Mold Release Sprays

Mold Release Sprays are an essential accessory in all varieties of thermoplastic and thermoset molding processes, but it's equally essential that one understands what the right applications are for carnauba wax and other aerosol sprays as they are so undervalued and misunderstood. Mold Release Spray can do more than clean stuck plungers. They are an essential surface treatment before testing any new molding compounds, breaking in new mold tools, and when returning mold plates to service after a clean or maintenance.

Epoxy molding compounds and other thermoset plastics require a mold release agent to release from the mold after curing. Mold release sprays offered by CAPLINQ offer both mold release properties as well as compatibility with the epoxies and other thermoplastics they are using.

MJ Gordon, the leading supplier of epoxy mold release sprays has stopped supplying their lead product #909C. Since MJ Gordon series have become unavailable due to environmental concerns, CAPLINQ has developed a series of alternatives that have been tested and proven for the same applications for which MJ Gordon was used.

Permasil 909C | Carnauba Wax Mold Release Spray

- Carnauba wax Mold Release Spray

- Solvent-based, non-flammable

- Compatible with Epoxy Mold Compound

- No longer available

CHEMLINQ MRE-C909 | Carnauba Wax Mold Release Spray

- Alternative to MJ Gordon #909C

- Carnauba wax mold release Spray

- Compatible with Epoxy Mold Compound

- In stock

Chemlinq MRE-S101 | Silicone Mold Release Spray

- Silicone based Mold Release spray

- Green label

- Compatible with Epoxy Mold Compound

- 8 weeks

Product Selector Guide

Selecting the Right Mold Release Agent for Thermosets and Thermoplastics

Thermoset and thermoplastic molding production lines come in all shapes and sizes, and are an essential process across a number of industries, manufacturers, and for a number of diverse applications: semiconductor, automotive, and electronics, to name a few. Depending on the mold and the type of plastic you are molding, you have a choice between carnauba wax, silicone , PTFE (Teflon) and others as mold release agents.

| Product Name | Technical Specifications | Comments | |||

|---|---|---|---|---|---|

| Release Base | Solvent Base | REACH Compliant | RoHS Compliant | ||

| MJ Gordon #909C | Carnauba Wax | Non-Flammable Solvent |  |  | Used to be industry standard mold release No longer RoHS/REACH Compliant |

| Chemlinq MRE C909 | Carnauba Wax | Flammable Solvent |  |  | Direct Alternative to MJ Gordon #909C Carnauba wax for epoxy molding compound mold release |

| LinqSil S-100 | Silicone | Flammable Solvent |  |  | Suitable for most epoxy molding compounds, hot- and cold-cured epoxy, polyurethane and polyester resins. (discontinued) |

| Chemlinq MRE-S101 | Silicone | Flammable Solvent |  |  | Suitable for most epoxy molding compounds, hot- and cold-cured epoxy, polyurethane and polyester resins. |

Frequently Asked Questions

Frequently asked questions about Mold release sprays

How can I dispose of Aerosol cans? The SDS says "Do not pierce or burn even after use"

The main risk is that the can can (heh) potentially explode if there is still propellant inside.

Proper disposal can be achieved with a system similar to "Aerosolv Recycling Systems" which is something commonly used by recycling companies. Our suggestion is to use a waste disposal company that collects aerosol cans but it is up to you whether you want to take the risks of doing this in-house.

If you decide to do it in-house make sure that you use a non sparking pin and that the can is completely empty without solvent, product, or propellant left inside.

It is safer to perform all these procedures in a well ventilated area with good air flow and without any electric sparks or naked flames anywhere in the vicinity.

MJ Gordon is unreachable. What can I do?

This is not a surprise for anyone that was keeping a close eye in the carnauba wax supply chain. A lot of our customers were fully dependent on a steady supply of mold release. Something that was unfortunately not happening.

That\'s why we were a few steps ahead and we were slowly but surely perfecting our own mold release spray formulation.

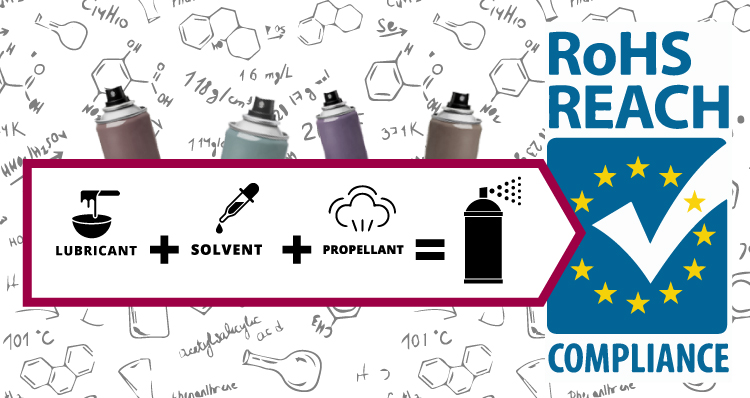

After a LOT of tries, we came up with Chemlinq MRE-C909. A direct alternative to MJGordon Permasil #909C. It is a fully REACH and RoHS compliant carnauba wax mold release aerosol spray and does not contain trichloroethane (CAS: 71-55-6) or dichloromethane (CAS: 75-09-02). MRE-C909 is literally the 9th iteration, and serves as a reminder of the 8 previous unsuccessful formulation attempts before finally formulating MRE-C909.

