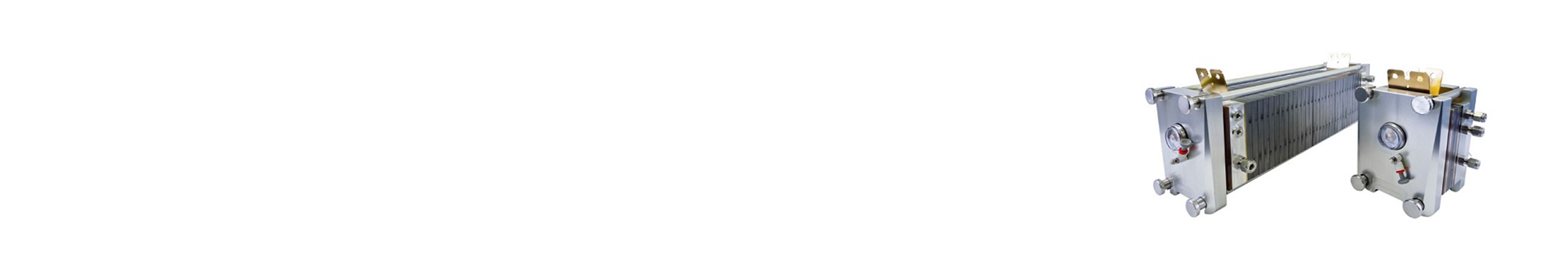

Porous Transport Layers for Water Electrolyzers

Porous transport layers are equivalent to gas diffusion layers of fuel cells. They facilitate the movement of the output gases, such as hydrogen and oxygen, while ensuring efficient and uniform distribution of the feed material (water) within the cell. These layers play a crucial role in enhancing overall water electrolyzer performance by optimizing reactant delivery and product expulsion, and promoting efficient electrochemical reactions.

Cathodic Porous Transport Layers

At the cathode side, carbon-based materials are the predominantly used porous transport layer owing to the stability of carbon under reducing conditions. enerally, thin (<1mm) sheets are used for fuel cell GDLs, while thicker panels (1.5–3.0 mm) are used for electrolyzers. While CAPLINQ can custom-make specific thicknesses, these are what our customer most often ask us for.

| Product | Thickness | Thickness (mm) | Density (g/cm3) | Basis weight (g/m2) | Through-Plane Resistance (mΩcm2) | Through-Plane Resistivity (mΩcm) | Voltage Loss (mV) |

|---|---|---|---|---|---|---|---|

| LINQCELL GDL 1500 | 0.059" | 1.5 | 0.60 | 858 | 13.32 | 90.6 | 24.3 |

| LINQCELL GDL 1500B | 0.059" | 1.5 | 0.60 | 670 | 21 | 140 | 39 |

| LINQCELL GDL 1850 | 0.072" | 1.85 | 0.85 | 1562 | 13.18 | 70.5 | 25.5 |

| LINQCELL GDL 2200 | 0.086" | 2.2 | 0.6 | 1550 | 17 | 110 | 35 |

| LINQCELL GDL 2900 | 0.011" | 2.9 | 0.60 | 1734 | 24.57 | 87.7 | 27.6 |

All values are indicative and subject to tolerance

Anodic Porous Transport Layers

At the oxygen (anode) side of water elctrolyzers, the environment is much more corrosive because of usage of pure oxygen and application of potentials as high as 2 V. The highly oxidative environment at the anode corrodes the carbon-based LGDLs, thereby forming CO2 (Eqn. 1) and carbonate ions (Eqn. 2) in acidic and basic media, respectively. Carbon corrosion drastically reduces the the activity and stability of the anode during galvanic or electrolytic operations. For these reasons, metal-based PTLs, more commonly titanium and nickel-based GDLs, are used at the anode of and water electrolyzers.

Titanium as Anodic PTLs

Titanium fiber papers exhibit strong corrosion resistance in PEM water electrolyzers. They form a protective passivation layer that prevents direct contact with corrosive electrolytes, stabilizes the surface, and reduces defect-related corrosive reactions, improving device performance and durability.

