Molding Compounds

Molding Compounds are thermosetting plastics with very good mechanical, electrical insulation and temperature resistance properties. Depending on their chemistry, hardeners, additives, filler and filler cut size, molding compounds are destined for different applications. Epoxy molding compounds (EMC) are our main focus but there are also Bulk molding compounds and Sheet molding compounds, mainly composed by polyester or vinyl ester.

Epoxy molding compounds (EMC), known also as Epoxy resins or Duroplast are used extensively in the semiconductor, electronics and automotive industries to replace more expensive ceramics, metals and other plastics. They are mainly Silica or Fiberglass filled with various additives such as bismaleimides and anti bleeds that contribute to their thermal and mechanical properties. Caplinq, being a specialised chemicals distributor, mainly focuses on industrial, automotive, optoelectronic and semiconductor epoxy molding compounds.

Please continue to our Learn More section to learn more about which epoxy molding compounds are available, the differences in their types and application methods, and how CAPLINQ can help you select and order the compound that is right for your application.

Frequently Asked Questions

What are the recommended dimensions of mold vents?

Mold venting dimensions depend very much on the size of the molded part. For large parts using a lot of epoxy mold compound per part, the vents are much larger than for example semiconductor molded parts. In general, on large parts, "generous" vents are recommended. This means that vent scars on larger parts are not so critical and neither is flash as long as the air is forced out.

It\'s difficult to be specific as to depth but 150 - 200 microns are figures that are typical. The wider the mold vents the better, with 5 mm or more depending on the mold layout. Double vents used to be quite common. A mold tool designer should have various rules of thumb and really is the one to decide on what is required for each epoxy mold.

Transfer molding vs. compression molding

There are two basic application methods of applying epoxy molding compound: transfer molding and compression molding.

Transfer molding means that the parts are pressed through a "cull" to a runner which then runs to the part cavities to be filled.

Compression molding, on the other hand, the bottom of the mold is the bottom of the part, and the epoxy is fed into the cavity. The top of the mold is brough down on top, forming the top of the part.

What is an Acetone test for EMC?

We regularly test our EMC for agglomerate particles. While a very rare occurrence, it can happen so we have quality testing in place. An acetone test, otherwise known as hard spot test, is a standard test method employed by our QC Dept. to detect and capture agglomerate in mold compoundS.

The test starts by putting the mold compound in acetone. Organic components will dissolve in it while inorganic components (mainly silica filler) and agglomerate particles will remain undissolved. By running the solution through a combination of sieves with different mesh sizes we are able to catch any agglomerate particles in the sieve and determine whether the EMC was contaminated or not.

Wouldn\'t electrically conductive fillers provide better thermal conductivity?

Yes, they would. However, there is an implicit understanding when epoxy mold compound manufacturers refer to "thermally conductive" EMCs. What they are actually saying is "thermally conductive and yet still electrically insulating".

The reason is because functional epoxy mold compounds used for semiconductor encapsulation have a first, basic function - and that is to electrically insulate. Once this basic need is provided, we can look at providing thermal conductivity, which rules out electrically conductive fillers.

What is the highest Tg possible for an EMC?

Base epoxies probably have a current maximum Tg of around 255°C. When combined with other resins, hardeners and polymers, we have seen thermosetting polymers with a Tg as high as 454°C, though this material is not designed for semiconductor encapsulation.

Can Epoxy Mold Compounds be used in applications that are above their Tg?

Absolutely. An epoxy\'s glass transition temperature is not the same as its maximum operating temperature. Some materials, such as silicones have glass transition temperatures that rare low, or even negative and yet can have maximum operating temperatures higher than epoxies.

What is the best material to use for high thermal conductivity in Epoxy Mold Compounds?

If price was not a concern, diamond would be the best thermally conductive filler to use. It has a bulk thermal conductivity of 2200 W/mK and mixes well with epoxy resins to offer excellent flow properties.

Furthermore, it is an excellent electrical insulator. Unfortunately, the price for such a compound would be upwards of $7500/kg which makes it far too expensive for practical applications.

When the filler density and the crosslink density of different resins are different, in which way it affects the resin properties?