Learn More

Mold Release Sprays are Everywhere

One essential, but misunderstood, product can be found across all varieties of plastic molding lines and present across all varieties of their production floors: the Mold Release Spray. It seems odd that this should be the case since no production line engineer or technician actually wants to have to use mold release spray. Being manually applied they require man power, and are for the same reason inconsistent: likely to be sprayed too much or too little.

In an ideal molding production process you don’t need mold release spray. The molded part releases easily, the mold die plate never accumulates a build-up of residues, and the molding machine works smoothly and efficiently time after time.

In reality, however, that is never case. Molded parts are hard to release from the cavity, stains and residues build up and so require cleaning, and sometimes plungers get stuck and require cleaning. Even though we would rather not have these problems, we do: so it’s a simple case of problem-solution. That’s why good Mold Release Spray is an indispensable multi-purpose problem-busting solution.

Mold Release Sprays are Essential

Mold Release Sprays are an essential accessory in all varieties of thermoplastic and thermoset molding processes, but it\'s equally essential that one understands what the right applications are for carnauba wax and other aerosol sprays as they are so undervalued and misunderstood. Mold Release Spray can do more than clean stuck plungers. They are an essential surface treatment before testing any new molding compounds, breaking in new mold tools, and when returning mold plates to service after a clean or maintenance.

Moving beyond solutions to exceptional problems they are an integral part of a regular production procedure. Mold Release Sprays extend the lifespan of the mold and give the demolded parts a beautifully finished surface.

For very thin, flexible, or very sensitive parts, Mold release spray is essential in making sure the parts do not rip or tear in the demolding process. By making demolding and releasing the part from the mold cavity easier and faster they increase productivity. They further increase productivity by reducing scrap and defect rates.

MJ Gordon #909C Industry Standard Mold Release Spray

MJ Gordon’s green #909C was the industry standard mold release spray for the last 30 years with a 90% share of the mold release spray market.

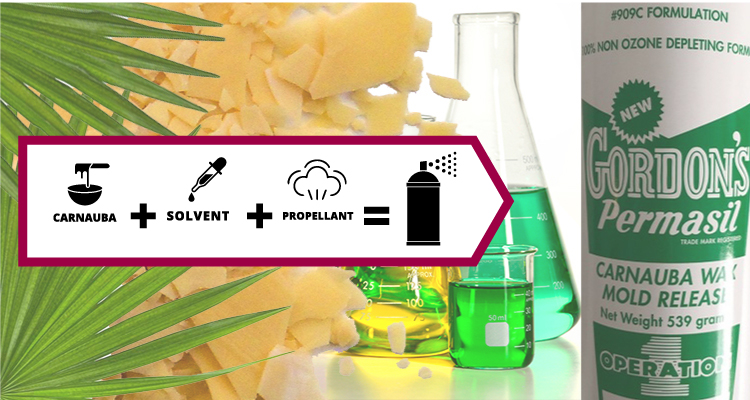

At the time a revolutionary product, it transformed long lasting carnauba hard wax into an easily sprayable solution by dissolving it in a water-based solvent. This meant it could dry faster, and continue to provide release longer than most other brands.

As such, the MJ Gordon #909C is a solvent-based, non-flammable carnauba wax spray was loved by engineers and line operators alike for more than four decades.

Carnauba Wax and Gordon\'s #909C Mold Release Spray

Of all the mold release agents, Carnauba wax is the most used in thermoset and thermoplastic mold production lines. The main reason carnauba wax is so pervasive is because it is so compatible with epoxies and other thermoset plastics.

Epoxies love carnauba wax

Not only are epoxies incredibly compatible with epoxy; in many cases, the use of carnauba wax actually enhances main properties of the epoxy itself. In fact, epoxy mold compound formulators rely on carnauba wax as an internal mold release when formulating epoxy molding compounds, using as much as 0.5% or more by weight in its formulation.

As such, it is no wonder that when it comes to choosing a mold release spray for external applications it’s one of the most suitable for thermoset and thermoplastic molding production lines.

