Tape and Reel

When using solder spheres in integrated circuits (IC’s) the production process can require a very precise amount and placement of the solder material. IC’s are made in high volumes through an automated process and the different components that are part of the IC are placed using a pick and place machine. Examples of packaging techniques that use solder spheres in the production of IC’s are ball grid arrays (PBGA, CBGA, TBGA and µBGA) and flip chips (C4).

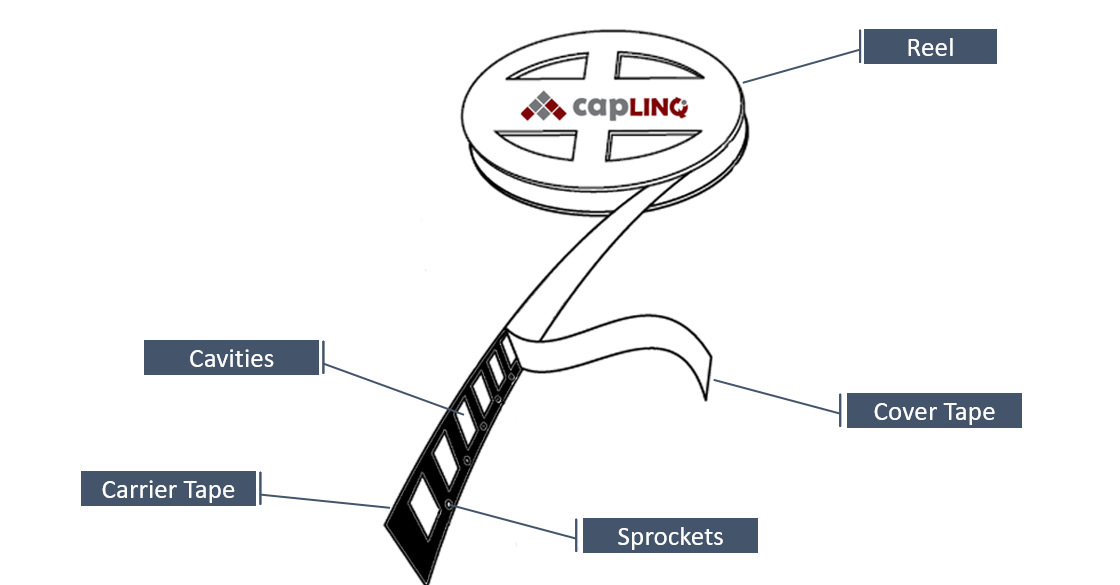

To be able to use our solder spheres in these high volume, automated processes we can package your solder spheres on tape and reel. Our tape and reel solder spheres can be used on almost all existing pick and place tape feeders, which means you can keep using your existing pick and place equipment to ensure your solder material is placed with the right speed and precision. Our tapes and reel packaging service is available for all solder sphere sizes.

Those tape and reels are compatible with most pick and place feeders. Need a specific alloy or preform? Then feel free to contact us for more information. Keep in mind that the minimum order quantities for non existing products will be high. Caplinq offers a wide range of solder spheres and preforms on tape and reel for different applications. We can pack all kinds of solder sphere alloys in various diameters in 7" and 13" reels.

