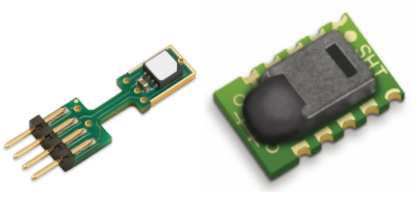

Humidity and Temperature sensors

High reliability sensors require molding compounds with good adhesion and reduced moisture uptake in order to increase their MSL performance. Catalytic to this point is the high filler loading that enables a lower moisture uptake.

Application considerations

- Used in variety of applications including mobile devices

- Passing 160°C high temperature operating test

- Passing MSL1 & 1000 TC customer reliability

- Best adhesion on PPF lead frame

- Compatible with cavity and film assisted molding process

Molding compound solutions for humidity and temperature sensors

Property / Product | Unit | Hysol | Hysol |

UNCURED PROPERTIES |

| ||

Hot Plate Gel time, @ 175°C | s | 32 | 40 |

Spiral Flow @ 175°C | in | 60 | 67 |

Flammability |

| V-0 | V-0 |

Halogen-free (Green) | ✔ | ✔ | |

Shelf Life @ 5°C | months | 12 | 12 |

TYPICAL CURED PROPERTIES |

| ||

Specific Gravity, g/cc | g/cc | 1.95 | 1.95 |

Glass Transition Temperature | °C | 170 | 184 |

Coefficient of Thermal Expansion (CTE) |

| 11 | 11 40 |

Flexural Strength, @25°C | MPa | 137 | 119 |

Flexural Strength, @240°C | MPa | 19.6 | 19.6 |

Flexural Modulus (E), @25°C | GPa | 20.6 | 20.6 |

Flexural Modulus (E), @220°C | GPa | 2.26 | 2.26 |

Moisture Absorption, 24hr PCT | % | 0.27 | - |

Mold Shrinkage, as molded | % | 0.10 | 0.15 |

Thermal Conductivity | W/mK | 0.9 | - |

Summary |

| ||