Low pressure molding

Electronic components must be shielded from high temperatures, chemicals, and moisture, but conventional injection mold bonding and encapsulation production processes are time-consuming and have design constraints. Low-Pressure Molding (LPM) is a manufacturing process ideal for encapsulating and protecting delicate electronic components, including printed circuit boards [PCBs], automotive components, mobile phone batteries, wiring harnesses, connectors, switches, sensors, control units, antennas, cables and many other crucial components. Unlike traditional injection molding or potting, LPM utilizes significantly lower pressure and heat, making it perfect for sensitive electronics that wouldn't withstand harsher environments.

LPM typically uses thermoplastic materials with low viscosity, allowing for over-molding and encapsulation of even the most sensitive PCB assembly. Since the ingredients are natural adhesives, the procedure works well for sealing circuitry against moisture, dust, and grime, often up to an IP-68 classification.

Thermelt 867 | Low Pressure Molding (LPM)

- Molding resin suitable for automotive applications

- Good versatility for broad process and performance

- Flammability UL94:V0

- 12 weeks

Thermelt 858 | Low Pressure Molding (LPM)

- Enhanced UV resistance versus standard PA

- High hardness and cohesion

- Flammability UL94:V0

- 12 weeks

Thermelt 195 | Low Pressure Molding (LPM)

- Industrial

- High hardness / strength

- Flammability UL94:V2

- 12 weeks

Thermelt 865 | Low Pressure Molding (LPM)

- Excellent adhesion

- Good brittleness resistance at low temperature

- Flammability UL94:V0

- 12 weeks

Product Selector Guide

| Product | Operating Range (°C) | Shore Hardness (ISO 868) (Instant/15s) | Viscosity at 25°C (Pa.s) | Softening Point (°C) (ASTM D3461) | Typical Characteristic |

| BS-867 | -40°C to 150°C | 38/27 D | 3.0-4.0 | 183°C ±5°C | General-purpose high-performance moldable polyamide with good adhesion and environmental and thermal shock resistance. Used for applications such as automotive exteriors. |

| BS-858 | -40°C to 150°C | 40/32 D | 4.0-6.0 | 180°C ±5°C | Moldable polyamide with very good thermal stability as well as UV and moisture resistance. Available in black only. |

| BS-195 | -20°C to 150°C | 45/40 D | 3.0-4.0 | 200°C ±5°C | Moldable polyamide with excellent thermal stability and increased hardness for electronics over-molding. |

| BS-865 | -55°C to 120°C | 30/16 D | 2.5-3.5 | 157°C ±5°C | Moldable polyamide with very good low-temperature resistance and good adhesion for automotive applications. |

Frequently Asked Questions

What are the benefits of LPM?

