Optocoupler

Optocoupler/Photocouplers consist of an infrared LED (emitting device) and a photosensitive receiving device optically coupled into the same package. What this does is allows electrical signals to be passed from the input to the output circuit; separated by an isolation barrier that is designed to withstand high voltage levels. It allows for the isolation of high and low-voltage components reliably. This finds its way into many applications for safety reasons, as well as to prevent the damaging of expensive or important electrical components.

Package:SOP4, SOP5, SOP8, SOP16, DIP4, DIP6, DIP8, etc.

Devices:transistors, IGBT drive gate, TRIAC, etc.

Typical Reliability Tests

- JEDEC MSL3 to MSL1, reflow@260°C

- High-temperature storage: 150°C x 1000hrs

- Temperature cycling: -55~125 °C x 1000 cycles

- uHAST: 168hrs @130°C and 85%RH

- Temperature humidity bias: 1000hrs @85°C, 85%RH, Vcc

Within the optocoupler market, industrial segment will remain the largest end use industry due to increasing demand for optocouplers in smart grid, smart meter, power supply industries.

Optocouplers in the automotive segment will witness the highest growth during the forecast period due to the increasing usage of optocouplers in hybrid and electric vehicles.

Encapsulation Solutions For Optocouplers

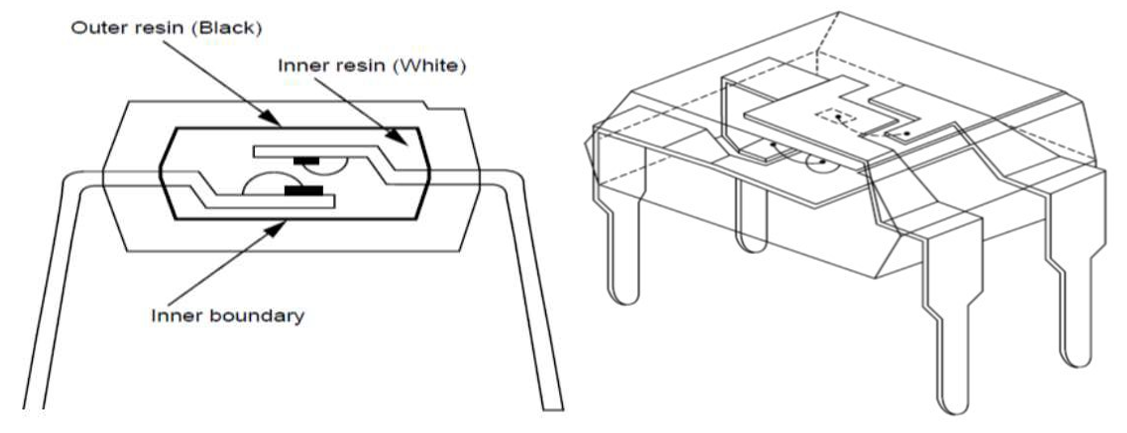

Typically, there are two types of packaging solutions for optocouplers using epoxy molding compound.

In this package, the inside white molding compound provides high light reflectance for planar structure and transmittance for single to pass through; the outer black epoxy molding compound largely improves the package reliability with moisture resistance and low thermal stress, compared with single mold design.

Key Material Considerations

Inner White

- Light transmittance >25%@1mm

- Dielectric voltage test (@6.3kV after 1hr@125°C PMC)

- Anti-blue decay < 20% @125°C, 1000hrs

- Bleed/Flash control, no wire sweep and voids

Outer Black

- MSL3 precondition tests (125°C/4hrs bake, 3 x IR reflow@260°C)

- Thermal cycling tests (-55~125°C, 300cycles)

- PCT (2atm/121°C/100%RH)

- Red ink penetration test (20mins immersion after PMC)

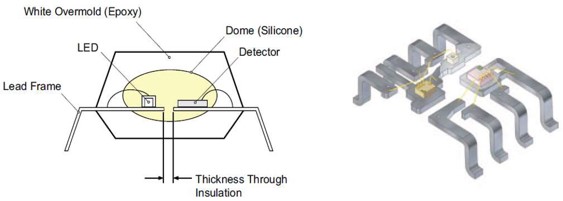

The white molding compound with TiO2 pigment added brings high reflectivity. It reflects the light signals from LED to the detector as much as possible. Since it also works as outside protection, it needs to ensure the reliability of the devices.

