Thermal putty pads

Thermally Conductive Putty Pads provide high thermal performance and solid thermal reliability. The material’s putty-like consistency enables excellent gap-filling capability for applications with large dimensional variances.

Special surface reinforcement enables easier handling for operators, with no pull-out during high-volume assembly. The product is naturally tacky and requires no additional adhesive to mate to the heat source and heat sink. Putty pads combine ultra soft - high compressibility with a low surface impedance that is complemented by natural tackiness and ease of application.

Typical applications for putty pads can be found in EV battery & charging stations, automotive electronics, power devices & modules, telecommunications & network servers.

Thermal putty pads are available in thicknesses ranging from 0.5mm to 5.0mm.

TGP 3510PT | Thermal Putty Pad

- 0.45 Thermal Impedance

- 3.5 Thermal Conductivity

- 0.5 - 5 mm Thickness

- In stock

TGP 6000PT | Thermal Putty Pad

- 0.27 Thermal Impedance

- 6.0 Thermal Conductivity

- 0.5 - 5 mm Thickness

- 8 weeks

TGP 8000PT | Thermal Putty Pad

- 0.19 Thermal Impedance

- 8.0 Thermal Conductivity

- 0.5 - 5 mm Thickness

- 8 weeks

Product Selector Guide

| Product name | Color | Thickness (mm)1 | Hardness (Shore00) | Specific Gravity | Thermal Conductivity (W/m·K) | Thermal Impedance(˚C·in2/W)(1mm@10psi) | Dielectric Constant @1MHz | Volume Resistivity (ohm·cm) | Flammability Rating |

|---|---|---|---|---|---|---|---|---|---|

| TGP 3500PT | Green | 0.5-5 | 5 | 3.2 | 3.5 | 0.45 | 6.4 | 4.0 x 1013 | V-0 |

| TGP 3510PT | Green | 0.5-5 | 5 | 3.2 | 3.5 | 0.45 | 6.4 | 4.0 x 1013 | V-0 |

| TGP 6000PT | Grey | 0.5-5 | 5 | 3.4 | 6.0 | 0.27 | 6.5 | 4.0 x 1015 | V-0 |

| TGP 8000PT | Grey | 0.5-5 | 5 | 3.5 | 8.0 | 0.19 | 8.5 | 4.0 x 1015 | V-0 |

Frequently Asked Questions

What are the benefits of Thermal putty pads?

The material’s putty like design makes it ultra soft and compressible and enables excellent gap filling capability for applications with large dimensional variances. Special surface reinforcement enables easier handling for operators during high volume assembly.

The hardness is completely different compared to gap pads. Putties are soft and require little to no pressure, something that makes them good replacements for thermal gels. They are non electrically conductive and come in large form factors they work great if properly handled.

Additionally, they are naturally tacky and require no additional adhesive to mate the heat source and heat sink.