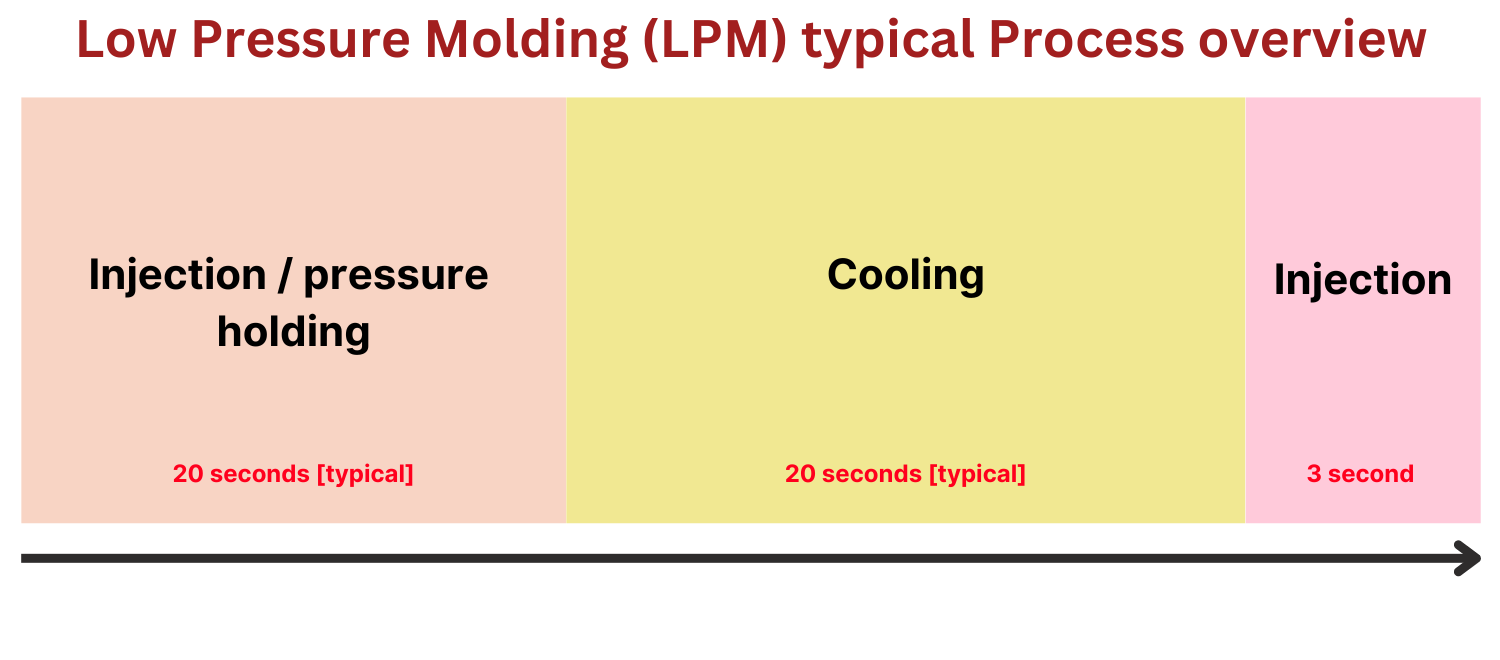

Faster cycle time: Low-pressure molding offers a significant advantage over potting by streamlining the process into just three steps compared to potting's eight, leading to faster production times and lower costs.

Reduced material waste: LPM uses a closed-loop system, minimizing material waste and environmental impact.

Excellent protection: LPM provides superior encapsulation, achieving IP ratings up to IP68 in some cases.

Gentler on electronics: Lower pressure and heat minimize stress on delicate components.

Does the low-pressure molding require housings for the components?

No, a separate housing typically isn't required for low-pressure molding. The molded material itself acts as the housing, protecting the components and eliminating extra parts. This simplifies manufacturing and can even improve the final product's appearance.

Learn More

How does LPM process work?