For filler density, specifically, the use of silica fillers has the following impacts on molding compound properties:

- Reduced: Shrinkage (thus, thermal stress), CTE & Water Absorption, formulation cost, exothermic property

- Improved: toughness & abrasion resistance & Thermal conductivity, heat deflection temperature, modulus

- Increased: Viscosity & Weight & Dielectric Constant & Matching Difficulties

| Application | Key Properties | ||||||

|---|---|---|---|---|---|---|---|

| Attributes | Main Colors | Filler Type | Cure Chemistry | Glass Transition Temperature (Tg), °C | CTE, Alpha 1 ppm/°C | CTE, Alpha 2 ppm/°C | |

| Industrial | Thermal shock and mechanical resistance | Black | Fiberglass | Anhydride | 105 - 161 | 17 - 42 | 50 - 118 |

| Semiconductor | Fine filled and Electrically stable | Black, Gold | Silica | Phenolics | 162 - 191 | 18 - 21 | 60 - 70 |

| Optoelectronics | Highly reflective and transmissive | White, Clear | Proprietary | Hybrid | 137 - 151 | 41 - 81 | 90 - 167 |

*All properties are indicative. There are other colors/cure chemistries and filler types for each category but the table points out the main application characteristics.

| Pellet Diameter | Pellet Weight Range (grams) | |||

|---|---|---|---|---|

| Type | Millimeters | Inches | Minimum | Maximum |

| Micro Pellets | 5 | 0.197 | 0.2 | 0.4 |

| 5.7 | 0.224 | 0.35 | 0.55 | |

| 8.5 | 0.335 | 0.8 | 1.2 | |

| Mini Pellets | 11 | 0.433 | 1.5 | 4.5 |

| 13 | 0.512 | 2 | 6 | |

| 14 | 0.551 | 2.5 | 7.5 | |

| 14.3 | 0.563 | 2.5 | 8.5 | |

| 16 | 0.63 | 3.5 | 12 | |

| 18 | 0.709 | 4 | 16 | |

| 20 | 0.787 | 5 | 20 | |

| 25 | 0.984 | 8 | 30 | |

| Conventional Pellets | 35 | 1.375 | 20 | 70 |

| 38 | 1.496 | 25 | 85 | |

| 40.6 | 1.6 | 20 | 160 | |

| 45 | 1.75 | 35 | 120 | |

| 48 | 1.9 | 40 | 135 | |

| 55 | 2.165 | 50 | 180 | |

| 58 | 2.28 | 40 | 380 | |

| 61 | 2.4 | 45 | 400 | |

Learn More

Application Methods | Reliability & Standards |

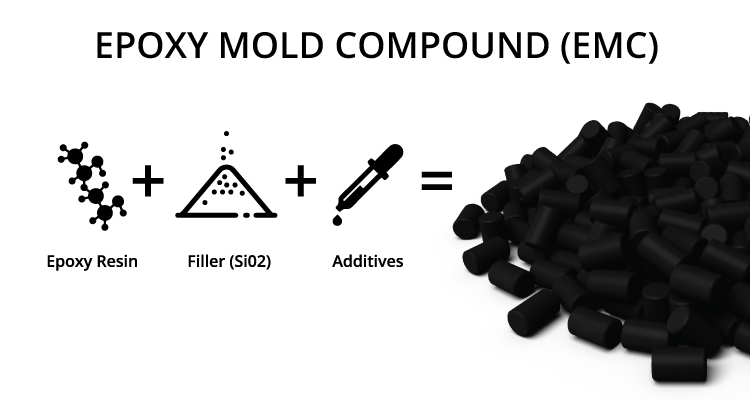

Epoxy Mold Compounds (EMC) are formulations of thermosetting solid epoxy polymers, additives, and silica-based fillers.

EMCs are used in industrial molding applications and commonly come in the form of compressed solid powder pellets which are then heated into a liquid and molded to encapsulate or “package” a semiconductor or electronic device.

The final mold form of Thermosets is permanent

They won’t melt again even at higher temperatures than their original melting point. This makes them perfect for high-temperature applications including circuit board devices which have to go through a solder reflow process of up to 260°C.

Epoxy is produced by combining epichlorohydrin with a Curative (hardener).

The most common curatives are Bisphenol-A (DGEBA), Bisphenol-F (DGEBF). However, other curatives are also used: including Phenols, Thiols, Anhydrides, Amines, Aliphatic Alcohols. Depending on the curative and the ratio of curative to epichlorohydrin the resulting resins can have a variety of molecular weights, viscosity, and final material properties.

The final result is usually a complex crosslinked long-chain molecule polymer network with great strength, and high thermal and chemical resistance, fast cure time, and low viscosity. Combining it with a silica filler dramatically lowers CTE, increases density, and creates a mechanically strong and incredibly insulating composite perfect for insulating and protecting even the most sensitive electric devices.