Learn More

Thermal Putty Pads

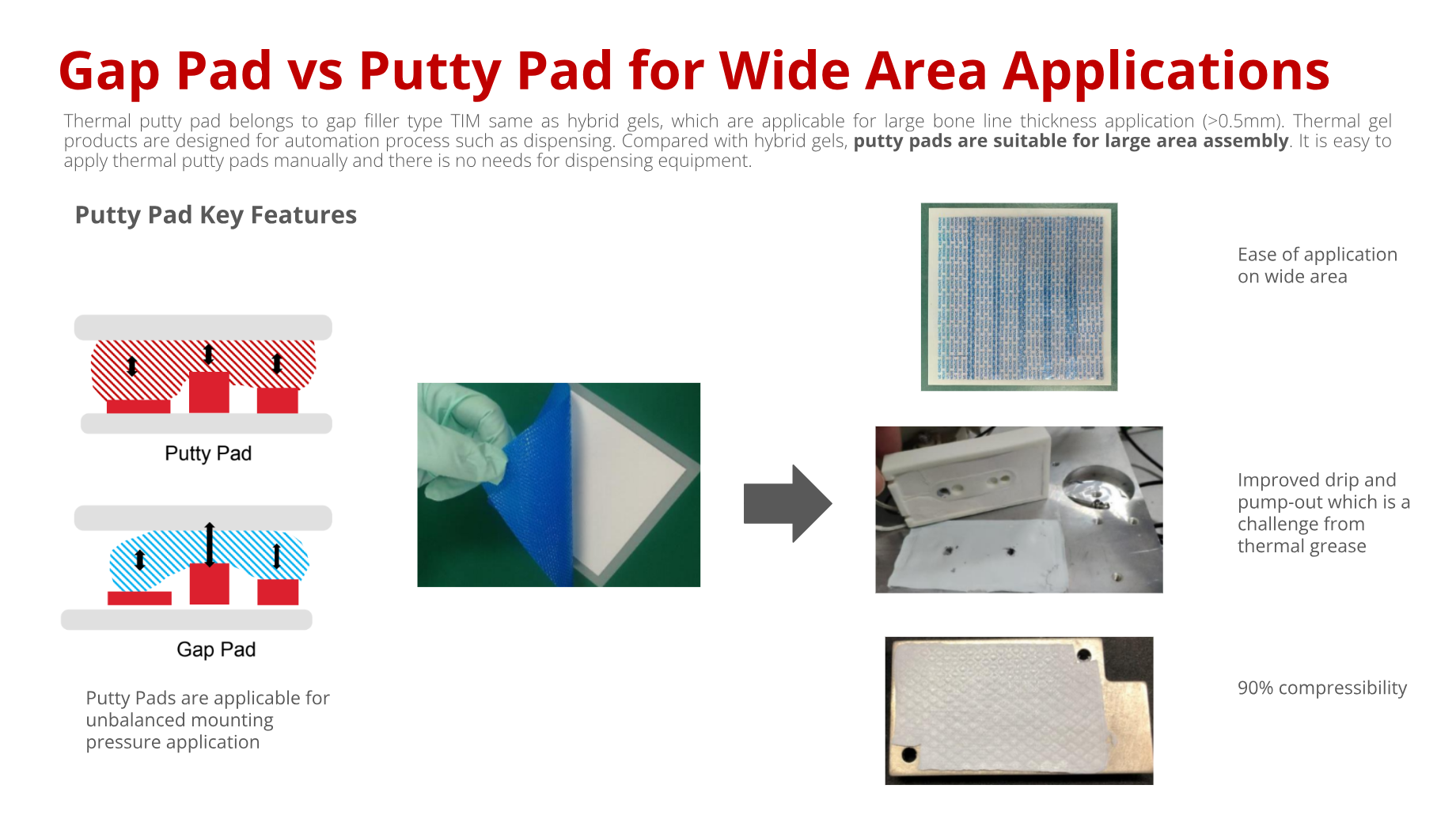

Thermal Putty Pads V.S. Thermal Gap Pad

.png) | .png) |

Putty pads don't have tensile strength and elasticity

- Putty pads require a minimum amount of compression; at least 10%. They are soft, and eventually they will bottom out past 80%.

- They also relax over time. what’s referred to as densification. The material is no longer flowing and is being crushed. Make sure not to exceed a certain amount of force when using these materials.

Putty pads are ultra-soft

Thermal putty pads and thermal gap pad are similar products. For example, TGP8000 and TGP8000PT both have high thermal conductivity as 8 W/m.K and need at least 10% compression while applying. The main difference is that thermal putty pads are ultra-soft and could be compressed up to 90%. It almost has no tensile strength and no elasticity, thus will not recover and bounce back. Due to the low stress and high compressibility, thermal putty pads are more suitable for applications with large dimensional variances, comparing with traditional thermal gap pad.Difference with thermal gels