Solder Sphere Tape & Reel Packaging

- Suitable for BGA and flip chip packaging techniques

- Available for our complete range of solder sphere alloys and diameters

- Compatible with almost all existing pick and place feeders

- 8 weeks

SAC305 on 13" Tape & Reel

- Lowest cost Sn/Ag/Cu alloy on tape & reel

- Suitable for BGA and flip chip packaging techniques

- Compatible with almost all existing pick and place feeders

- In stock

SAC305 on 7" Tape & Reel

- SAC 305 on 7 in Tape & Reel

- Designed for Pick & Place

- Available for all sizes of solder spheres

- 2 weeks

Sn63Pb37 on 13" Tape & Reel

- Sn63Pb37 alloy on tape & reel

- Suitable for BGA and flip chip packaging techniques

- Compatible with almost all existing pick and place feeders

- 12 weeks

Bi58Sn42 on 7" Tape & Reel

- Bi58Sn42 on 7 in Tape & Reel

- Designed for Pick & Place

- Available for all sizes of solder spheres

- 6 weeks

Bi58Sn42 on 13" Tape & Reel

- Bi58Sn42 on 13inch Tape & Reel

- Suitable for BGA and flip chip packaging techniques

- Compatible with almost all existing pick and place feeders

- 6 weeks

SAC305 Solder Preforms on Tape & Reel

- SAC 305 on Tape & Reel

- Designed for Pick & Place

- Available for all sizes of solder spheres

- 6 weeks

Copper Core SAC305 on 13" Tape & Reel

- Copper core Sn/Ag/Cu alloy on tape & reel

- Suitable for BGA and flip chip packaging techniques

- Compatible with almost all existing pick and place feeders

- 8 weeks

Sn10Pb90 on 13" Tape & Reel

- Sn10Pb90 alloy on tape & reel

- Suitable for BGA and flip chip packaging techniques

- Compatible with almost all existing pick and place feeders

- 6 weeks

Product Selector Guide

| Alloy | Diameter(mm) | Diameter (mil) | 7" reels | 13" reels |

|---|---|---|---|---|

| SAC 305 | 0.250 | 10 | X | 40,000 |

| SAC 305 | 0.300 | 12 | X | 40,000 |

| SAC 305 | 0.350 | 14 | X | 40,000 |

| SAC 305 | 0.457 | 18 | 10,000 | 40,000 |

| Sn63Pb37 | 0.560 | 22 | X | 20,000 |

| Sn10Pb90 | 0.500 | 20 | X | 40,000 |

| Bi58Sn42 | 0.300 | 12 | 10,000 | 40,000 |

| Bi58Sn42 | 0.500 | 19.6 | 10,000 | 40,000 |

| Alloy | Preform type | Dimensions | 7" pcs | 13" pcs |

|---|---|---|---|---|

| SAC 305 | 0603 | 0.030 x 0.060 x 0.031 | 4,000 | X |

| SAC 305 | 0805 | 0.079 x 0.051 x 0.028 | 4,000 | X |

Frequently Asked Questions

Can I have any Alloy on Tape and Reel?

Generally yes. As long as we are not talking about very small or very large solder spheres then we should be able to pack your alloy into a tape and reel. Custom orders will naturally have a high MOQ so contact us if you need more than 5 reels. We most likely have the alloy that you are looking for and we can quote you individually but we can also offer tape and reel as a service and package your spheres for you.

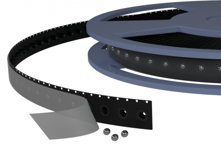

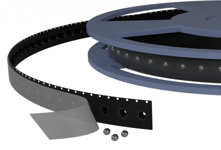

How many spheres can I have into a reel?

This depends on the sphere size. Smaller ones tend to be packed in 40.000 reels while larger ones are usually 10-20.000. It varies very much (tape width 7" - 13" also has an effect) so this is something that we will advise on a per case basis. And no we cannot provide other reel widths. Only 7" and 13", which are compatible with most pick and place machines.

Learn More

CAPLINQ Offers Solder Tape & Reel Packaging Solutions

CAPLINQ offers a wide range of solder spheres and pre-forms on tape and reel for different applications. We can pack all kinds of solder sphere alloys in various diameters in 7" and 13" reels.

When using solder spheres in integrated circuits (IC’s) the production process can require a very precise amount and placement of the solder material. IC’s are made in high volumes through an automated process and the different components that are part of the IC are placed using a pick and place machine. Examples of packaging techniques that use solder spheres in the production of IC’s are ball grid arrays (PBGA, CBGA, TBGA and µBGA) and flip chips (C4).

For custom orders, contact us. Refer to our Product Selector Guide to see our current list of offerings.

How should we initiate the cover tape for tape and reel?

We typically utilize a 3M universal cover tape. This cover tape is the best on the market and provides excellent peel back force. However the cover tape must be initiated where the center portion of the cover tape rips and leaves the glued edges on the carrier tape. If the cover tape is not initiated properly the whole cover tape will be lifted.

The tape is specifically designed to initiate the medial (middle) portion from sealed carrier, instead of conventional methods where the entire width is removed.

When properly aligned:

- Take a pair of scissors and cut the leader (leading edge of package) at an angle of (45°) degrees.

- Using tweezers, position in center of pocket at leader, lift middle portion and peel back at 180 degree angle.

- Cover tape will follow path until it reaches the “design feature” where only the middle portion will initiate and follow scored section (notice feature where peel initiates ~ 1 inch increments).

- Fold the exposed adhesive section over creating a tab (if desired) Note: This step prevents adhesive transfer to feeders

Caution: Peel initiation is achieved in only one direction. Attempting to initiate the peel from the opposite direction will not work. The entire width will be removed, exposing

You can find the full universal instructions for the cover tape application procedure, here

How many spheres can fit on a given reel?

Generally, tape and reel can fit a specific amount of solder spheres depending on the reel diameter.

- 7" reels can take approximately 10,000 - 15,000 spheres, depending on the solder ball diameter

- 13" reels can fit approximately 20,000 - 40,000 spheres, depending on the solder sphere diameter.

This is not an absolute truth but it is a very common starting point for the popular diameters. Of course if the production requires a specific amount of spheres per reel we can accommodate it.