Hardeners and Curatives.

Different curatives produce different kinds of epoxy resins with different properties. For example, Bisphenol epoxy resins are most commonly used as a base for adhesives and coatings. Epoxy Mold Compounds (EMC) on the other hand are usually a formulation of either anhydride epoxy resin or phenolic epoxy resins, along with other additives, and including a high percentage silica-based filler (60%--90%).

Epoxy resins cured with anhydrides have low viscosity, high latency, and have amazing cured strength

This makes them perfect for Industrial EMC for molding larger and more massive parts that require higher mechanical strength. However, anhydride epoxies generally have high moisture absorption which makes them less suited to more sensitive electrical applications like semiconductors.

Phenol curatives form highly crosslinked polymer networks: and so have outstanding high temperature and chemical resistance and lower moisture absorption.

That's why phenolic epoxy resins are perfect in Semiconductor Epoxy Mold Compounds because they can easily survive even SAC solder reflow temperatures (260 °C). This makes phenolic epoxy resin based EMC the standard for semiconductor encapsulation and other high-temperature applications.

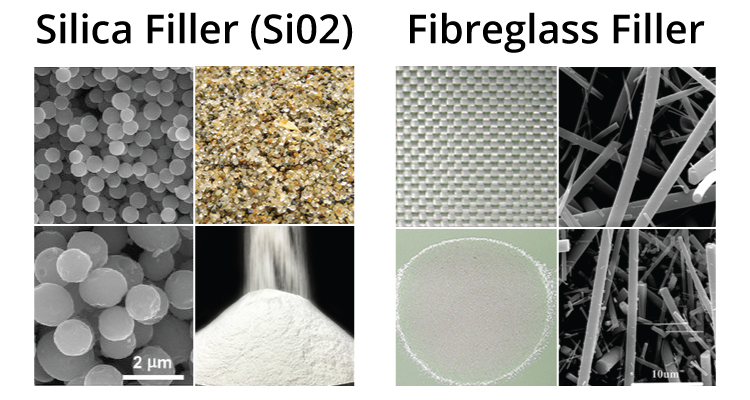

Fillers

Different filler types also dramatically affect the final properties of the resulting EMC composite. For example, adding iron filler creates EMC with higher thermal conductivity and other magnetic properties, whereas silica filler increases the strength and insulation of the final composite.

One important reason silica fillers are the most used mineral filler in EMC composites is that silica has an incredibly low coefficient of thermal expansion (CTE).

Epoxy resin by itself has a CTE of 300ppm/°C, while silica has a CTE of 3ppm/°C

Combining the two creates a final composite with a CTE of around 60ppm/°C in a ratio of 80% filler to 20% epoxy resin.

Having a low CTE EMC is important to ensure that the Epoxy Mold Compound packet and the semiconductor or electric device inside expand and contract at the same rate under thermal stress otherwise delamination will occur.

Silica filler comes in two main types: Fibreglass and silica sand.

Fiberglass, like all glass, is silica based and generally has a higher particle size. Fiberglass fibers create an interlocking structure giving increased mechanical strength, however, it has a much larger particle size and higher viscosity because fiber is unable to flow very well in the molten composite.

Not just the filler type, but filler particle size and ratio have an important impact on the final performance of any given EMC.

Silica sand, on the other hand, has a smaller particle size, and particles that are more spherical and so flow better when the composite is molten. Smaller gate size 100 microns, a general rule filler particle size needs to be less than 1/3 the gate size.

Filler particle size may be the most important variable when it comes to selecting an Epoxy Mold Compound

In the EMC molding process, the solid epoxy molding compound is heated to become a liquid and then must flow through runners and gates of the mold plate that direct it into the mold cavity. Transfer molding plates for semiconductors can have gate sizes as small as 100 microns. Fiberglass filler can have particle sizes of 100 microns so are clearly incompatible. Silica Sand can have particle sizes of less than a micro making it the perfect choice for semiconductor encapsulation.

Industrial EMC VS Semiconductor EMC

So as you can tell Epoxy Mold Compounds tend to fall in two groups.

There are Industrial Epoxy Mold Compounds that are composites of Anhydride epoxy resins with fiberglass filler. There are best suited for molding more massive parts that require high mechanical strength.