Key Material Considerations

- High light reflectance (>80%)

- High thermal and humidity resistance

- Anti-yellowing against heat and UV

- Good adhesion to silicone

- Good moldability, no flash/bleed, and wire sweep

- Pass required reliability tests after MSL preconditioning

Product Recommendations

White, highly reflective epoxy molding compounds, also abreviated as WMC, are epoxy molding compounds that are filled with a highly reflective filler that stays reflective even after exposure to heat and UV for long periods of time. We offer a range of highly reflective, white, non-yellowing epoxy mold compounds for led packages and lighting applications that require a high-performance non-yellowing compound with high brightness and reflectivity. After the plant closing of KYOCERA in Singapore, a lot of customers are seeking for substitutes of Kyocera KE-96/KE-95

We are happy to say that we have developed multiple alternatives of GT-W170 Series to Kyocera KE-96/KE-95 with high reflectivity and you can contact us to request samples.

PROPERTY | KE-96A | KE-96A5 | GT-W170-2 | GT-W170-15 | GT-W170-6 |

Epoxy Resin | OCN | OCN+Confidential | Multi-functional +BPA | OCN | Confidential |

Hardner | PN | Confidential | Anhydride | PN | Confidential |

Filler Content | 78% | 76% | 70~75% | 70~75% | 70~75% |