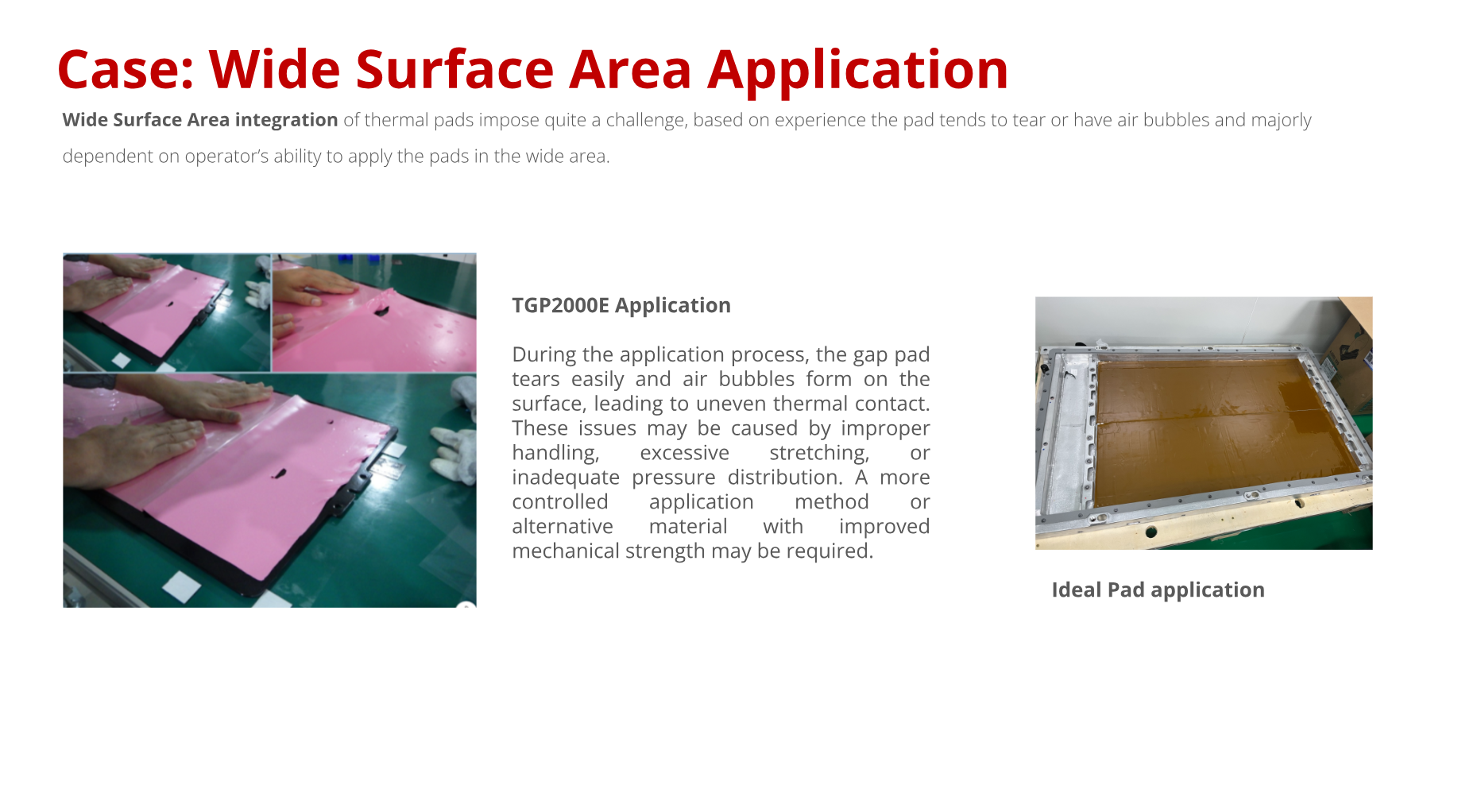

Both thermal putty pad and thermal hybrid gel belong to gap filler type TIM, which are applicable for large bond line thickness application (>0.5mm). Thermal gel products are designed for automation process such as dispensing. Compared with hybrid gels, putty pads are suitable for large area assembly. It is easy to apply thermal putty pads manually and there is no need for dispensing equipment.