Transistor Outline (TO)

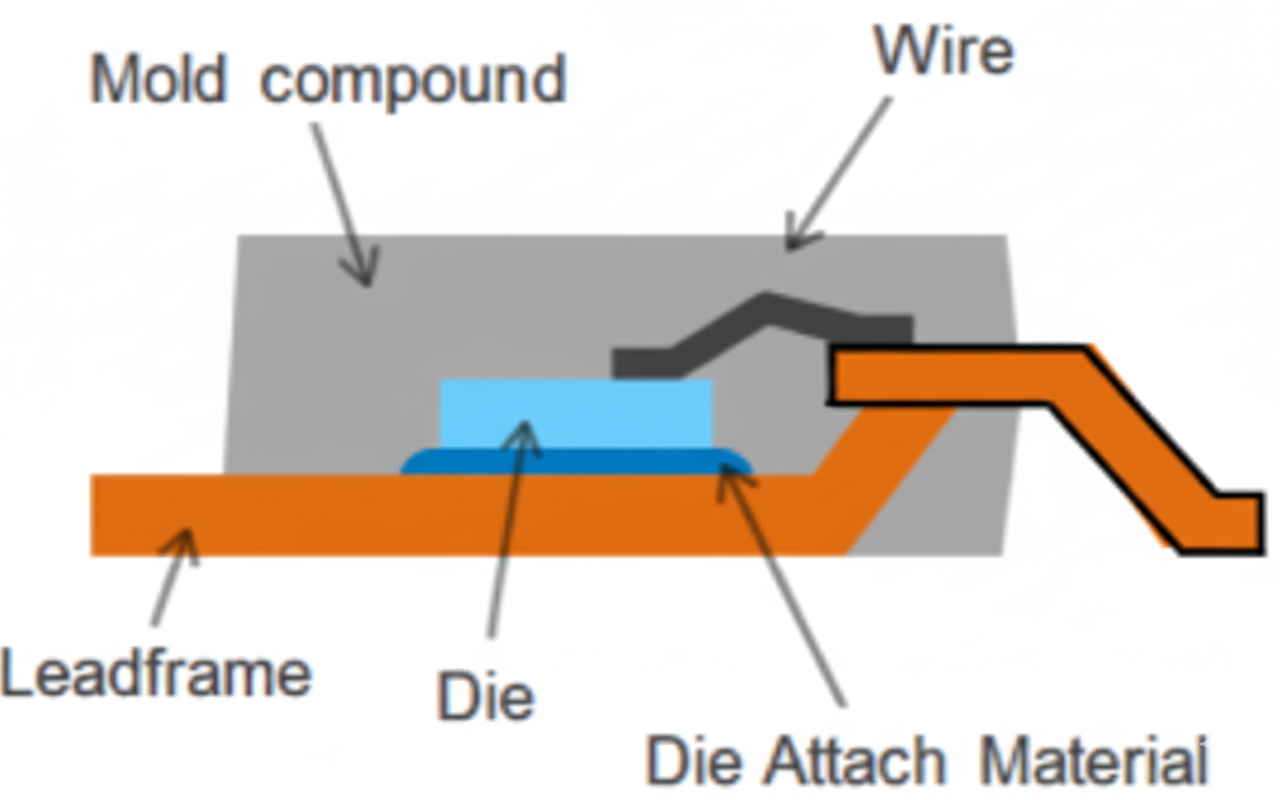

A common Bill Of Materials would include a Ni plated copper leadframe, Pb solder die attach, Al wire for the intereconnects and a molding compound to keep it all together.

Typical Applications The DPAK/D2PAK package is suitable for medium/high power applications designed for low on-resistance and high-speed switching MOSFETs, such as:

| Typical Reliability Test

|

Hysol GR600 Epoxy Mold Compound Chemistry

EMC Chemistry | GR600SL2 | GR600A | GR600 | |

Platform | TO252/251/263 | TO252/251/263 | TO252/251/263 | TO252/251/263 |

Resin Type | EOCN + LWA-3 | LWA-1 + LWA-2 | LWA-1 | MAR + Flexible |

Hardener Type | PN + LWA-1 | LWA-m | LWA-m | -- |

Filler Loading | 85±1% | 88±1% | 88±1% | 88±1% |

Filler Type | Spherical + Angular | Spherical | Spherical | - |

Catalyst | P/N | P/N | P/N | - |

MSL Performance | MSL3 (Cu/Ag plating) | MSL3 (Cu/Ag plating) | MSL1 (Cu/Ag plating) | MSL1 (Cu/Ag plating) |

