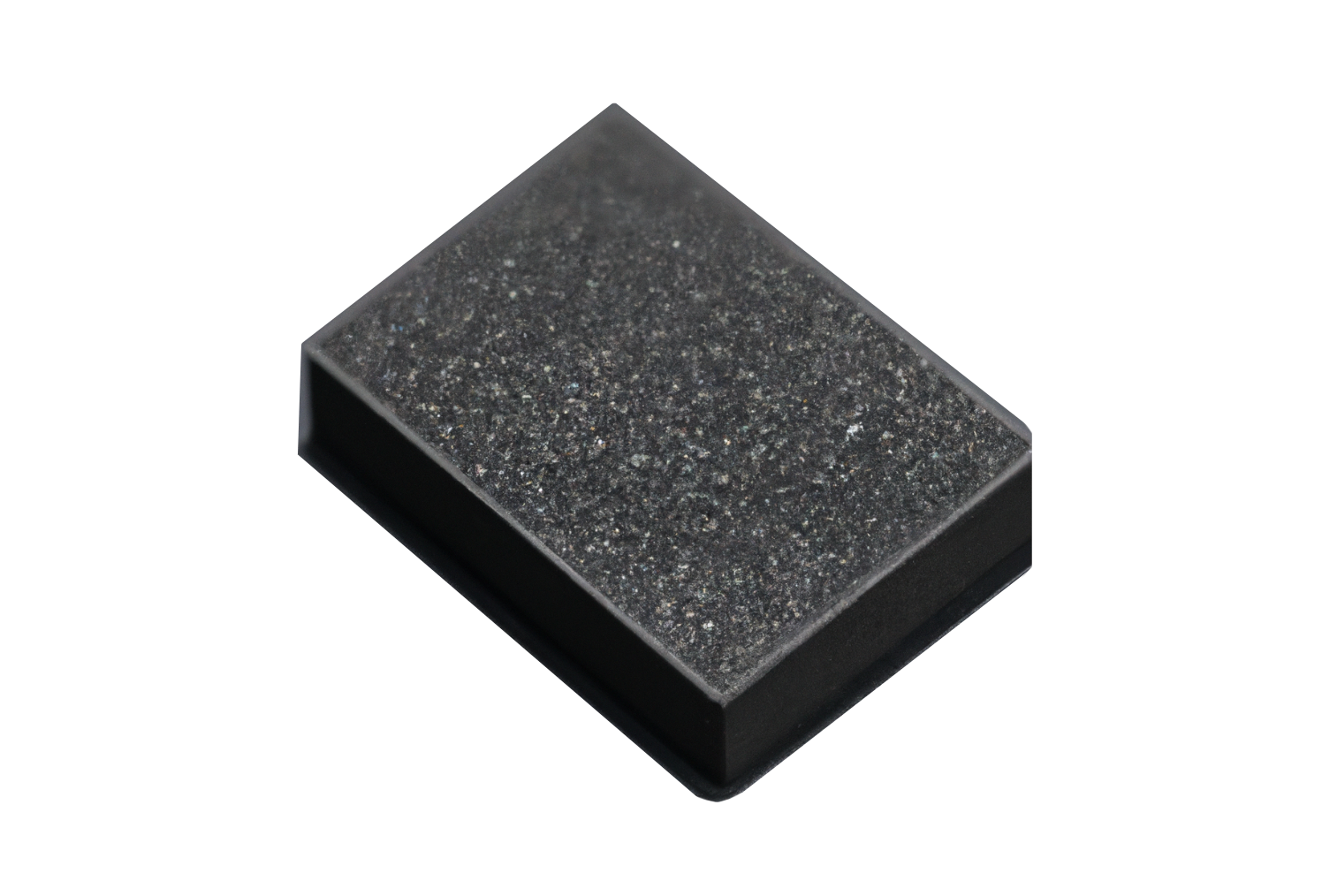

COOLINQ SG-90 | Graphite Heat Spreader

- 90um Graphite

- Light weight and flexible

- Excellent thermal conductivity

Product Description

COOLINQ SG-90, the ideal solution for achieving exceptional thermal management across various industries, ranging from consumer electronics to aerospace and beyond. This innovative graphite sheet is engineered to efficiently distribute and dissipate heat, ensuring consistent peak performance of electronic components, even under the most demanding conditions.