And there are Semiconductor Epoxy molding compounds: usually a composite of Phenolic epoxy resins with silica sand filler which are best suited more demanding and complex semiconductor encapsulation. The smaller particle size of the silica sand being able to pass through the smaller gate size of transfer mold is not the only reason this is so.

Phenolic epoxy resins also have better temperature and chemical resistance than Anhydride epoxy resins making them able to withstand the solder reflow heating process better. They also have better lower moisture absorption.

Key Properties

Moisture Absorption

EMC Semiconductors have to meet much higher requirements formalized in the industry as MSL standards. Moisture absorption is one the most important factors: trapped moisture within the epoxy molding compound expands explosively as steam and literally cause the encapsulated semiconductor to explode like a popcorn.

That's why depending on epoxy resin type and silica filler type, epoxy mold compounds are suited for either industrial product molding or semiconductor molding.

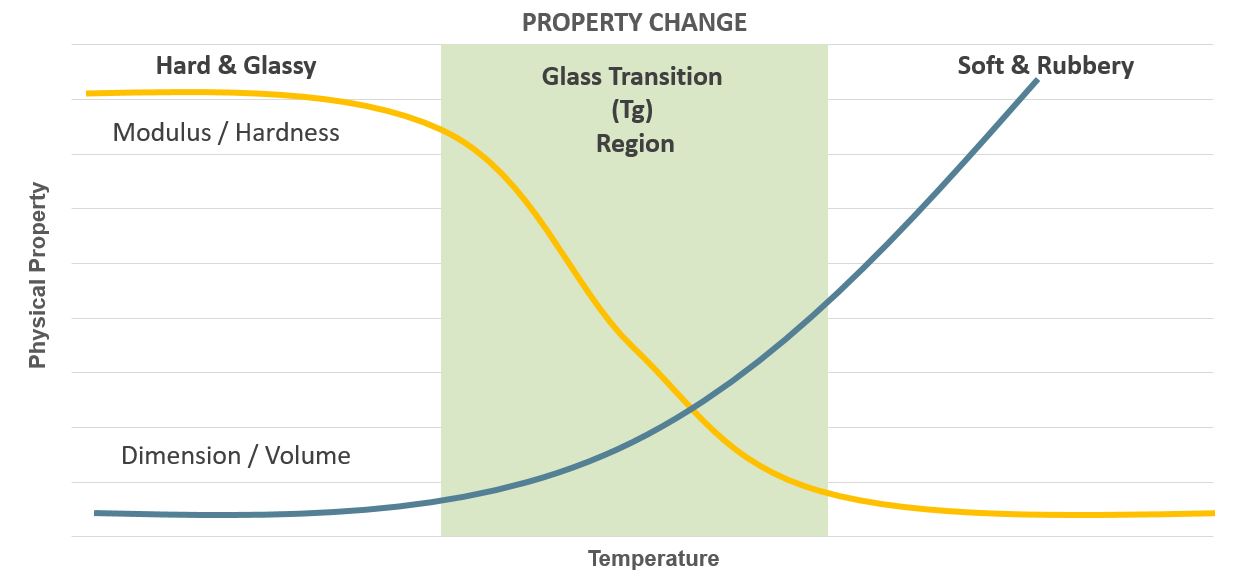

Glass Transition Temperature (Tg)

As explained in the article on how epoxy mold compounds cure, the glass transition temperature (Tg) of an epoxy molding compound is the temperature above which epoxy properties, specifically the coefficient of thermal expansion (CTE) and the dynamic modulus (E), change.

As you can see in Figure 1, the glass transition temperature, though often presented on technical data sheets as a single value is actually more accurately defined as a range. On the left side of the range, the epoxy mold compounds exhibit a hard or glassy behavior, characterized by a high modulus, high hardness and high stiffness. On the right side of the glass transition temperature the epoxy mold compound has a lower modulus, lower hardness and lower stiffness.

Similarly, the lower line represents the dimension or volume of the EMC. On the left of the glass transition region, the coefficient of thermal expansion (CTE), measured in parts per million per degree Celcius (or ppm/°C) is linear and its rate ofd expansion increases more slowly. On the right side of the Tg region, the CTE increases much more quickly, typically 3 to 4 times as much in the case of epoxy molding compounds.

