Low voltage

Low voltage busbars are used primary in switchgear equipment for residential or industrial use. The switchgear equipment may contain single busbar or double busbars, and the types of switchgear may be solid-, air-, or gas-insulated. In all cases, the rated voltage of low voltage switchgear does not exceed 690 Vac. Though this is high voltage compared to the outlets in your house, these are still quite low voltages compared to the 12kV to 38kV used in medium voltage busbar applications. In these case, the thickness of the epoxy coating used is much, much less than for medium voltage busbars. The purpose of the epoxy coating powder is the same however: to insulate the busbars from each other and to prevent dangerous arcing faults.

Parameters considered for epoxy coating powders for low voltage busbars include:

- Can the epoxy coating powder be applied in a thin enough layer in order to optimize the cost/performance of low voltage applications?

- Can the epoxy coating powder be used in an outdoor environment or for outdoor applications?

- Can the epoxy coating powder be made to be flexible to maximum design efficiency and to bend the busbars after coating?

For many years, CAPLINQ has supplied a range of epoxy coating powders developed for low voltage (up to 690V) busbar and switchgear equipment. CAPLINQ is one of the few epoxy coating powder suppliers qualified for use in Power Distribution Switch Boards and also electric vehicle charging stations. Given the critical nature of the application, the time and costs involved to pass UL-certification, major Power Management Companies rely on CAPLINQ and their family of UL-capable epoxy coating powders. All the products offered by CAPLINQ for busbar applications are UL capable and can be subject to test upon agreement with the end customer.

Three products stand out in the CAPLINQ product line for low voltage busbar applications.LINQSOL BCP-1000, LINQSOL BCP-1504 and LINQSOL BCP-1507. These are all close alternatives to the legacy products DK15-0606, DK15-0907, DK15-0463 DK15-2000E.

The "One Powder Solution": LINQSOL BCP-1507

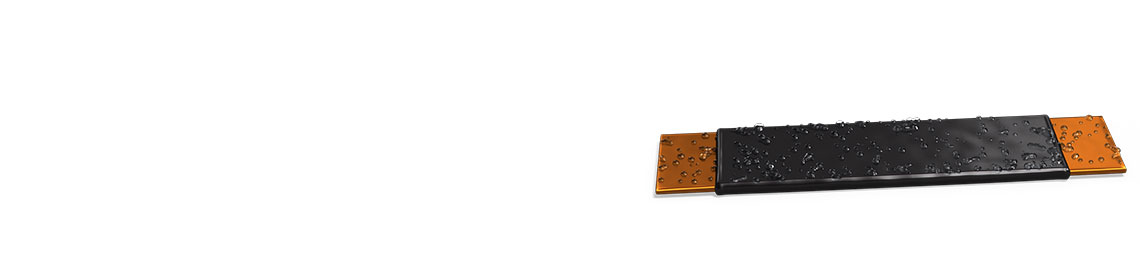

LINQSOL BCP-1507 is a one powder solution available in orange, red, black, blue, and green. It is especially suitable for EV busbars and small busbars applications. The low heat capacity of small busbars limit the dipping times, thus it requires coating powders low pick-up temperature and high build rate, which BCP-1507 aims at. BCP-1507 meets the UL 746B Relative Thermal Index (RTI) of 130°C and CTI 600V.

- Comparable with DK15-0606/DK15-0907

- Good adhesion to copper, alumina

- Good flowability and low viscosity while melting

- Low pick up temperature

- High powder build rate (able to reach 0.5mm with 1 dip)

- Both electrostatic spray and fluidized bed coating

Cost effective environmental resistance with LINQSOL BCP-1000

If you are only making low voltage busbars with electrostatic spraying, nothing beats the value for money you can get from LINQSOL BCP-1000. This low voltage epoxy powder is widely applied in various low voltage busbar applications (<600V) as an insulation and moisture-proof protective layer. This busbar insulation epoxy powder allows high production efficiency thanks to its fast curing characteristics. It is strongly recommended for electrostatic spraying (60-80KV) coating. It offer the best cost-performance ratio.

LINQSOL BCP-1504 offers Process Flexibility

LINQSOL BCP-1504 applies at low voltage copper and alumina busbars (600V) with a coating thickness of 0.3~1mm. This epoxy powder brings high productivity with low pre-heat temperature and quick curing. Due to its fine-grind process, it can be used with both electrostatic spray and fluidized bed dipping.

The industry standard for busbar coatings, with beds holding up to 3,000kg of powder at a time.

The electrostatically sprayed powder can adhere to a wide area from a single spray direction.

Low voltage Busbar Coating powders Selector Guide

| BCP-1000 | BCP-1504 | BCP-1507 | |

| Particle size | >320 mesh, 20.5% 180-230 mesh, 74% 100-180 mesh, 5.5% <100 mesh, 0% | >400 mesh, 15~30% 140-400 mesh, 44~73% 100-140 mesh, 10~20% <100 mesh, 2~6% | >320 mesh, 10% <80 mesh, 0% |

| Specific Gravity, g/cc | 1.45±0.05 | 1.52±0.05 | 1.50 |

| Glass Plate Flow | 18-22mm@150°C, 45° | 10-22mm@150°C, 60° | 19-20 mm@180°C |

| Hot Plate Gel Time | 70 sec@150°C | 45±15 sec@160°C | 60 sec@180°C |

| Edge Coverage, % | 45 | 45 | 45 |

| Hardness, shore D | >80 | >90 | - |

| Impact Resistance, cm | >50 | >50 | >50 |

| Dielectric Strength (kV/mm) | >42 | >35 | >35 |

| Flammability, UL94 | V-0 | V-0 | V-0 |

| Min. Coating Thickness | 0.3mm | 0.3mm | 0.1mm |

| Max. Coating Thickness | 1mm | 1mm | 2mm |

| Electrostatic Spray | ■■■ | ■■□ | ■■■ |

| Dip Coating | ■□□ | ■■■ | ■■■ |

| Available Color | ●●●●● | ●● | ●●●●● |

| Preheat Temperature | 180~240 °C | 150~180 °C | 180~230 °C |

| Curing Conditions | 200°C x 15min | 200°C x 15min | 200°C x 30min |