strong, thermally stable Si–O bonds in silicones outperform the carbon–carbon bonds found in acrylics, enabling these coatings to withstand temperatures above 150 °C. They excel in applications like industrial mining equipment, high-temperature electronics, and underhood automotive components.

While silicones are not as abrasion-resistant due to their rubbery flexibility, this same property allows them to absorb vibration. Removal typically requires specialized solvents, prolonged soak times, and mechanical agitation.

Synthetic rubber conformal coatings are elastomer-based films, often made from butyl rubber or styrene block copolymers. They offer moderate reworkability and good moisture resistance. Though not as chemically or thermally robust as polyurethanes or silicones, they deliver balanced performance for less demanding environments and withstand vibration and damping stresses well.

★★★★☆

★★☆☆☆

★★☆☆☆

★★☆☆☆

★★★★☆

$

★★☆☆☆

★★★★☆

★★★★★

★★★☆☆

★★★★☆

$$

★★☆☆☆

★★★★★

★★★☆☆

★★★★★

★★★★★

$$$

★★☆☆☆

★★★★☆

★★★☆☆

★★★☆☆

★★★☆☆

$

★★☆☆☆

★★☆☆☆

★★★★☆

★★★☆☆

★★★★☆

$$

Types of Conformal Coatings According to Curing Mechanisms

Solvent Evaporation

Film cures as dissolved resin solids deposit when the solvent (or water) flashes off at room temperature or with mild heat.

Acrylics

Synthetic Rubbers

Moisture Cure

One-part formulations that crosslink when ambient moisture diffuses into the film and triggers polycondensation or addition.

Silicones

Polyurethanes

Heat Cure

Requires elevated temperature (often 80–150 °C) to drive crosslinking reactions in the absence of UV or moisture.

Two-part Epoxies

2K Polyurethanes

UV Cure

Uses photoinitiators that, upon UV absorption, generate radicals or cations to rapidly polymerize acrylate-based resins.

Multifunctional Acrylates

Epoxy-modified Acrylates

Dual Cure

Combines two mechanisms (e.g., UV + moisture, UV + thermal) to ensure cure in shaded areas or to boost final properties.

Hybrid Chemistries

(e.g., Acrylate + Silicone)

UV-curable Conformal Coatings

UV-curable conformal coatings are thin polymeric films applied to electronic assemblies that rapidly crosslinks and solidifies when exposed to ultraviolet (UV) light. This technology addresses the length cure cycles and complications on solvent handling required in early conformal coatings. UV-curable coatings are typically multifunctional acrylates or epoxy-modified acrylates that provide hardness and chemical resistance.

Another processing advantage is that this technology is environmentally friendly, as it contains no volatile organic compounds (VOCs) or solvents. Like silicone coatings, it is 100% solid. Due to the short cure time, UV-curable conformal coatings are suitable for high-volume applications.

Key Features

- UV cure in seconds

- Eliminates bake/flash steps

- High chemical resistance; moderate moisture barrier

- Tough yet flexible; abrasion-resistant

- 100 % solids; zero VOC/solvent

- Compact UV stations (no ovens)

- Optimized for high-volume inline lines

- Hybrid chemistries (acrylate, PU, epoxy blends)

Best Use Cases

- High-volume, fast-turnaround production

- Temperature-sensitive components

- Selective / mask-free coating

- Complex geometries and fine-pitch boards

- Flexible and wearable electronics

- Optoelectronic and sensor modules

- Field service and touch-up

- Automotive electronics (under-hood / high-vibe)