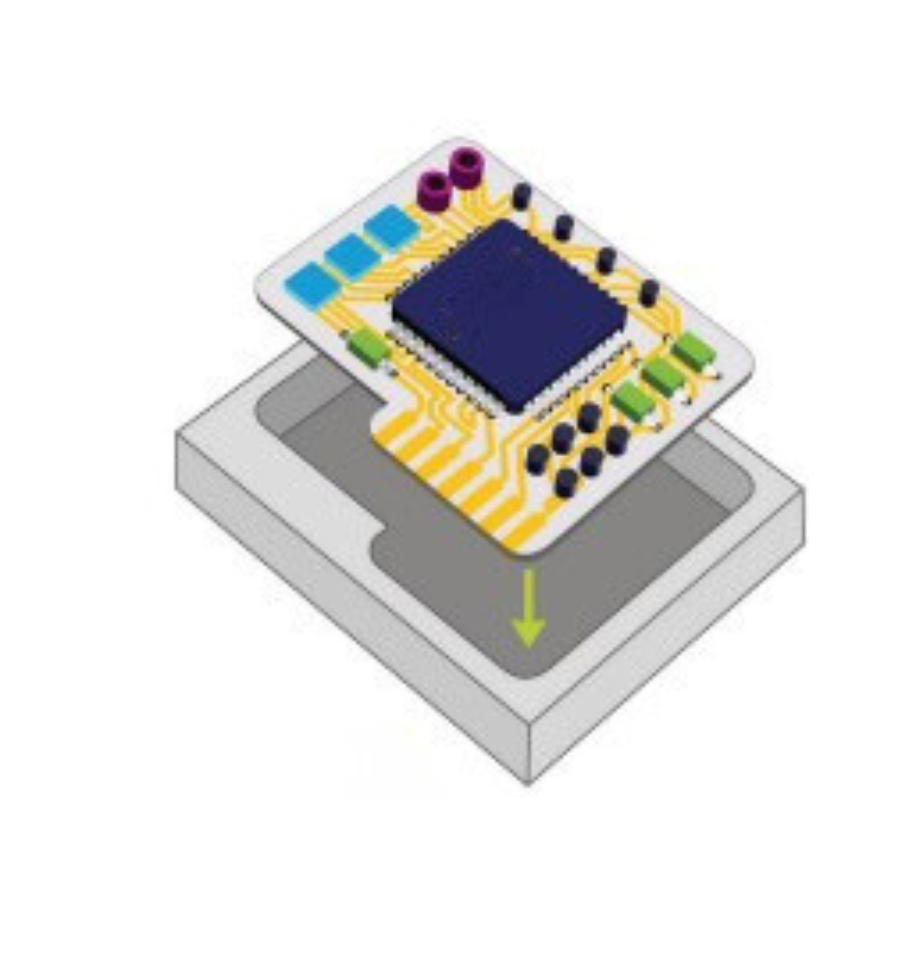

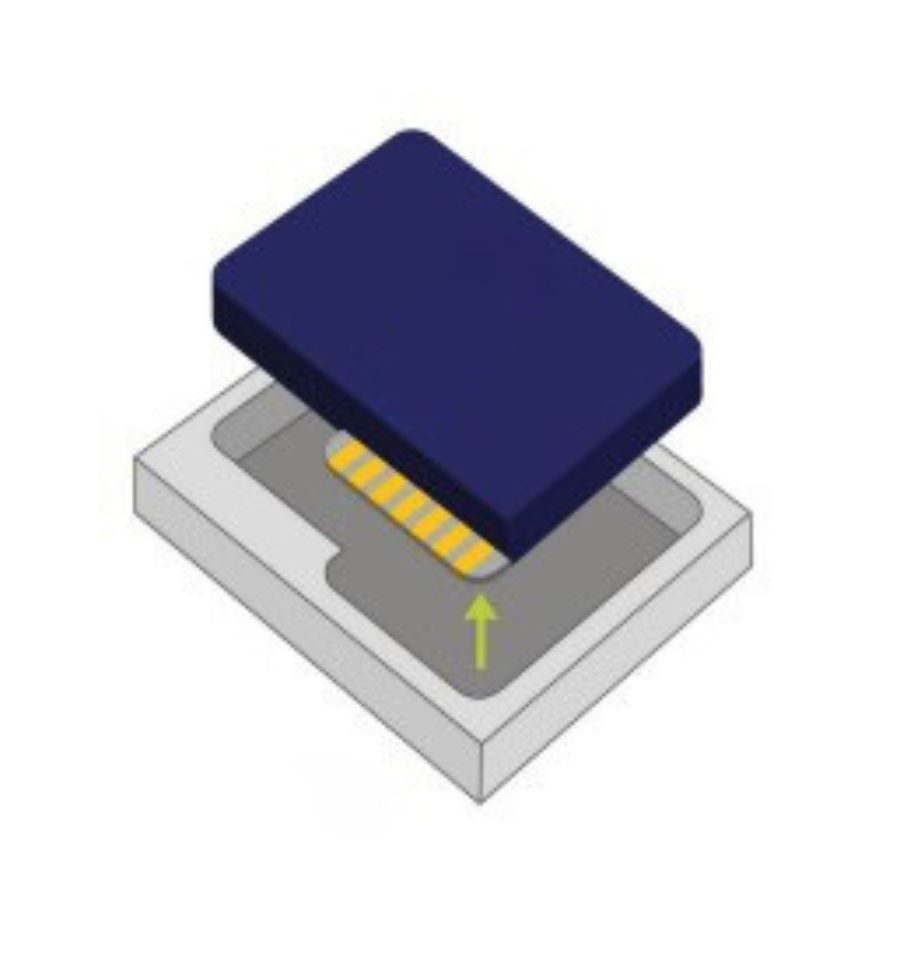

The Low-Pressure Molding Process (LPM) works by placing delicate electronic components like circuit boards and wires into a custom mold. Then, melted resin plastic, like polyamide (hot-melt), fills the cavity in the mold at appropriate low pressure. This resin plastic hardens around the components, creating a sealed and protected final product according to the shape molded, that's ready for use right away for testing.

The raw materials and specialized molding equipment are essential to this procedure. Hot melts, or polyamide polymers based on dimer acid, are utilized as molding compounds. They are thermoplastics, meaning that when heated, the material loses some of its viscosity and can be reshaped; once cooled, the substance hardens to maintain the desired shape. There are two primary ways that these polyamide polymers are not like other thermoplastics:

- Viscosity: Viscosity is normally very low at processing temperatures of 210 °C (410 °F), and about 3,000 centipoises (similar to pancake syrup). Low injection pressure is necessary to inject low-viscosity materials into a hollow. In actuality, injecting the polyamide material is typically done with a basic gear pump. Particularly when over-molding relatively delicate electronic components, low injection pressure is crucial.

- Adhesion: In essence, polyamide materials are hot-melt adhesives with superior performance. A selected substrate is sealed by polyamide's adhesive qualities. Adhesion is of the purely mechanical variety, meaning that no chemical reaction occurs.

