BMI-3000 Gel Bismaleimide (Imide Extended)

- Superior thermal stabilty

- Hydrophobic

- Toughener

Product Description

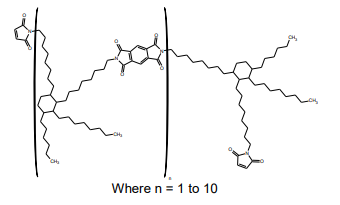

BMI-3000 GEL is a bismaleimide oligomer that exhibits excellent flexibility and, on cure, forms very tough, hydrophobic polyimides. The material has excellent hydrolytic stability and thermal stability. As an additive it can improve rheological properties by increasing the thixotropic properties of a liquid monomer composition. This feature in turn can help to reduce resin bleed out on a variety of surfaces. It is soluble in most aromatic and aliphatic solvents such as toluene, nmp, etc. BMI-3000 GEL is compatible with and can be incorporated directly into many resin systems for enhanced performance.

Technical Specifications

| General Properties | |||||

| Appearance Appearance Appearance at room temperature. | Red-amber gel | ||||

| Functionality | 2 | ||||

| Molecular weight | 3000 g/mol | ||||

| Thermal Properties | |||||

| Decomposition Temperature | >400 °C | ||||

| |||||

| Other Properties | |||||

| Storage Temperature | Room temperature °C | ||||

Additional Information

Frequently Asked Questions about High Glass Transition Temperature Epoxy Molding Compounds

What is the difference between the Gel and Powder versions of BMI-3000?

Not a whole lot in terms of final product performance. The basic product and properties are the same, and both have the same molecular weight (3,000 daltons). The difference is in the processing. Both of them have a similar reaction process, but at the end, the handling (including the solvent removal) is different, resulting in a different physical form (Gel vs. Powder). Gel is easier to handle, but the Powder is easier to mix into the formulations.

Which product is less expensive the BMI-3000 Gel or the BMI-3000 CG Powder?

Although the reaction cost is the same and the BOM cost is similar, the Gel will ultimately be less expensive to buy in higher quantities. This is because of the handling of material after the reaction is complete. Though the "Commercial Grade" CG Powder is less expensive to produce, the handling afterward makes it a more expensive end product.

What is considered "high volume" production?

Many of the current products are made in 40-gallon reactors and we have the capability to run up to 200-gallon reactors which will yield around 100kg. We do have the capability to increase these batch sizes if needed to meet higher production batches and can be turned on on an "as-needed" basis.

Is the low-volume material produced the same as the high volume material?

Yes. We have many, many years of experience in scaling up formulated liquids. Although the production equipment gets bigger, the process is the same and scalable.