Additives

Additives are specialty chemicals that are added to base-chemistries to improve performance. These additives are often blended into the epoxy molding compounds, silicones, epoxy coating powders and other polymers to improve some aspect of performance. CAPLINQ offers a range of specialty additives to be used in our own chemistries or they can be used to improve the performance of your own materials.

A6165 | Electrical conductivity Enhancer

- Improves electrical conductivity

- Soluble in most resin systems

- May improve thermal conductivity

- 2 weeks

MM304 | Methacrylate adhesion promoter Additive

- Mild pleasant odor

- Hydrolytic resistance

- Lower weight loss on cure than IBOMA

- 8 weeks

MM220 | Mono-acrylate monomer

- Low Viscosity

- Low weight loss on cure

- Minimizes cure shrinkage

- 8 weeks

Benzimidazole CAS #51-17-2

- Enhanced Thermal Stability

- Versatile Chemical Base

- Corrosion Protection

- 6 weeks

CS-783 | Methacrylated Epoxy Functional Hybrid Cyclosiloxane

- Low viscosity

- Dual cure mechanism

- Multifunctional

- 12 weeks

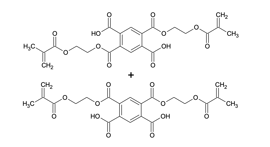

A304 | 4-META adhesion promoter Additive

- Dental Applications

- Adhesion promoter

- Methacryloxyethyl trimellitic anhydride

- 2 weeks

A478-M | PMDM-M adhesion promoter Additive

- Dental Applications

- Adhesion promoter

- Pyromellitic Dianhydride Dimethacrylate

- In stock

A6225| Anti bleed Additive

- Universal additive

- Reduces bleed out on metal surfaces

- Non halogenated

- 2 weeks

A6280 | Anti bleed Additive

- Use in Non-metal-filled systems

- Excellent bleed control on Gold surfaces

- Non halogenated

- 2 weeks

A675-100 | PMDGM adhesion promoter Additive

- Versatile

- Adhesion promoter

- Pyromellitic Dianhydride Glycerol Dimethacrylate Adduct

- 2 weeks

Chemlinq AL20-2B | Triethylenetetramine (TETA)

- Epoxy crosslinking hardener

- Soluble in polar solvents

- Colorless

- 7 days

CS-697 | Polyglycidyl Ether Cyclosiloxane

- Low viscosity

- Compatible with organic resins

- For formulating adhesives

- 2 weeks

Dow Corning Toray SF-8421-EG Fluid

- Epoxy Mold Compound (EMC) additive

- Formulated for compatibility with EMC

- Internal release agent for EMC

- 8 weeks

MM-204 High Tg Mono-Functional Acrylate Monomer

- Hydrolytically resistant

- Low Viscosity

- High Glass Transition Temperature (Tg)

- 2 weeks

MM211 | Maleimide adhesion promoter Additive

- Adhesion promoter

- Flexible aliphatic backbone

- Maleimide and carboxylic groups

- In stock

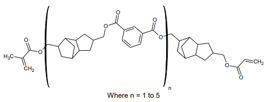

MM281 | Maleimide adhesion promoter Additive

- Adhesion promoter

- Flexible aliphatic backbone

- Long Alkyl chain

- 2 weeks

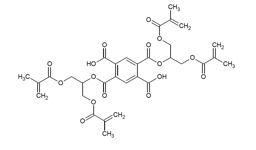

MM290| Acrylate adhesion promoter Additive

- Mild pleasant odor

- Hydrolytic resistance

- Lower weight loss on cure than IBOA

- 2 weeks

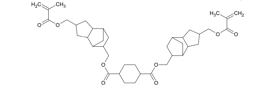

PEAM-1044 Low warpage Polyester Acrylate/Methacrylate

- Thermally stable

- Low warpage

- High adhesion to various substrates

- 2 weeks

PEAM-1769 Difunctional (meth)acrylate

- Ultra low modulus

- Thermal stability

- High adhesion to various substrates

- 2 weeks

PEAM-645 High Tg Polyester Acrylate/Methacrylate

- High Tg

- Low CTE

- High adhesion to various substrates

- 2 weeks

Product Selector Guide

Anti-bleed Additive

| Product | Chemistry/Description | Application/Features |

| A1050 | Antibleed Additive | Non halogenated | Superior compatibility with metal filler systems such as silver. Improved bleeding properties: Non-metal filled systems ex. silica |

| A1100 | Antibleed Additive | Non halogenated | Designed for metal surfaces with more acid functionality. Improved bleeding properties: Non-metal filled systems ex. silica Recommended formulation: 0.5% - 1.0% |

| A6225 | Antibleed Additive | Non halogenated | Universal additive | Excellent compatibility: Silver Improved bleeding properties: Non-metal filled systems ex. silica It also provide mold release and surface atnti stiction properties. Recommended formulation: 2% - 4% |

| A6280 | Antibleed Additive | Non halogenated | Excellent compatibility: Gold surfaces Designed for Non-metal filled systems Minimal or no affect on the adhesion properties of the formulation.Recommended formulation: 0.5% - 1.0% |

| A6165 | Electrical Conductivity Enhancer | Use as an additive in combination with metal fillers (e.g. silver or Ag coated Cu) to further |

