Wire Bonded

Wirebonded smart card modules are typically going through the following process:

- Dispense die attach

- Place die on the substrate and Heat Cure

- Wire bonding

- Apply encapsulant and Cure (Heat or UV)

- Dimension and position of Encapsulation

The dispensing volume needs to be fast and constant (10-15k UPH) and ensure that they minimize the wear out and maintain a long life time of the dispense head.

Encapsulation

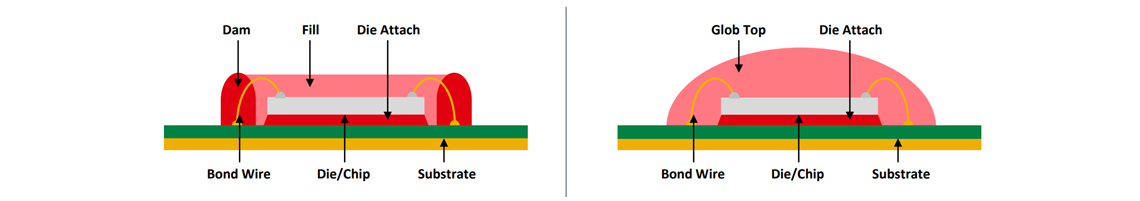

Dam and Fill is a method that uses a highly thixotropic and accurate dam around the die and then floods it with the fill. This method enables tighthly controlled height, dispensing and board design. It is the ideal solution for larger dies, such as sim cards, and mainly for dies up to 10x10mm. It is typically square to evenly distribute the stress, post cure.

Glob top is a more simplistic and less controlled dispensing method that is used for smaller dies. It is easier to flow uncontrollably around the chip and the end result is usually thicker since we need a bigger "blob" in the middle to cover everything around it. It is the industry standard since it is generally faster and requires fewer processing steps.

There are Heat and UV cure options for both methods.

Products recommended for Smartcard Encapsulation:

| Dam | Fill | Glob Top | |||

| UV Cure | Heat Cure | UV Cure | Heat Cure | UV Cure | Heat Cure |

| - | FP4451 | UV8800M-X | FP4450HF | UV8800M-X | EO1016 |

| FP4451TD | EO7021 | ||||

Die attach for Smartcard IC

| 2030SC | 2030SCR | 8384 | ACP3122 | 2033SC | 2035SC | 2035SCR | ABP2501 | 8387BM | EO7029 | ATB110U | NCP5209 | |

| Conductivity | Conductive | Non Conductive | ||||||||||

| Chemistry | Hybrid | Hybrid | Epoxy | Epoxy | Hybrid | Hybrid | Hybrid | Hybrid | Epoxy | Epoxy | Epoxy | Hybrid |

| Type | Paste | Paste | Paste | Paste | Paste | Paste | Paste | Paste | Paste | Paste | Film | Paste |

| Cure | 90s @110°C | 120s @120°C | 180s @130°C | 5s @150°C (TC) | 90s @110°C | 90s @110°C | 120s @120°C | 90s @110°C | 60min @100°C | 5min @150°C | 30min @120°C | 2-4s @250°C (TC) |

| Modulus@RT | 3300 | 1500 | 4800 | 2400 | 2100 | 2500 | 1500 | 1430 | 1900 | NA | 875 | 7300 |

| Modulus@150°C | 350 | 240 | 190 | 200 | 30 | 70 | 80 | 80 | 120 | NA | 3 | NA |