Filler Shape | Crush | Crush | Crush | Crush + Spherical | Crush |

Specific Gravity | 2.12 | 2.05 | 1.98 | 1.96 | 1.89 |

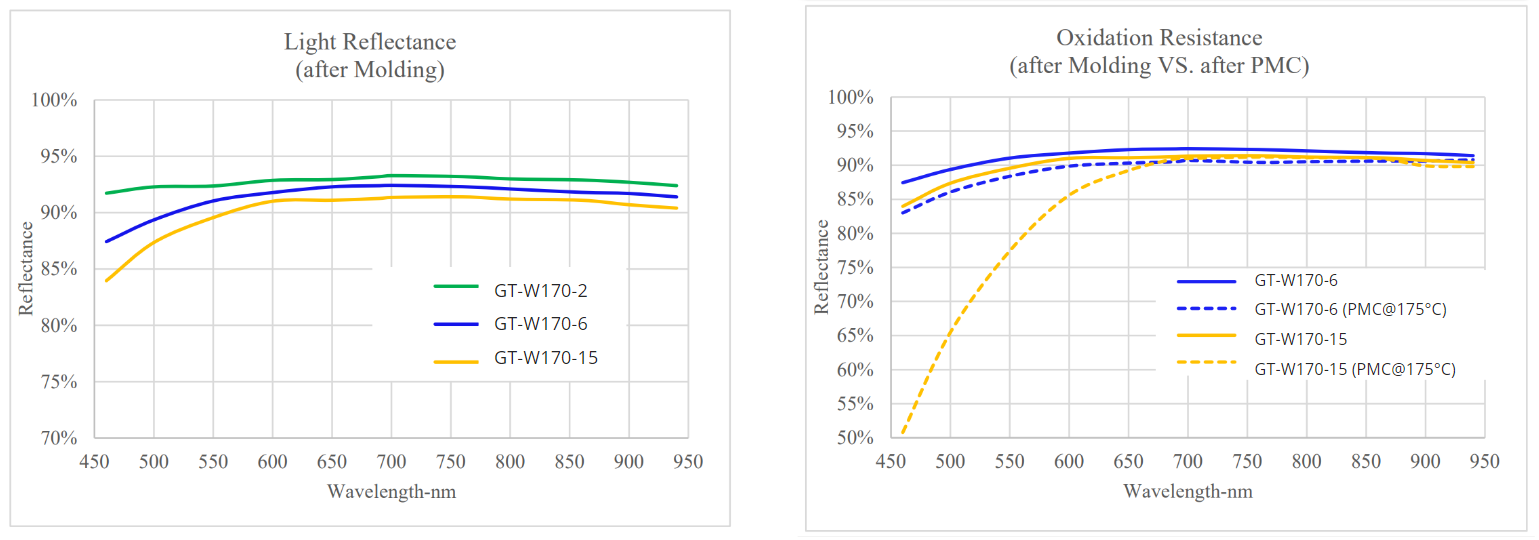

Light Reflectance 0.5mm @800nm | 87~89% | 75~79% | 93% | 91% | 91% |

Light Reflectance 0.5mm @940nm | 89% | 77% | 92% | 89% | 90% |

Reflectance & heat Resistance | ◼︎◼︎◼︎◼︎ | ◼︎◻︎◻︎◻︎ | ◼︎◼︎◼︎◻︎ | ||

Moisture Resistance | ◼︎◼︎◻︎◻︎ | ◼︎◼︎◼︎◻︎ | ◼︎◼︎◻︎◻︎ | ||

Molding Shrinkage & Stress | ◼︎◼︎◼︎◻︎ | ◼︎◼︎◻︎◻︎ | ◼︎◼︎◻︎◻︎ | ||

Moldability | ◼︎◼︎◼︎◻︎ | ◼︎◼︎◼︎◻ | ◼︎◼︎◻︎◻︎ | ||

Continuous Moldability | ◼︎◼︎◻︎◻︎ | ◼︎◼︎◼︎◻︎ | ◼︎◼︎◻︎◻︎ | ||

Key Advantage | High whiteness High reflectance Oxidation-resist | High MSL Good moldability | Balanced performance |

GT-W170 Reliability Test Results

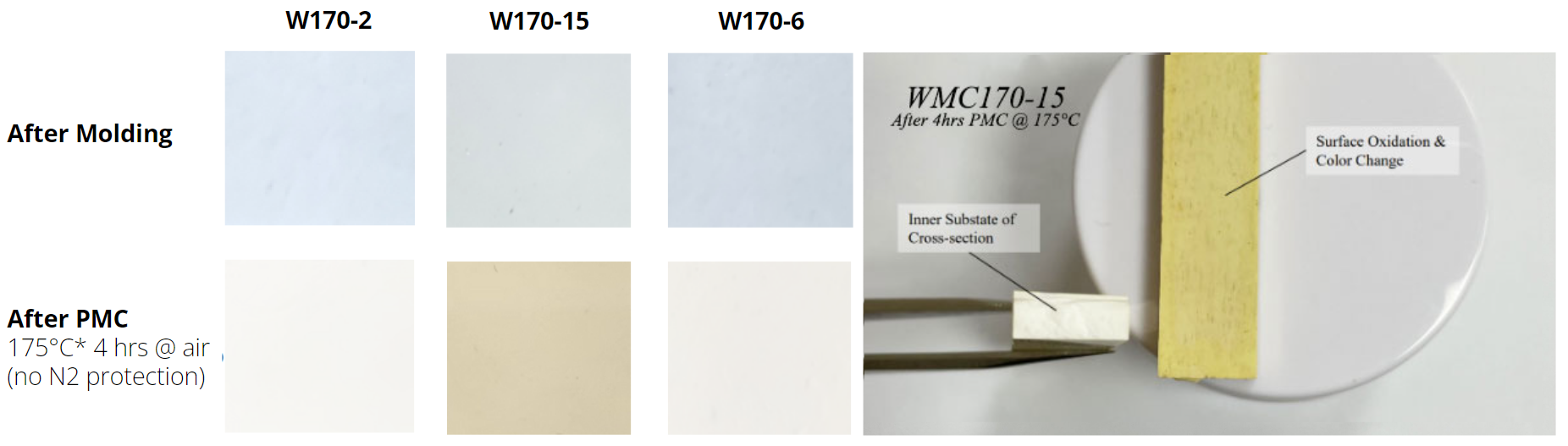

Anti-yellowing Capability: W170-2 > W170-6 > W170-15

Reflectance Decay By Yellowing:

- Wavelength > 700 nm: All the three samples show no obvious reflectance decrease by heat oxidation with PMC condition 175°C * 4 hrs

- Wavelength < 650 nm: WMC170-15 has shown reflectance value drop, which means yellowish color by heat oxidation

- WMC170-15: Only the surface contacting with air shows yellowish color, however, the inner material shows no color change.

- WMC170-2: No color change by heat oxidation

- WMC170-6: No color change by heat oxidation