- Miniaturized and micro-assembly

- Hybrid cure strategies

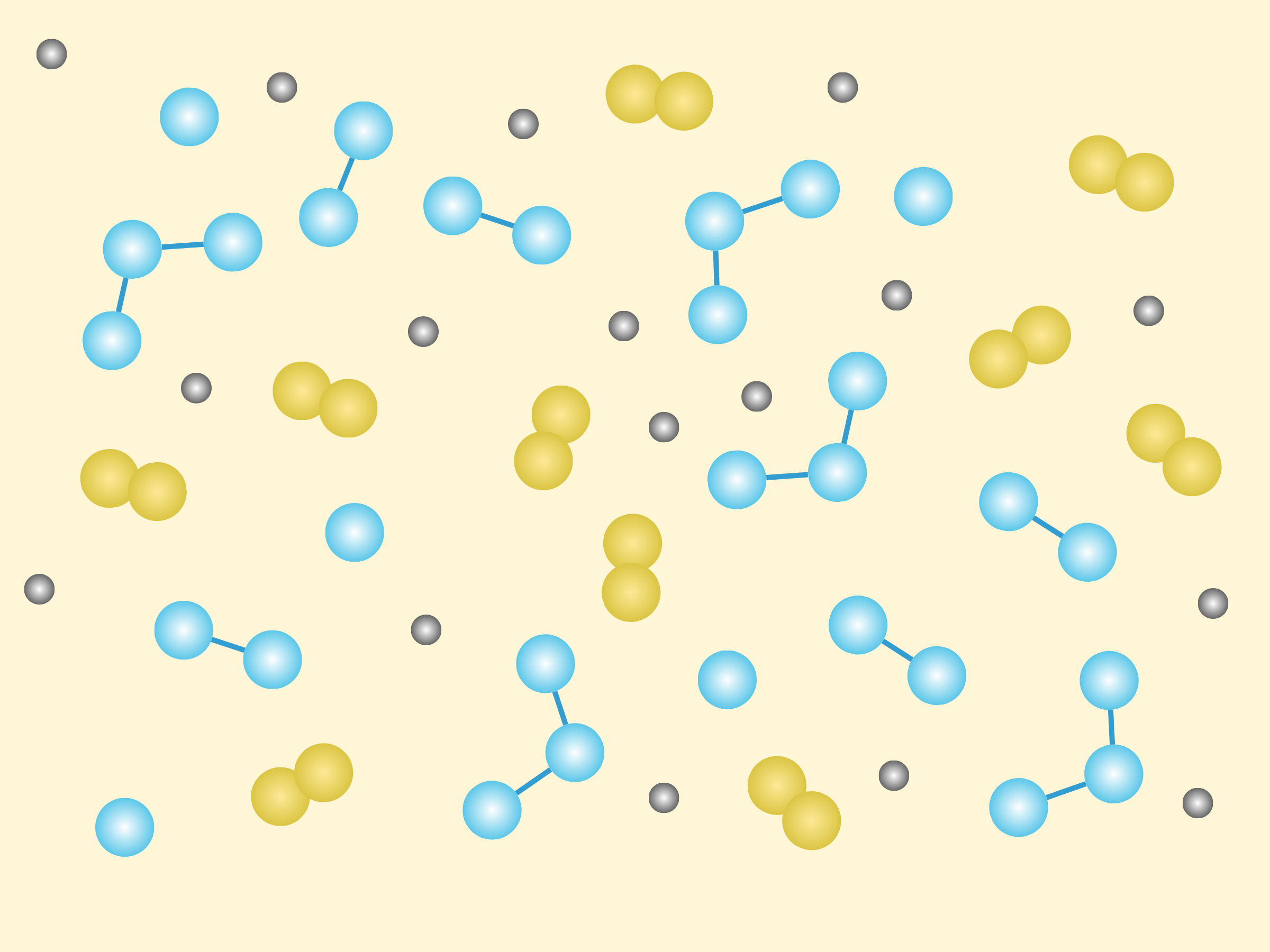

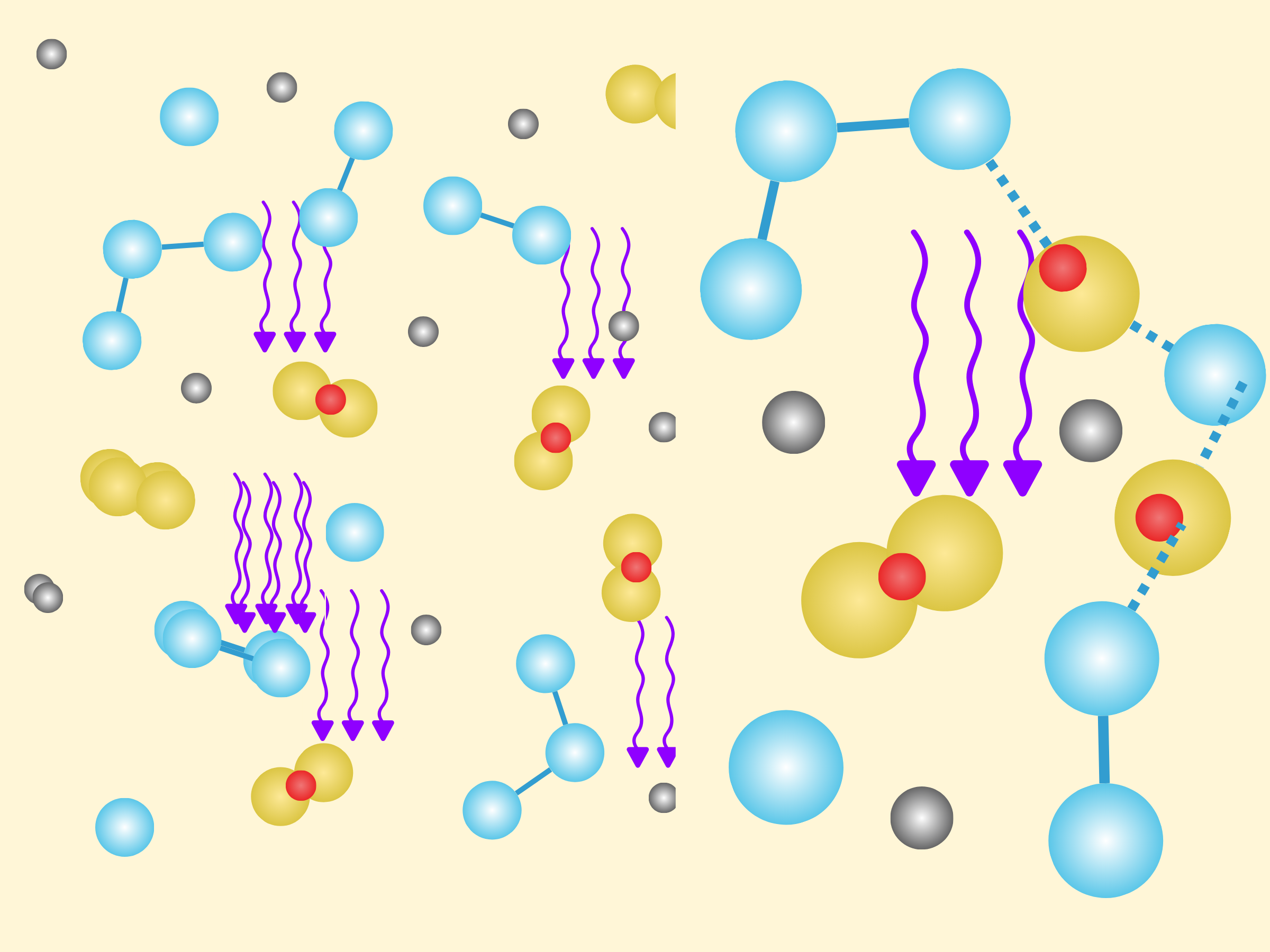

UV-curable Conformal Coatings Cure Mechanism

Pre-cure

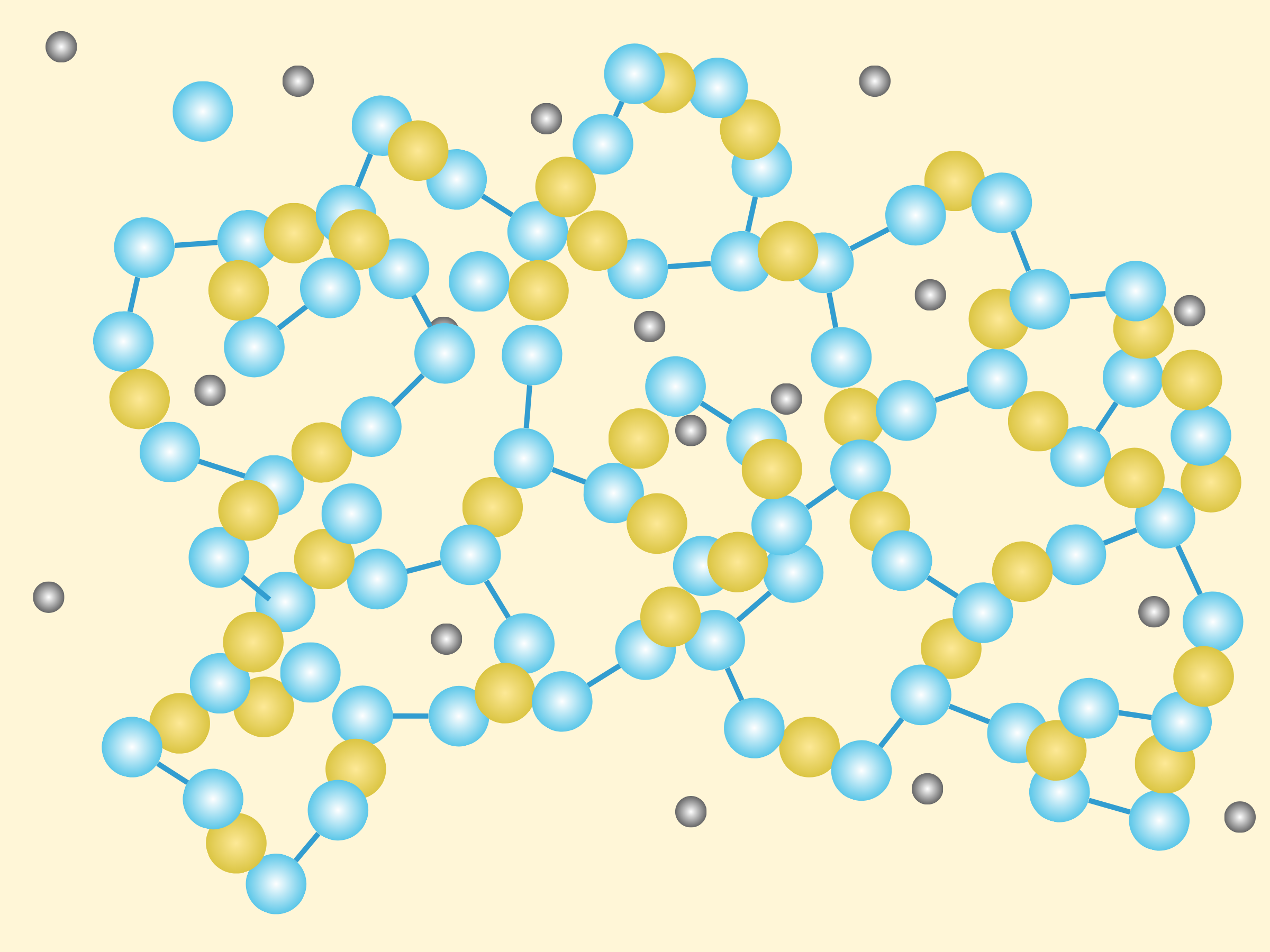

Before any UV exposure, the coating exists as a uniform, liquid film composed of linear oligomer and monomer chains, photoinitiator molecules, and some additives.

UV Light Exposure and Absorption

Photoinitiator molecules absorb UV photons and cleave (radical cure) or generate cations (cationic cure). These reactive species are the “spark” that starts chain-growth polymerization of the acrylate/epoxy groups.

Crosslinking

Multifunctional acrylates link together, forming a three-dimensional network. Within seconds, viscosity spikes as the network percolates, and the film becomes tack-free.

Dual-cure Conformal Coatings

Best Use Cases

- Complex Assemblies: High-pin-count PCBs, connectors, and sensors where full 3D coverage is critical.

- High-Reliability Electronics: Automotive ECUs, medical instruments, and aerospace modules needing both instant cure and long-term durability.

