LINQCELL GDL2000 | 2.0mm Carbon Plate

- 2.0mm - 2000um - 78.7mil

- Ideal for electrolyzers

- Graphitized Carbon Plate

Product Description

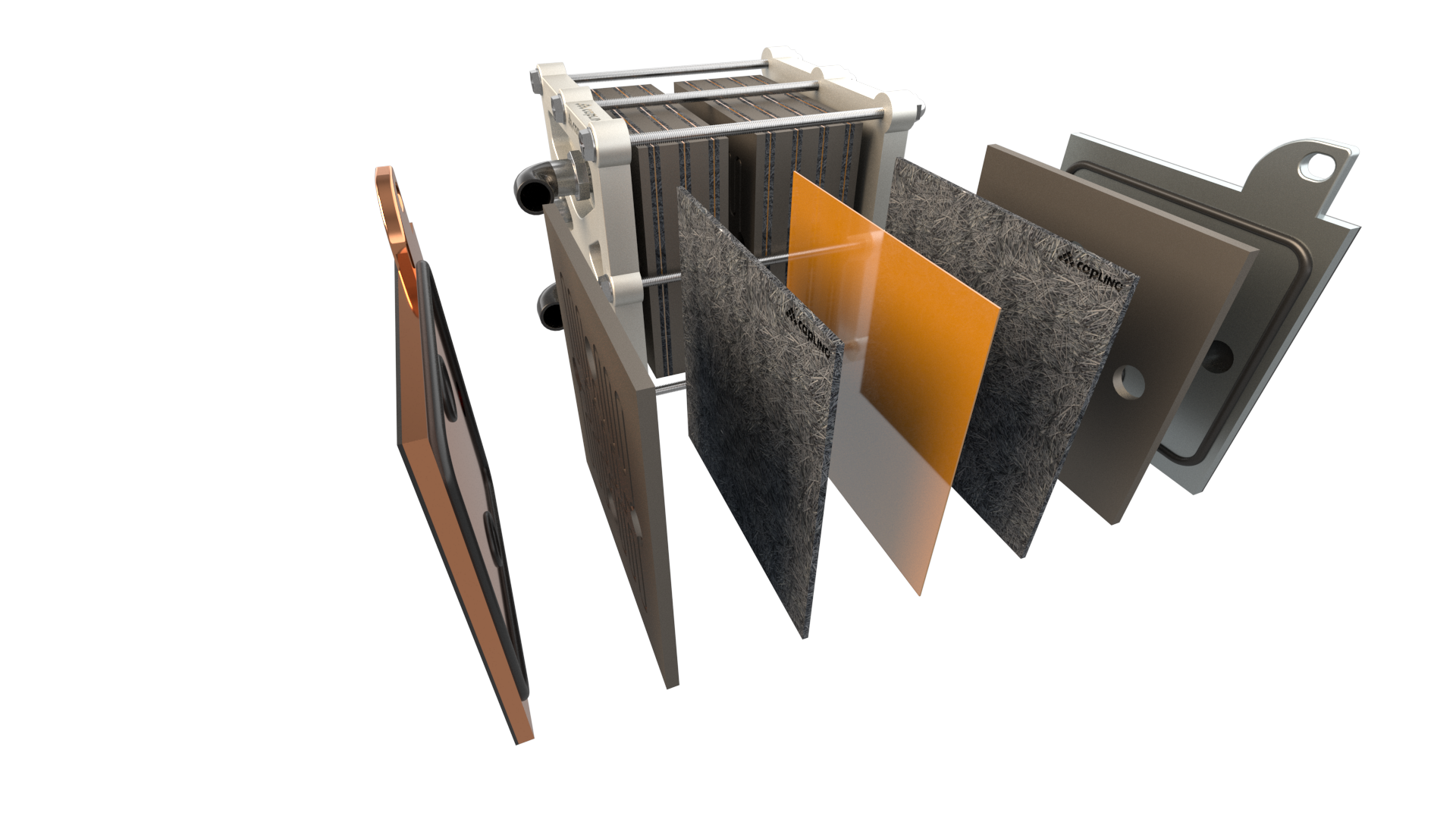

LINQCELL GDL2000 is a high-performance graphitized carbon plate that can be used as a gas diffusion layer in fuel cells or porous transport layer in water electrolyzers. Its nominal thickness at 50 kPa is 2.00 (±0.1) mm.