Adhesion Promoter Additive

| Product | Chemistry/Description | Application/Features |

| A304 | 4-Meta (Methacryloxyethyl trimellitic anhydride) Adhesion Promoter Additive | Reactive Primer specific for dental application Enhance monomer penetration into dentin pretreated with 10% citric acid and 3% ferric chloride |

| A478-M | PMDM-M (Pyromellitic Dianhydride Dimethacrylate) Adhesion Promoter Additive | PMDM-M chemistry is a cheaper option for dental adhesive application |

| A675-100 | PMDGM (Pyromellitic Dianhydride Glycerol Dimethacrylate Adduct) Adhesion Promoter Additive | Adhesion enhancement where four methacrylate groups and two carboxylic groups per molecule allow bonding to a variety surfaces. |

| MM211 | Maleimide Adhesion Promoter Additive | Flexible Aliphatic backbone | Use as intermediate for the synthesis of ester and amide linked thermoset monomers, as well as maleimide functional resins |

| MM281 | Maleimide Adhesion Promoter Additive | Flexible Aliphatic backbone | Long Aklyl Chain | Main difference from MM211 is the twice as long alkyl chain |

| MM290 | Acrylate Adhesion Promoter | Use in UV or peroxide cure formulations and applications that require hydrolytic resistance | Mild odor |

| MM304 | Methacrylate adhesion promoter Additive | Use as a reactive diluent monomer for use in UV or peroxide cure formulations. |

Base Resin

| Product | Chemistry/Description | Application/Features |

| PEAM-1044 | Low warpage Polyester Acrylate/Methacrylate | High thermal stability and low volatility | Use as a base resin in a formulation or an additive | Exceptionally low warpage with the addition of polybutadiene type resins |

| PEAM-1769 | Difunctional (meth)acrylate | Use as a base resin or an additive to reduce stress | Excellent adhesion on most substrates with low stress and low shrinkage due to its high Tg polycyclic repeat units. |

| PEAM-645 | High Tg Polyester Acrylate/Methacrylate | Use as a base resin in adhesive applications or coating applications | Exhibits low CTE, high Tg, and high modulus. |

| PEM-665 | Methacrylate terminated polyester | Use as a base resin in dental applications | Good solubility in both aliphatic and aromatic co-monomers. |

Universal Additive

| Product | Chemistry/Description | Application/Features |

| Benzimidazole | Benzimidazole | Latent curing Agent For Epoxy Resins | Reacts at elevated temperatures makes it ideal for enhancing the thermal stability and mechanical properties of epoxy mold compounds. |

| CHEMLINQ AL20-2B | Triethylenetetramine (TETA) | Corrosion Inhibitor | Accelerate Curing Process | Fuel Additive | Premier epoxy curing agent that accelerates the curing process and can produce durable coatings in adhesives, composites, and coatings |

| CS-697 | Polyglycidyl Ether Cyclosiloxane | For Adhesive formulation base resin with compatibility with most organic resins. |

| CS-783 | Methacrylated, Epoxy-functional Hybrid Cyclosiloxane Monomer Adhesion Enhancer Additive | Used primarily as an adhesion promoter for mold compounds, metal surfaces, and polyimides by improving interfacial bonding |

| Dow Corning Toray SF-8421 | EG Fluid | EMC Internal Release Agent Additive | Formulated for compatibility with EMC wherein the main purpose is to reduce stress and improve flowability of the mold compound | Excellent compatibility with epoxies and silicones |

| MM204 | High Tg Mono-Functional Acrylate Monomer | Use as a reactive diluent for UV or peroxide cured resins, coatings or adhesives | Improve stereolithographic processes for high-temperature applications. |

| MM220 | Low viscosity mono-acrylate monomer | Use as reactive diluent for UV or peroxide cured resins, coatings and adhesives | Polycyclic ring structure helps minimize shrinkage on cure |

| U-847 | high-purity, methacrylate-modified urethane monomeR | Use in advanced light-cure formulations | No BPA backbone |