Comparative Tracking Index

As the progress of semiconductor packages continuously moves towards high voltage, high power, and high frequency, insulation becomes nonnegotiable. Comparative Tracking Index (CTI) measures a material’s resistance to electrical tracking—the formation of a conductive carbonized path on the surface of an insulator under moisture and voltage stress.

| Tracking Index (V) | Material Group | PLC |

|---|---|---|

| 600 and Greater | I | 0 |

| 400 through 599 | II | 1 |

| 250 through 399 | III | 2 |

| 175 through 249 | IIIa | 3 |

| 100 through 174 | IIIb | 4 |

| < 100 | - | 5 |

Comparative Tracking Index (CTI) test determines the maximum voltage at which the material resists tracking after 50 drops of 0.1 % ammonium chloride solution have fallen between two electrodes placed on the surface of a 3 mm thick specimen.

CTI result is expressed in volts and categorized into Performance Level Categories (PLC) and Material Group to standardize material classification.

A high CTI value indicates strong resistance to surface leakage and tracking, allowing reduced creepage distances and safer design in high-voltage or humid environments. Epoxy molding compounds with CTI ≥ 600 V (PLC 0) are ideal for power modules, relays, automotive control units, and high-reliability semiconductor packages. Conversely, materials with CTI < 250 V (PLC ≥ 3) require greater creepage distances or environmental protection to prevent arcing and insulation failure.

Product Handling Guide

Protection from Heat & Humidity

Epoxy Molding Compounds (EMC) are affected by heat and moisture. That is why we require refrigeration during shipping, handling, and storage.

Epoxy Mold Compounds are shipped in plastic bags packed in carton boxes. The plastic bags keep the condensation and humidity from coming into contact with EMC and should only be opened and closed when the epoxy is at room temperature to avoid condensation formation when moving the products from cold storage to warmer temperatures.

Upon recieving the products, move the products into cold storage. When you receive your goods, they should be placed into cold storage as soon as possible. CAPLINQ recommends materials be stored at or below the storage temperatures indicated on the technical data sheets. Lower temperatures are even better to maximize flow retention.

Storage Instructions

Store Epoxy Molding Compound (EMC) as cool as possible. Epoxy molding compounds are mixed systems wherein the cross-linking reaction is initiated at the time of manufacturing. This reaction causes the flow retention to drop, meaning it flows less during molding. Once started, the reaction cannot be stopped, only slowed down. This rate of reaction is dependent on two factors: time and temperature