- Inline Production Lines: Facilities seeking to maximize throughput without sacrificing cure completeness or film integrity.

Conformal Coatings Cheat Sheet,

Classification by Cure Mechanism, Typical Chemistries, and Solvent Content

Conformal Coating Application Methods

Applying a conformal coating isn’t a one-size-fits-all decision. If you’re running dozens or thousands of boards, a high-speed spray booth can blanket them in seconds. Need pinpoint accuracy? Robotic dispensers or stencil masks let you coat just the connectors and test points. Dip coating delivers an even film over every surface, while a simple brush or stencil approach is ideal for prototypes and spot repairs. And when only certain areas require protection, selective coating cuts down on waste and cleanup. Ultimately, the best choice comes down to your board’s shape, how tightly you’ve packed components, your production volumes, and how consistent that coating needs to be, so you protect your electronics without slowing down your workflow.

★☆☆☆☆

★☆☆☆☆

★★★★★

★★★★☆

1–10 pcs

$

★★☆☆☆

★★☆☆☆

★★★★★

★★★★☆

1–20 pcs

$

★★☆☆☆

★★☆☆☆

★☆☆☆☆

★★★☆☆

10–100 pcs

$$

★★★★★

★★★★☆

★★★★★

★★★★★

up to 100 pcs

$$$$$

★★★★★

★★★☆☆

★★★★★

★★☆☆☆

50–500 pcs

$$$

★★★★☆

★★★★★

★☆☆☆☆

★★★☆☆

100s–1,000s pcs

$$$

Presentations

Introduction to Conformal Coatings

This presentation provides a comprehensive overview of conformal coatings, exploring their key functions, material chemistries, and application methods.It also covers industry standards for qualification and testing, including IPC-CC-830 and relevant MIL-STD protocols, and concludes with a tailored question set to guide your coating selection based on substrate, environment, throughput, and performance requirements.

Related Blogs

How to Select the Right Conformal Coating

This blog guides you through selecting the right conformal coating by covering key chemistries, performance traits, and application methods. It includes a 30-day corrosive environment case study to illustrate real-world protection. A practical selector chart at the end helps you match coating characteristics to your specific requirements.