TGP 8000PT | Thermal Putty Pad

- 0.19 Thermal Impedance

- 8.0 Thermal Conductivity

- 0.5 - 5 mm Thickness

Product Description

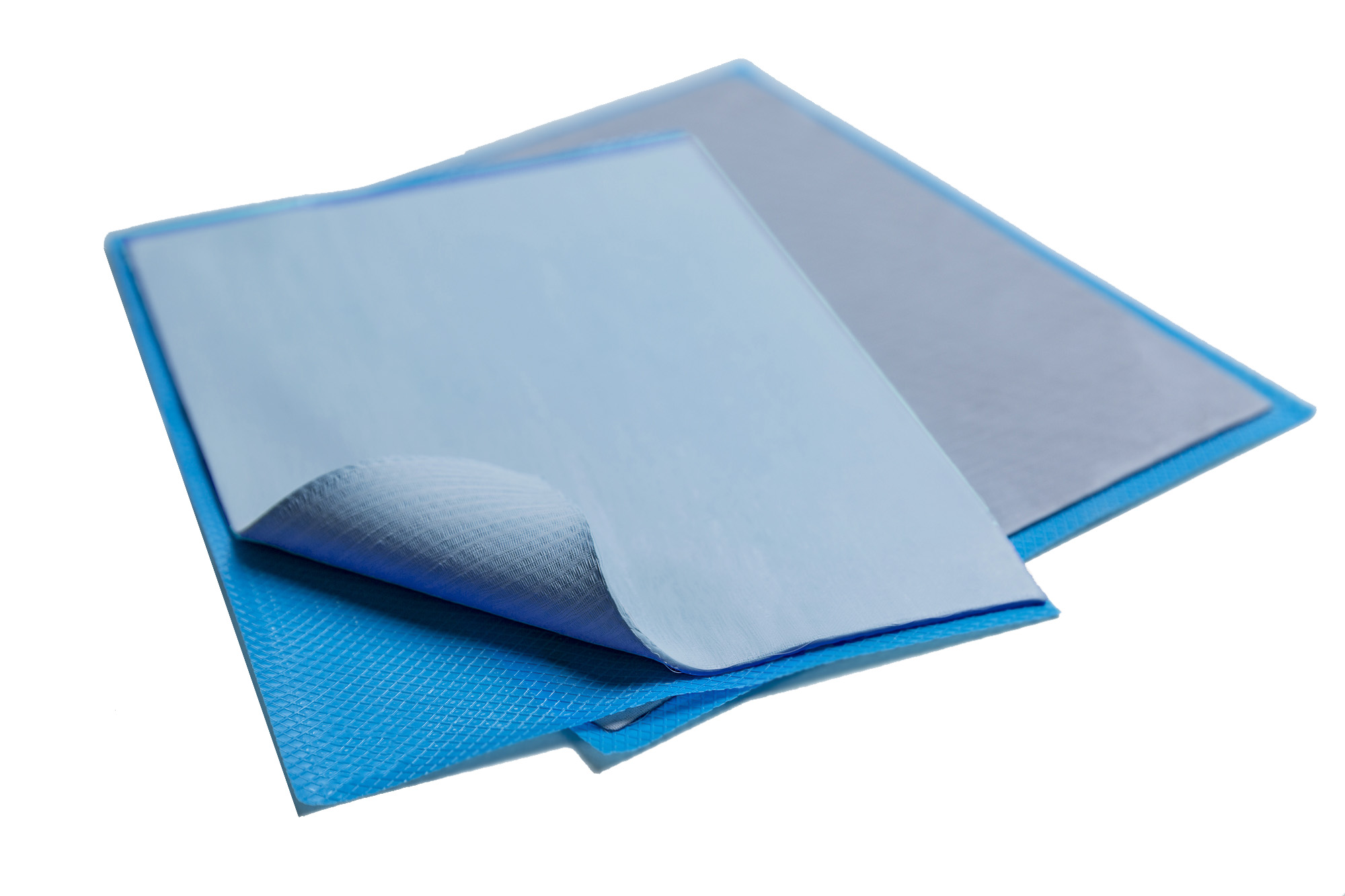

Honeywell TGP 8000PT Thermally Conductive Putty Pads provide high thermal performance and excellent thermal reliability (8 W/mK). The material’s putty-like design enables excellent gap-filling capability for applications with large dimensional variances within surfaces. Special surface reinforcement enables easier handling for operators during high volume assembly. Pads thicker than 0.5mm come contained and reinforced within single sided fiber glass and dual liners.

Honeywell TGP 8000PT is naturally tacky and requires no additional adhesive to mate to heat source and heat sink. This product can be used for unbalanced mounting pressure applications while also improving dripping and pump out, compared to thermal grease. It is available in thicknesses ranging from 1.0mm to 5.0mm. With 10~70% compression, the final BLT could reach a minimum of 0.5mm.

Learn more When should you choose thermal putty pad over thermal gap pad and thermal gel.

Available Versions:

- TGP8000PT-01, single-side fiberglass reinforced version; (increased tackiness to the heatsink surface and recommended for small size application)

- TGP8000PT-00, no fiberglass reinforced version

- Properties customization possible (compression-deflection, breakdown voltage)

- Die-cut shapes possible

Key Features:

- Low thermal impedance and UL94 V-0 listed

- BLT (bond line thickness) from 1mm to 5mm

- Natural tacky to the heatsink and heat source

- Ultra-soft (shore00, 5) with high compressibility and low stress generated

- Suitable for applications with large dimensional variances

- Minimum bleeding and pump out controlled

Highly Recommend For:

- Automotive/consumer electronics, PCB

- Power device & modules

- Telecommunications & network servers

- Semiconductors logics & memory

- EV battery & charging station

Technical Specifications

| General Properties | |

| Color Color The color | Gray |

| Film Thickness Film Thickness Film thickness is the thickness of a backing film without taking into account any coatings or adhesive layers. It is measured in micron and the conversion factor to mil is 0.039. | 1 - 5 mm |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 3.5 |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 8.0 W/m.K |

| Thermal Impedance | 0.19 °C·cm²/W |

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V-0 |

| Electrical Properties | |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 4.0x1015 Ohms⋅cm |

Additional Information

Thermal putty pad VS. thermal gap pad

Thermal putty pads and thermal gap pad are similar products. For example, TGP8000 and TGP8000PT both have high thermal conductivity as 8 W/m.K and need at least 10% compression while applying. The main difference is that thermal putty pads are ultra-soft and could be compressed up to 90%. It almost has no tensile strength and no elasticity, thus will not recover and bounce back. Due to the low stress and high compressibility, thermal putty pads are more suitable for applications with large dimensional variances, comparing with traditional thermal gap pad.

Thermal putty pad VS. thermal hybrid gel

Both thermal putty pad and thermal hybrid gel belongs to gap filler type TIM, which are applicable for large bone line thickness application (>0.5mm). Thermal gel products are designed for automation process such as dispensing. Compared with hybrid gels, putty pads are suitable for large area assembly. It is easy to apply thermal putty pads manually and there is no needs for dispensing equipment.

TGP8000PT Thermal Performance

Shelf Life: 12 months at 23±2˚C

Thickness range: 1.0-5.0mm with 0.25mm incremental

Thickness Tolerance: >=1mm, ±10%, 0.5-1mm, ±0.1mm