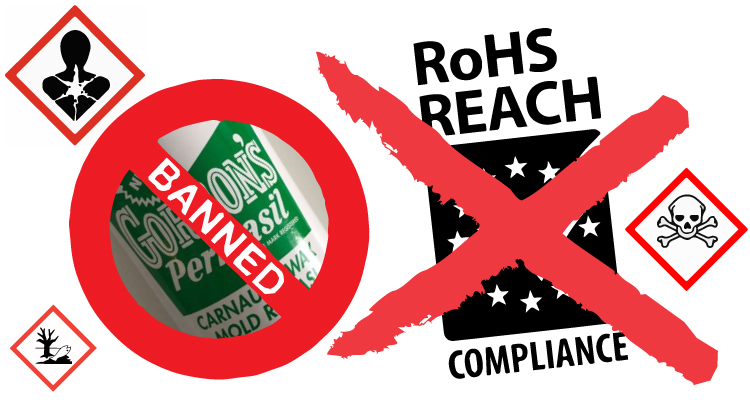

The good and bad news about MJ Gordon #909C

Unfortunately its best property is also its worst property. MJ Gordon\'s 909C uses a non-flammable propellant which makes it much safer to use in high-temperature industrial settings while still being fast-drying. However, that propellant: n-Propyl Bromide isn’t REACH or RoHS compliant.

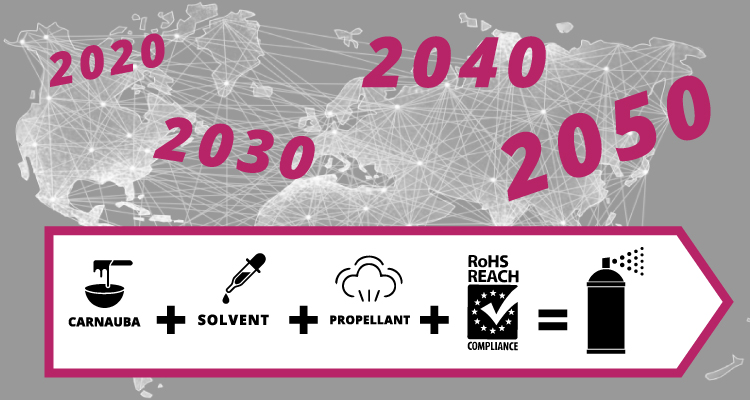

REACH and RoHS are here to stay

This makes it a less attractive option for goods or manufacturers that are molding their products in the EU. Going into the future, REACH and RoHS are predicted to become global industry standards, so it seems MJ Gordon’s is a sinking ship.

MJ Gordon\'s #909C Alternative Mold Release Sprays

Finding a non-flammable mold release spray to replace MJ Gordon’s #909C is the holy grail of production lines that need to be REACH or RoHS compliant. However, it\'s by no means an easy task. Most alternatives are typically silicone or PTFE (Teflon) based sprays, and so are not compatible with epoxy molding compounds. Because their base chemistry is incompatible they would lead to mold fouling and contamination – causing product delamination and other defects. That’s why manufacturers often look towards semi-permanent mold release agents applied as a mold-conditioning product that eliminates the inconsistencies of manual applications.

CAPLINQ has invested a lot of time and resources to develop alternative mold release sprays. To complement our range of epoxy molding compounds, and as part of our CHEMLINQ product family, CAPLINQ developed two mold release sprays with great properties. Unlike MJ Gordon’s 909C these are REACH and RoHS compliant, and highly compatible with a diverse range of thermosets and thermoplastics.

Epoxidized Silicone Mold Release Spray

Our years of R&D to find a REACH and RoHS compliant carnauba wax mold release alternative led us to an industry disrupting break-through: epoxidized silicone mold release spray. This special formulation of epoxy and polyether modified dimethylsiloxane has open-chains, like little fingers, that bond very well with epoxies. This insight became clear to us after we reconized that the Epoxidized Silicone Dow Corning Toray SF-8421-EG Fluid was also an epoxidized silicone. CAPLINQ suppplies this material to epoxy mold compound manufacturers who use this as the internal release agent for their own brands of epoxy molding compounds.

This means that, unlike normal silicones which are chemically incompatible with epoxies and silicones, it has incredibly high compatibility with silicones and epoxies. It’s also cheaper than carnauba wax mold release sprays, coming in at a fraction of MJ Gordon’s 909C’s price.

Our LinqSil™ Mold release spray series, is fully compatible with thermoplastics including epoxy, epoxy mold compounds, polyurethane, polyester resins, EPDM, nitrile, and flexible or rigid integral foam products. Because of its high compatibility, high release performance, and high-temperature resistance (successful in applications running as hot as 200°C), it is fast becoming the industry standard mold release for the semiconductor device industry.