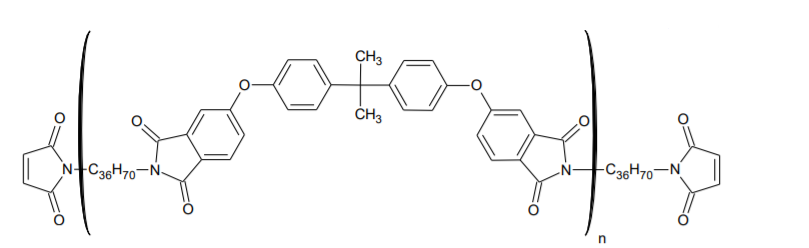

BMI-1700 Amorphous, Low Molecular Weight Bismaleimide Oligomer

- Soluble in many reactive diluents

- High adhesion to various substrates

- Superior thermal stability

Product Description

BMI-1700 is an amorphous, low molecular weight bismaleimide oligomer that exhibits good adhesion to a variety of substrates. It can be homo-cured via UV or free radical initiators to form tough, hydrophobic, cross-linked polyimides. The material has excellent low pH hydrolytic resistance and thermal stability. The amorphous nature of this imide-extended BMI allows it to form room-temperature-stable solutions in a variety of free radical reactive diluents. It is soluble in most aromatic and aliphatic solvents such as toluene, xylene, NMP, etc.

BMI-1700 is recommended for use as an additive or base resin in adhesives that are designed for high temperature resistance. It has excellent adhesion to a variety of substrates. When used as a base resin, it can produce films that are tough, flexible and demonstrate good peel strength.

Technical Specifications

| General Properties | |

| Appearance Appearance Appearance at room temperature. | Amber, high viscosity liquid |

| Functionality | 2 |

| Molecular weight | 1715 g/mol |

| Thermal Properties | |

| Decomposition Temperature | >400 °C |

| Operating Temperature | 180 °C |

| Weight Loss @ 300°C | 1.5 % |

| Other Properties | |

| Storage Temperature | Room temperature °C |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 37500 mPa.s |

Additional Information

How does BMI 1700 adheres to various substrates?

An evaluation of adhesion was performed using BMI-1700 (part number R1191) and various quantities of epoxy

- Aluminum studs cured onto various substrates, cured for 1 hour at 175ºC

- >230 indicates machine maximum reached, no breakage

Average Adhesion Values – R1191/ Epoxy Mixtures (Pounds Force) | |||||

Substrate | Control R1191 2% DCP | Control R1191 4% 1-B2MZ

| Mixture A R1191 + 15% Epoxy 4% 1-B2MZ | Mixture B R1191 + 25% Epoxy 4% 1-B2MZ | Mixture C R1191+ 35% Epoxy 4% 1-B2MZ |

Ceramic | 109 | 67 | >230 | >230 | 211 |

Stainless Steel | 152 | 75 | >230 | >230 | >230 |

Aluminum | 149 | 56 | >230 | 215 | 207 |

Copper | 81 | 41 | 135 | 108 | 105 |

TDS states that BMI 1700 has the same Molecular weight with BMI 1400 but their Viscosity is different. Is this correct?

Good question. The TDS documents are a little (a lot?) misleading. The molecular weight (MW) referenced on the TDSs is for the idealized structure where n (the number of repeating units) =1. Since BMI-1400 and BMI-1700 are siblings - made from the same raw materials and using the same process - they share the same basic molecular structure as shown on the top of each TDS.

In actuality, BMI-1400 and BMI-1700 are oligomers which means they are made up a number of different MW species (e.g. n = 1 to 10). We change the ratio of starting materials in order to grow the backbone larger in the BMI-1700 (higher "n" value) and smaller in the BMI-1400 (lower "n" value) which corresponds to higher average MW and lower average MW respectively. The average MW directly influences the viscosity so that is why there are differences in viscosity between the two products.

BMI 1400 GPC Chromatograph

This MW difference can be seen in the Gel Permeation Chomatography traces for the two products:

- The traces show the products separated into groups (peaks) by MW with the highest values on the left and the lowest values on the right.

- The large peak around 24.8 minutes is the BMI-689 component which keeps these products liquid.

- The next peak to the left (~22.2 minute retention time) is the n=1 or idealized structure component.

- Moving to the left you can see that BMI-1700 has a higher number of peaks and a larger area under the curve indicative of a larger percentage of the product is of a higher MW when compared to the BMI-1400.

BMI 1700 GPC Chromatograph

When we actually measure the MW of the two products we do see a difference: the weight average molecular weight (Mw) is 5,000 - 7,000 Daltons for the BMI-1700 and less than 4,000 Daltons for the BMI-1400 which ties to the viscosity differences.