COOLINQ SG-90 boasts a slightly thicker profile, measuring at 0.090mm, offering enhanced properties. Despite the increase in thickness, it maintains its lightweight and flexible nature, allowing seamless integration into electronic devices without introducing unnecessary bulk. Its adaptability extends beyond consumer electronics, making it the preferred choice for applications in the automotive, aerospace, and industrial sectors.

One of the standout features of COOLINQ SG-90 is its exceptional durability, now with enhanced thermal conductivity. Engineered to withstand wear and tear, it provides long-lasting thermal management solutions for your applications. Furthermore, its ease of integration remains a key advantage. Unlike rigid metal heat spreaders, COOLINQ SG-90 can be readily cut, shaped, or layered to precisely fit your unique application, making it a versatile addition to your thermal management toolkit.

Key Applications:

- Consumer Electronics: COOLINQ SG-90 elevates the thermal performance of everyday gadgets, ensuring optimal operation, even under challenging conditions.

- Automotive: Enhance the efficiency and reliability of automotive electronics, maintaining their performance across diverse operating conditions with improved thermal conductivity.

- Aerospace: In critical aerospace applications, COOLINQ SG-90 stabilizes electronic systems and extends their operational lifespan while providing enhanced thermal conductivity.

- Industrial Equipment: Improve the performance and longevity of industrial electronics and machinery with COOLINQ SG-90's superior thermal conductivity.

COOLINQ SG-90 brings advanced thermal management to the next level with its increased thickness, catering to applications that demand higher thermal conductivity.

Technical Specifications

| General Properties | |

| Density (g) | 1.5 g/cm3 |

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 900 μm |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 450 W/m.K |

Additional Information

Frequently asked Questions

How are Graphite sheets made?

COOLINQ SG90 Graphite Sheets are manufactured using advanced processes that ensure consistency and precision. Our proprietary manufacturing techniques result in sheets with uniform thickness, exceptional thermal conductivity, and minimal defects. This level of quality control ensures that every sheet you receive meets the highest industry standards.

Are graphite sheets better than metal spreaders?

COOLINQ SG90 Graphite Sheets have a clear advantage over traditional heat-spreading technologies, particularly those of the same thickness. Conventional materials like metal heat spreaders are heavier and less flexible, limiting their applicability in compact and lightweight electronic devices. In contrast, COOLINQ SG90's thin profile at just 0.090mm offers an unprecedented combination of heat spreading efficiency and flexibility. It is remarkably lightweight and can be effortlessly integrated into even the most space-constrained electronics.

What is the Thermal Conductivity of Graphite sheets?

What sets COOLINQ SG90 apart is its remarkable thermal conductivity, which surpasses that of many other materials at the same thickness. Thanks to its highly oriented pyrolytic graphite (HOPG) composition, it excels at rapidly conducting heat in both the X-Y (400-450 W/mK) and Z (10-20W/mK) directions. This makes it an ideal choice for scenarios where efficient heat dissipation is paramount.

Handling and Storage

Handling: To prevent contact with graphite powder, it is advisable to wear gloves and a smock during handling.

Storage: Store the product away from potential ignition sources and oxidizing materials. Ensure it is kept in a cool, dry place, sealed tightly within a container.

Operator Protection

Adequate ventilation is recommended during operation.

While no specific skin protection is necessary, it is advisable to use eye protection when working with the product.

Due to its high thermal conductivity, avoid direct contact with the product when the operating temperature exceeds 60°C or falls below freezing.

Safety Precautions

Strictly adhere to the specified working temperature range of -50 to 250°C.

Avoid using the product with acidic substances.

Prevent any rough handling, rubbing, or collision with sharp objects.

When cutting the product, use a knife rather than tearing it by hand.