The most widely used amorphous thermoplastic polyamides have a broad application temperature range of -55 to 200 °C (-67 to 392 °F) together with a suitable viscosity spectrum. After heating the material to a liquid state (usually between 180 and 240 °C or 356 and 464 °F), it is injected into a mold set that is relatively cold at very low pressure (usually between 3.5 and 35 bars, or 51 and 508 psi). The electronics to be enclosed are gently surrounded by the low-viscosity polyamide substance as it flows into the mold-set cavity. Additionally, it begins to cool as soon as it comes into contact with the electronics and mold-set cavities. A whole molding cycle usually takes 20 to 45 seconds (or ~ 90 seconds), however, a mold-set cavity can be filled in a matter of seconds. The polyamide material begins to contract as it cools down. Consequently, even after the cavity has filled completely, the injection pressure is continuously delivered. By doing this, the shrinkage that normally happens when the polyamide material transitions from a liquid to a solid—that is, from hot to cold—is offset. The solder does not remelt or flow since the polyamide temperature is not too high for the electronics. This is merely because the heat will be absorbed by the relatively cold mold set, which will lower the possible temperature that a circuit board may encounter. Over-molding circuit boards into millions of pieces is accomplished safely and without incident. A weak solder connection is not stressed by low injection pressure.

Thinking about replacing a process?