LINQCELL GDL2000 offers low through-plane electrical resistivity and voltage loss, which are crucial for excellent electrical performance during fuel cell or water electrolysis operations. Its low compressibility ensures that it maintains its porous structure, enabling optimal material transport for chemical reactions even under compression.

This product can be graphitized at 1600°C and 2000°C. Higher graphitization results in better electrical performance and a more compressible material while significantly increasing the material cost. It is mainly recommended when resistivity is of the utmost importance. You can check our blog to find out how graphitization affects the structure and properties of carbon papers

Key Features:

- Excellent through plane resistance (10.7 mΩcm2 @ 2000°C)

- High compressibility (1.94% @ 1600°C and 3.4% @2000°C)

- Very low impurities

- Cheaper and more cost efficient than sintered titanium

Its high compressibility and porosity make it an excellent choice for optimal reactant transport to the catalyst layer, ensuring the best possible performance in various fuel cell applications. Its low electrical resistance, high thermal conductivity, and durability also make it ideal for use as a Porous Transport Layer (PTL) in PEM electrolyzers, PEMFCs, and PAFCs.

Highly Recommended for:

This highly graphitized carbon paper excels in meeting the stringent requirements of fuel cells and water electrolyzers, supporting catalysts and functional layers, facilitating gas and liquid transport, and conducting heat and electricity effectively.

Technical Specifications

| General Properties | |

| Basis Weight Basis Weight Basis weight refers to the weight measured in pounds off 500 sheets of paper in that paper’s basic sheet size. | 1302 g/m2 |

| Density (g) | 0.65 g/cm3 |

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 2.0 μm |

| Electrical Properties | |

| TP Resistance TP Resistance Opposition to the flow of electric current. | 10.7 mΩcm2 |

| Through Plane Resistivity Through Plane Resistivity Resistance of the amount of current through a material | 51.7 mΩcm |

| Voltage loss | 29.8 mV |

Additional Information

LINQCELL GDL2000 Properties

| Property | Graphitized at 1600°C | Graphitized at 2000°C | Unit | Test Method |

| Thickness @ 50 kPa | 2.06 | 2.06 | mm | ASTM D645 |

| Thickness @ 2 MPa | 2.02 | 1.99 | mm | ASTM D645 |

| Compressibility @ 100 kPa | 1.94 | 3.40 | % | - |

| Nominal Basis weight | 1282 | 1302 | g/m2 | ASTM D646 |

| Through plane Resistance | 13.39 | 10.7 | mΩcm2 | ASTM C611-98 |

| Through plane ResistivIty | 65.75 | 51.7 | mΩcm2 | ASTM C611-98 |

| Voltage Loss | 31.9 | 29.8 | mV | - |

Chemical Composition

| Test Items | MDL [ppm] | GDL2000 |

| Iron | 10 | 67.3 |

| Copper | 10 | n.d |

| Chromium | 10 | n.d |

| Zinc | 10 | n.d. |

| Calcium | 10 | 345 |

| Aluminum | 10 | 54.7 |

| Sodium | 10 | 86 |

| Magnesium | 10 | 44.5 |

| Potassium | 10 | 142 |

| Lead | 10 | n.d |

| Nickel | 10 | n.d |

| Manganese | 10 | n.d |

- MDL = Method Detection Limit

- n.d = Not detected

- Test method: With reference to USEPA 3050b: 1996, analysis was performed by ICP-OES

Storage and Handling

Shelf life is more than 2 years if stored in a dry and cool, well ventilated place at room temperature.

Do not leave exposed to moisture and sunlight for long periods of time.

Do not throw the plate or put heavy pressure on it and the box to avoid breakage.

Do not apply uneven pressure on the sheet.