Hysol GR600 Series Technical Specifications

Property / Product | Unit of Measure | GR600-SL2 | GR600-A | GR600 |

| |

UNCURED PROPERTIES |

| |||||

Hot Plate Gel time, @ 175°C | s | 25 | 41 | 28 | 38 |

|

Spiral Flow @ 175°C | in | 32 | 53 | 32 | 25 |

|

Flammability |

| 1/8’’ V-0 | 1/8’’ V-0 | 1/8’’ V-0 | 1/8’’ V-0 | UL94 V-0 |

Halogen-free (Green) | ✔ | ✔ | ✔ | ✔ | Green product | |

TYPICAL CURED PROPERTIES |

| |||||

Specific Gravity, g/cc | g/cc | 2.03 | 1.97 | 2.00 | 2.11 |

|

Glass Transition Temperature, TMA | °C | 153 | 113 | 122 | 124 |

|

Coefficient of Thermal Expansion (CTE) |

| 10 | 9.8 28 | 6.8 26 | 14 36 | Low CTE |

Viscosity, @175°C | Pa.s | TBD | 14 | 25 | 29 |

|

Flexural Strength, @25°C | MPa | 138 | 139 | 139 | 142 |

|

Flexural Modulus, @25°C | GPa | 19.1 | 19.8 | 17.6 | 19.8 | Low stress |

Storage Modulus (DMA), @25°C | Gpa | 26.1 | 24.7 | 27.0 | 25.8 |

|

Storage Modulus (DMA), @175°C | Mpa | 2798 | 736 | 1273 | 1312 |

|

Storage Modulus (DMA), @260°C | MPa | 923 | 599 | 897 | 863 |

|

Shore-D Hardness @ 90s, 175°C | - | 84 | 75 | 83 | 80 |

|

Moisture Absorption, 24hr PCT | % | 0.25 | 0.25 | 0.18 | 0.22 | Low water absorption |

TO-220 is a power package intended for power semiconductors and an example of a through-hole design rather than a surface-mount technology type of package. TO-220 packages can be mounted to a heat sink to dissipate several watts of waste heat.

TO-257 is a hermetically sealed metal package that is otherwise considered equivalent to TO-220.

Silicone Carbide TO Packages

TIMS are not the only product category that has to be "custom made" for power modules. High power requires not just dissipation but also thermally stable semiconductor materials that can withstand the rigourous thermal cycling requirements. These range from die attach, encapsulants and bonding wires to epoxy molding compounds.

Epoxy molding compounds such as the GR750 series and GR15F-MOD2C are made with power modules in mind. With exquisite thermal performance these compounds have a very high Glass transition temperature and easy pass HTRB tests while keeping high MSL levels. They are designed for high power devices with low moisture absorption requirements.

- Excellent Thermal Stability (Passes Thermal Cycling Test)

- High Tg as required

- Low weight loss by TGA test and low thermal expansion

- Excellent Electrical Stability (Passes HTRB Test)

- Low ion content and low ionic mobility at high power condition

- Stable ionic conductivity and permittivity at high temperature condition;

- Reliability for SiC MOSFETs Packages (Meets MSL Test Requirements)

- Low moisture absorption

- Low storage modulus

- Superior adhesion to lead frame

- Low Coefficient of Thermal Expansion (CTE)

- Environmentally Friendly

- Green material without Br/Sb comply with RoHS;

- Suitable for halogen-free devices defined by the Jedec JS709B;

Epoxy Molding Compounds for TO Through Hole Devices

| Package: TO92/TO126F | ||

| Non-Green | Green | Key feature |

| Hysol KL1000-3HL | Hysol KL-G200 | Superior moldability; Lower cost |

| Hysol MG20KF | Hysol GR260-SL | Good delam &electrical performance |

| Hysol KL1000-T | - | No void; Better operability; High Electrical |

| - | Hysol GR30HT | HTRB / TCT/Good Ni adhesion |

| Package: TO220/247/3P | ||

| Non-Green | Green | Key feature |

| Hysol KL1000-TH | - | High adhesion; High reliability |

Hysol KL1000-3HL | - | High adhesion; High reliability |

| Hysol MG20KF | Hysol GR260-SL(IMP3) | Lower cost; HAST 96h; HTRB 1000h; -TC500 |

| Hysol MG15F-35A Hysol MG15F-0140 | Hysol MG15F-MOD2C | Suit to high voltage application |

| - | Hysol GR300 | HTRB 1000h; Excellent delamination on Ni-plating devices |

| - | Hysol GR15F-A | Good moisture resistance,Excellent electrical performances, good adhesion to Cu/Ag/Ni., high thermal stability |