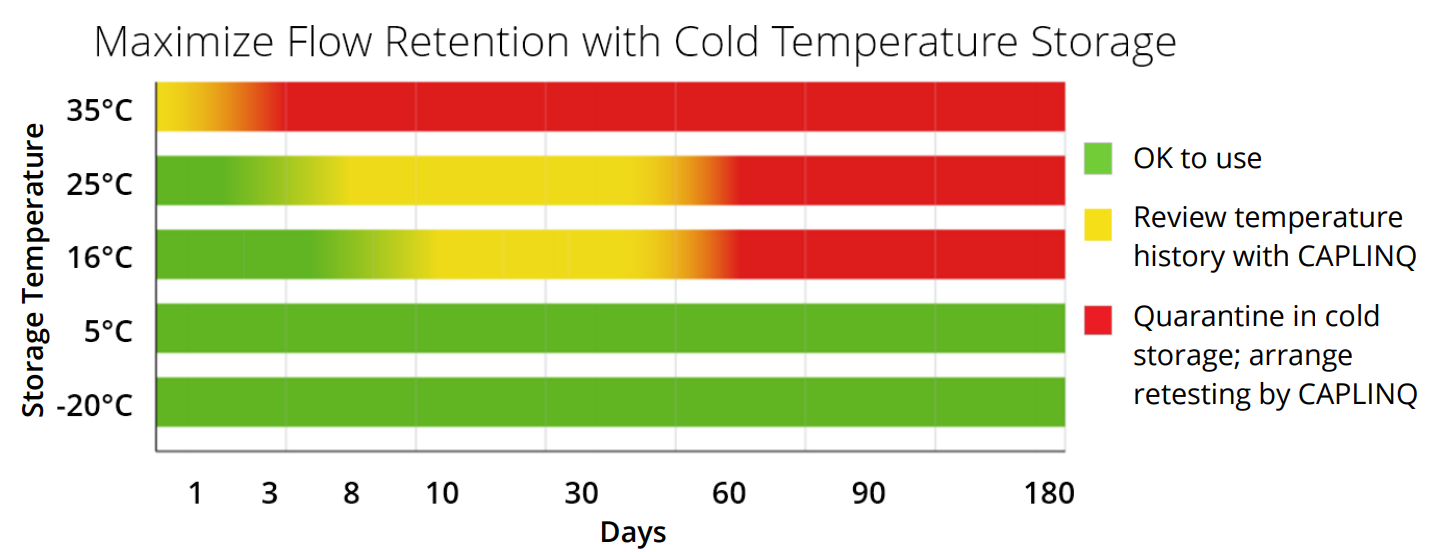

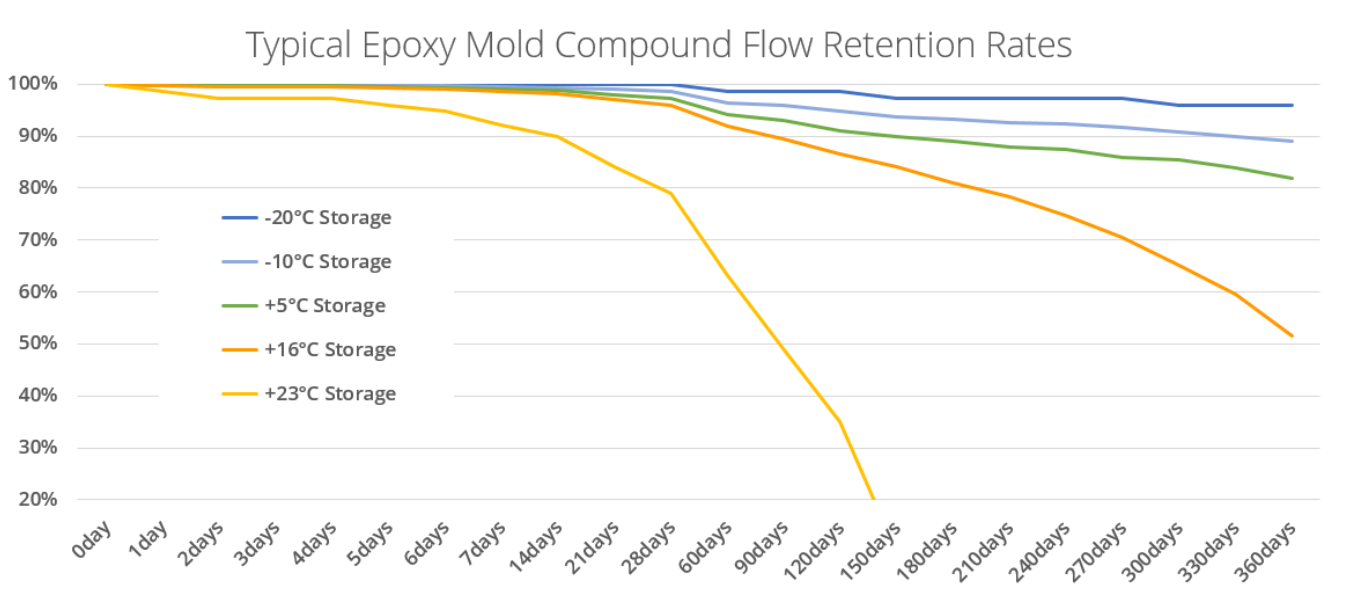

Storing epoxy molding compounds at lower temperatures slows down the reaction significantly. Though the rate of reaction is different for every product, the chart below gives a good idea of what happens to mold compound flow retention at various storage temperatures. Though CAPLINQ typically recommends a storage temperature at or below the temperature listed on the technical data sheet, you can see from below chart that lower temperatures have an even more positive on flow retention rates.

Usage Instructions

- Remove Epoxy Molding Compound from cold storage. Epoxy Molding Compounds must be brought to ambient temperature before use. The time for temperature equilibration depends on the mass of material being prepared for use. A 15kg box of EMC stored at 5°C needs approximately 4 hours to equilibrate. Boxes stored at colder temperatures need longer times. CAPLINQ typically recommends taking EMC from cold storage 8 – 24 hours before use. Use product within 48 hours.

- Do NOT open plastic bag before thawing. Condensation may form on the box and the bag of the EMC when brought to temperature to equilibrate. This is normal and poses no problems. If the bag is opened, condensation may form on the pellets, this may cause molding issues. Keep the bag closed until ready for use.

- Do NOT return unused product to cool storage. It is not advised for unused product to be returned to cold storage. Though it is possible to refreeze and re-thaw the EMC, it is very difficult to measure the remaining flow retention and thus, CAPLINQ voids all warranties in these cases. If you do choose to do this, make sure the plastic bags is well sealed prior to returning to cold storage to avoid condensation.