LINQCELLTM Titanium Fiber Paper Properties

Product | Porosity (%) | Thickness (um)* | Basis Weight (g) | Actual weight (g)** |

50–60 | 250 | 45.5 | 18.3–22.6 | |

60–70 | 250 | 45.5 | 13.7–18.1 | |

50–60 | 400 | 72.8 | 29–36.3 | |

60–70 | 400 | 72.8 | 22–29 | |

50–60 | 600 | 109.3 | 44–54.5 | |

60–70 | 600 | 109.3 | 32.8–43.6 | |

50–60 | 800 | 145.7 | 58.3–72.9 | |

60–70 | 800 | 145.7 | 43.7–58.2 |

Nickel as Anodic PTLs

Nickel fiber paper is also a valuable PTL in water electrolyzers and fuel cells, facilitating reactant transport and product gas removal while maintaining strong electrical conductivity. It serves as a cost-effective alternative to titanium fiber papers. Nickel fiber paper's durability and affordability make it a practical choice for PTL applications, particularly when stable electrical performance and cost efficiency are paramount.

Property | Titanium | Nickel |

Electrical Conductivity | Moderate, lower than Nickel | High, excellent electrical conductor |

Corrosion Resistance | Excellent, highly corrosion-resistant | Good, less corrosion-resistant than Titanium |

Cost | Expensive | Affordable, cost-effective |

Oxidation Under High pH | Resistant | Susceptible, can oxidize in alkaline conditions |

Weight | Lightweight | Lightweight |

Mechanical Strength | High, strong | Good strength |

Thermal Conductivity | Moderate | High, excellent thermal conductor |

Application Suitability | Most suitable for high-pH environments, such as alkaline fuel cells | Versatile, can be used in a wide range of environments, but may perform better in moderate pH values |

It is important to consider specific application requirements, as the choice between Titanium and Nickel as a porous transport layers will depend on factors such as pH conditions, cost constraints, electrical and thermal performance, and material availability.

LINQCELLTM Nickel Fiber Paper Properties

Product | Porosity (%) | Thickness (um) | Elongation (%) | Tensile Strength (MPa) |

40–90 | 250 | ≥8 | 5–8 | |

50–90 | 500 | ≥8 | 5–8 |

Stainless Steel as Versatile Anode and Cathode PTL

Discover CAPLINQ's stainless steel fiber felts—an innovative solution for fuel cells and electrolyzers, excelling in both anode and cathode applications. Engineered with highly catalytic alloy components (Ni, Co, Fe, Mo, and Mn), these felts optimize oxygen evolution reactions at the anode while showcasing exceptional durability and resistance to hydrogen embrittlement at the cathode.

CAPLINQ's stainless steel fiber felts come in three thicknesses– 250 (LINQCELL SFP 250), 600 (LINQCELL SFP 600), and 1000 (LINQCELL SFP 1000) µm, offering adaptability for various applications and providing a reliable and advanced solution to enhance the efficiency and resilience of your systems.

General Property Comparison of LINQCELLTM Cathode Porous Transport Layers

Property | Carbon Cloth or Fabric | Graphitized Carbon Paper | Stainless Steel Fiber Paper |

Electrical Conductivity | ■■■□ Good | ■■■■ High | ■■□□ Moderate |

Corrosion Resistance | ■■■□ Good | ■■■■ High | ■■□□ Moderate |

Compressibility | ■■■□ Good | ■■■■ High | ■■□□ Moderate |

Cost | ■■■□ Cheap | ■□□□ Expensive | ■■■■ Cheapest |

Weight | ■■■■ Lightest | ■■□□ Moderate | ■□□□ Heavy |

Temperature Stability | ■■■■ Excellent | ■■■■ Excellent | ■■□□ Moderate |

General Property Comparison of LINQCELLTM Anode Porous Transport Layers

Property | Titanium | Nickel | Stainless Steel |

Electrical Conductivity | ■■■□ Good | ■■■■ High | ■■□□ Moderate |

Corrosion Resistance | ■■■■ High | ■■□□ Moderate | ■■■□ Good |

Compressibility | ■■□□ Moderate | ■■■□ Good | ■■■■ High |

Cost | ■□□□ Expensive | ■■■■ Cheapest | ■■■□ Cheap |

Weight | ■■■■ Lightest | ■■□□ Moderate | ■□□□ Heavy |

Temperature Stability | ■■■■ Excellent | ■■■□ Good | ■■□□ Moderate |

Availability | ■□□□ Rare | ■■■■ Abundant | ■■□□ Moderate |

Note: The rankings provided are based on general properties and characteristics of carbon, titanium, nickel, and stainless steel. Actual performance may vary based on manufacturing processes, and environmental conditions. These rankings are intended as a broad overview and should not be the sole factor in decision-making. For precise and application-specific information, it is recommended to consult relevant scientific literature, engineering specifications, and industry experts. Additionally, advancements in materials science and technology may influence the properties of these materials over time. The rankings are subject to change based on new developments and research in the field. Contact us for your cathode and anode PTL needs.