We have been developing a process that maximizes the UPH and quality of the reels and removes any possibility of a human error. Our computer overlords have taken over our jerbs already and allowed us to increase our efficiency and packaging capability. This is done by automated inspection and quality assurance that utilizes Xray and machine vision to make sure that our reels are default free. On top of that, our ESD protected environment ensures that we can take up any sort of tape and reel packaging challenge.

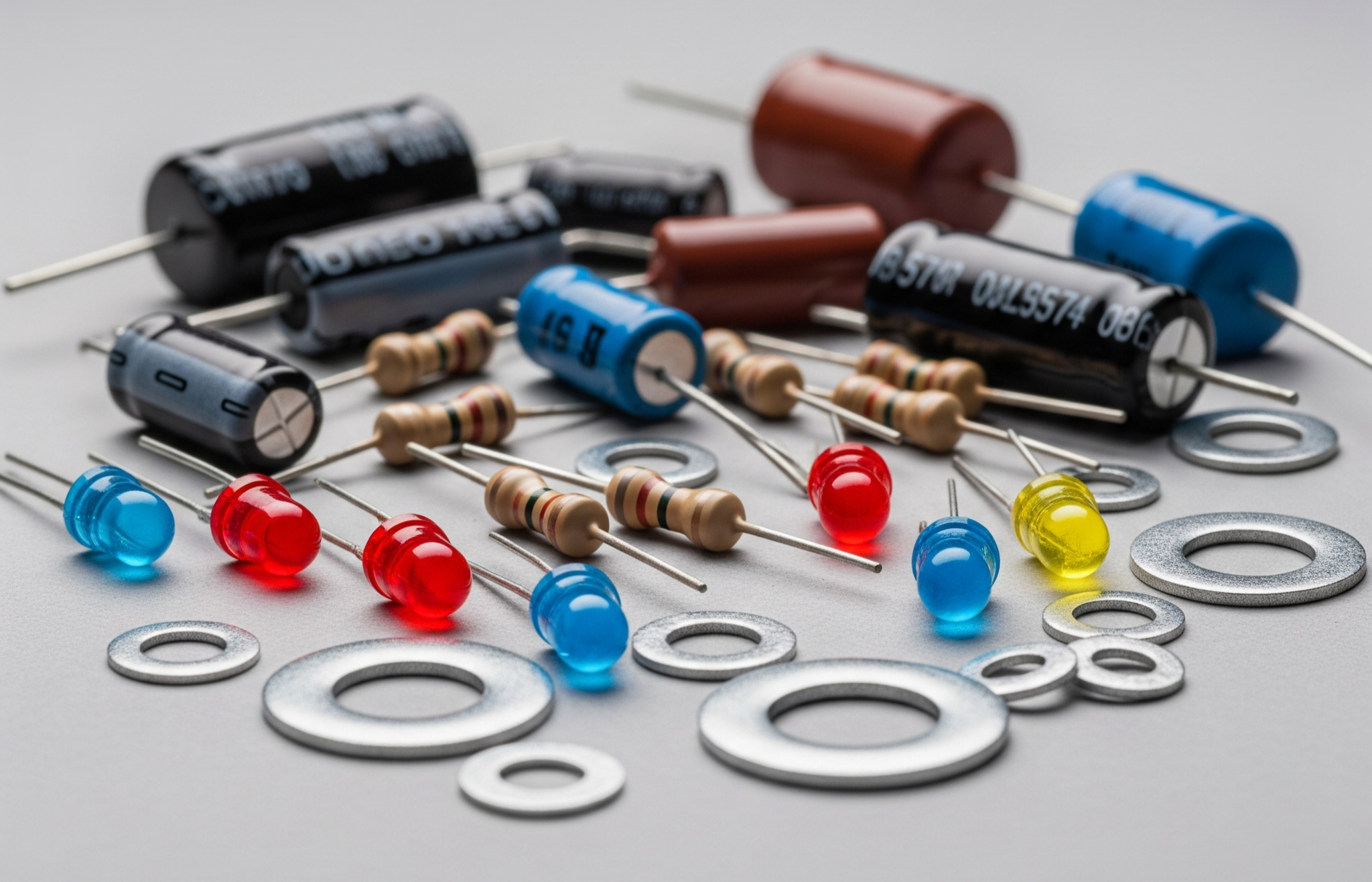

Packaging solutions for other components

While we are specializing in solder spheres, we are not limited to them. We can also pack other components in tape and reel. Some examples are:

- Capacitors

- Resistors

- LEDs

- Washers

- Solder Preforms regardless of size

- Standoffs

- Springs

- Spacers

- SOT, 3,4,5,6 Leads

Do you need to package something not in the list? Contact us for a quick consultation and to see what we can do for you.