| - | Hysol GR30 | HTRB / TCT/Good Ni adhesion |

| - | Hysol GR30HT | Fast cure; Good Ni adhesion |

| - | Hysol GR400 | Better operability; High Electrical |

| - | Hysol GR750 | High Glass Transition Temperature, low moisture absorption, designed for high power SiC devices |

| - | Hysol GR750 X1/X2 | High Glass Transition Temperature, low moisture absorption, designed for high power SiC devices |

| - | Hysol GR700 C4/P2 | Low stress; Low moisture absorption; High reliability,designed for high power SiC devices |

| Package: TO 220F/3PF/126F | ||

| Non Green | Green | Key feature |

| Hysol KL5000HT | Hysol KL-G500HT | High thermal conductivity. (.2.0w/m.k, 0.3mm gap) |

| Hysol KL-G500HT-ST | Fast cure/High TC/Excelletn WS control on Cu wire/PCT / HTRB / TCT | |

| Hysol MG50HT | Hysol GR50HT | High thermal conductivity; Good electrical and delam performance (.2.0w/m.k, 0.3mm gap);HAST 96h; HTRB 1000h; TC1000c; Isolation test DC 4500V; Good workability |

| Hysol GR50HT-ST | PCT 168h; TC1000c; HTRB1000h; Auto mold with Ni-plating lead | |

Epoxy Molding Compounds for TO Surface Mount Devices

| Package: D2PAK (TO263) | |

| Product | Key Feature |

| Hysol KL-G680H | MSL1 for Ni-plating lead; HTRB1000h; TC500c |

| Hysol GR300 | HTRB 1000h; Excellent delamination on Ni-plating devices |

| Hysol GR600A | Ag/Cu plating lead & MSL3; Low moisture absorption; Excellent electrical performances |

| Hysol GR600-SL | Achieve JEDEC Level 3 on bare copper and nikel plated DPAK/D(2)PAK ; HTRB1000h; HAST96h |

| Hysol GR600 | Achieve JEDEC Level 1 on bare copper and nikel plated DPAK/D(2)PAK ; Excellent electrical performances |

| Hysol GR710 | Up to MSL3; Excellent electrical performances; HTRB1000h; |

| Hysol GR700 | MSL1, excellent electrical performances;designed for high power SiC devices |

| Hysol GR750 X2 | MSL1, excellent electrical performances;designed for high power SiC devices |

GR60HT | GR60PT | GR50HT | KL G500HT-ST | KL5000HT | GR760HT | GR770HT | ||

Application | Power module | TO(Fullpack) | Under development | |||||

Leadframe Type | Cu,Ni,Ag | Cu,Ag | Cu/Ag | Cu/Ag | Cu/Ag | Cu, Ag, Ni | Cu, Ag, Ni | |

Filler Type | / | Silica | Silica | Silica | Silica | Silica | Silica/Alumina | Alumina |

Filler shape | / | Angular | Angular | Angular | Angular | Angular | Angular/Spherical | Spherical |

Filler Cut size | μm | 150 | 150 | 150 | 175 | 150 | 150 | 75 |

Epoxy resin | / | EOCN+α1 | EOCN/α2 | EOCN+α1 | EOCN+α1 | EOCN+α1 | EOCN+α1 | EOCN+α1 |

Hardener | / | LWA | PN | PN | PN | PN | LWA | LWA |

Flammability @ 1/8" | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | |

Spiral Flow @175°C | cm | 58 | 89 | 46 | 41 | 51 | 51 | 64 |

Gel time(s) @175°C | S | 35 | 34 | 30 | 23 | 20 | 40 | 30 |

Hot Hardness @175°C90S | / | 80 | 80 | 73 | 80 | 84 | 80 | 74 |

CTE1 | *E-5/℃ | 19 | 20 | 20 | 20 | 21 | 18 | 11 |

CTE2 | *E-5/℃ | 44 | 60 | 62 | 66 | 61 | 44 | 27 |

Tg | ℃ | 119 | 165 | 170 | 155 | 175 | 133 | 111 |

Flexural strength | N/mm2 | 137 | 120 | 118 | 139 | 115 | 119 | 126 |

Flexural modulus | N/mm2 | 19625 | 18000 | 15125 | 14475 | 13330 | 18847 | 23532 |

Water absorption ( Boiling, 24hrs) | % | 0.2 | 0.3 | 0.36 | 0.37 | 0.29 | 0.2 | 0.16 |

Thermal Conductivity | W/mK | 2.2 | 1.8 | 2.0 | 1.8 | 1.9 | 3.0 | 4.8 |