Flip Chip

Flip chip assemblies are much smaller than traditional carrier-based systems. The chip sits directly on the circuit board, and is much smaller than the carrier both in area and height. Having short wires or solder balls greatly reduces inductance, a property that allows higher-speed signals and better heat conductivity.

On the flipside (heh) flip chips are not suitable for easy replacement, or manual installation. They also require very flat mounting surfaces, which is not always easy to arrange, and they are sometimes difficult to maintain as the boards heat and cool. Also, the short connections are very stiff, so the thermal expansion of the chip must be matched to the supporting board or the connections can crack.

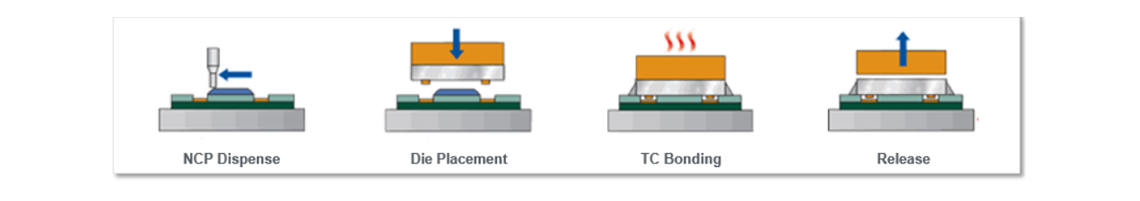

Thermal compression bonding applications require specific products that can protect the joints, aid the adhesion but also not short circuit the pillars. For example, ACP 3122 is an anisotropic adhesive designed for high throughput thermal compression bonding applications. It is a snap curable epoxy that conducts only in the Z axis.

Additionally, LOCTITE® ECCOBOND NCP 5209 is a non-conductive paste (NCP) underfill designed to facilitate next-generation fine-pitch copper pillar and copper OSP flip-chip devices.

Recommended products for Smartcard flip chip applications:

| Product | Tg | CTEa1 | Viscosity | Applications | Type |

| ACP3122 | 100 | - | 22,000 | Thermal compression/Multi | Anisotropic Conductive paste |

| NCP5209 | 145 | 28 | 12,500 | Thermal compression | #1 Non conductive paste Underfill |

| FP4531 | 161 | 28 | 10,000 | Snap cure. Flex applications | Capillary Underfill |