LPM: A Streamlined Approach for Encapsulating Electronics

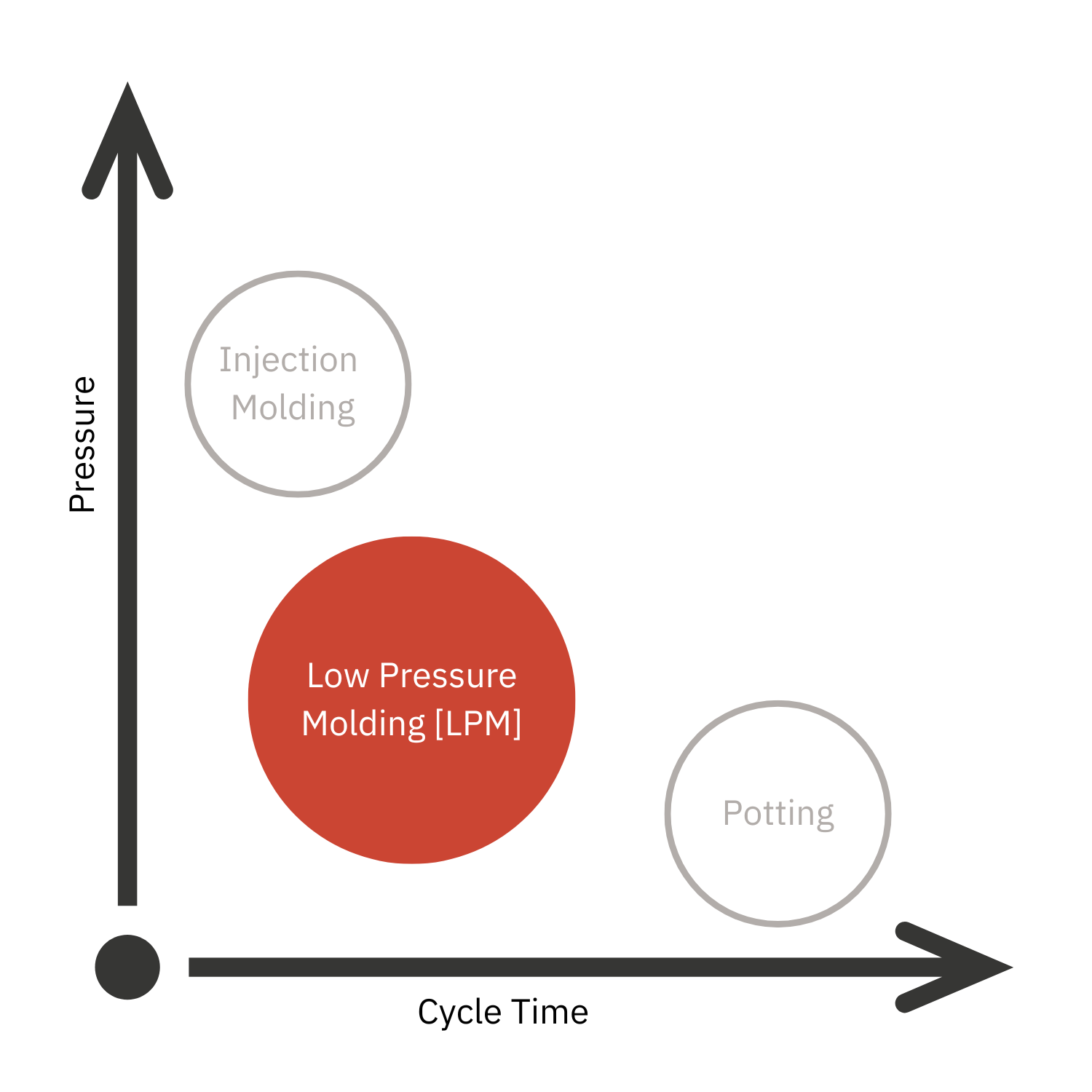

LPM is an innovative manufacturing process that sits between conventional injection molding and the traditional potting processes.

Compared to conventional injection molding, LPM uses less heat and pressure. By using a kinder approach, damage from excessive heat and pressure is avoided on delicate components like circuit boards.

Potting requires seven to eight steps, whereas LPM just requires three. This results in speedier turnaround times for production and faster delivery of your final product.