HW-HSPS | Heat Spreader - Progressive Stamping

- Nickel plated / Au Spot

- Small and medium form factors

- Simplified parts - Lower volumes

Product Description

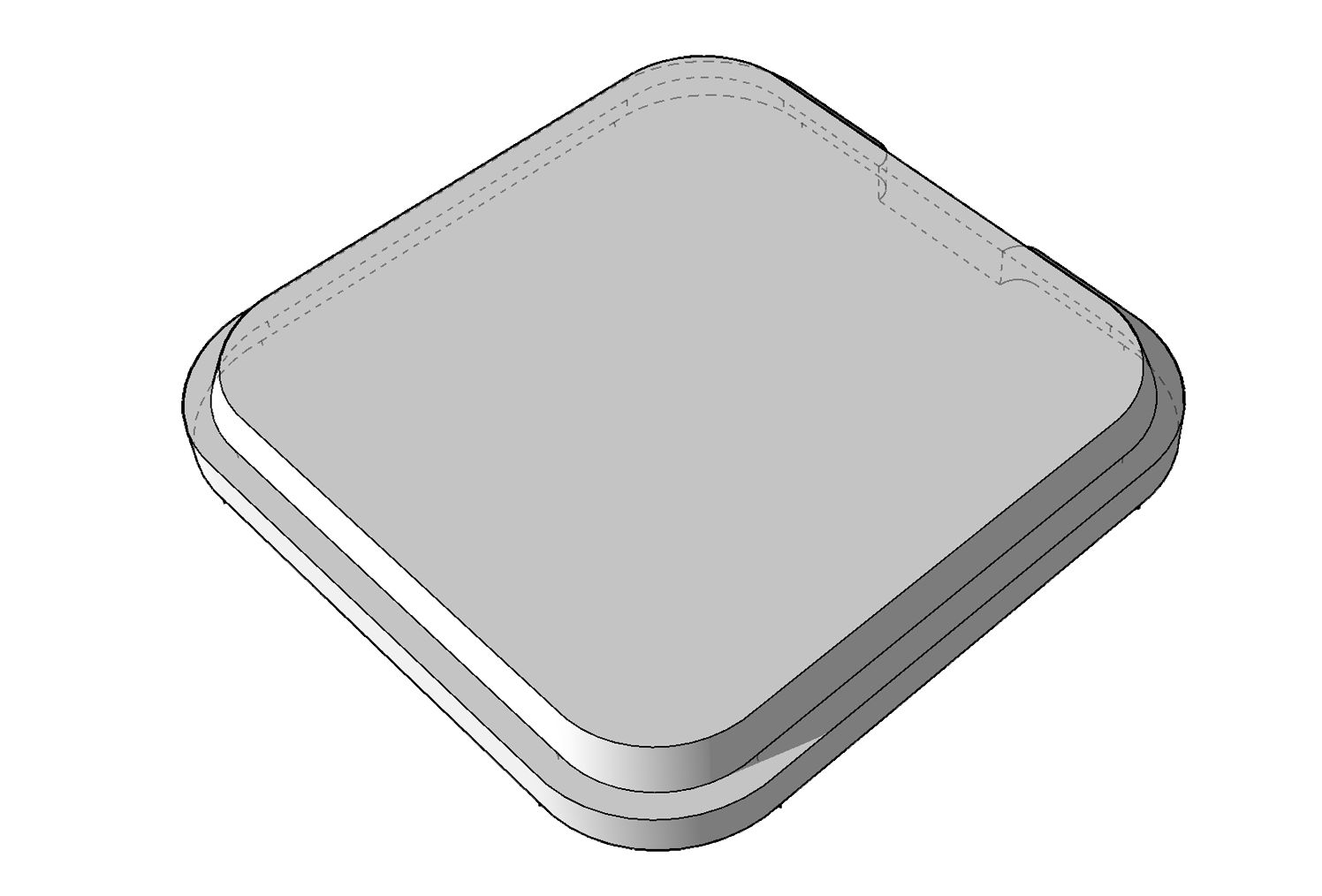

Honeywell HW-HSPS heat spreaders are used to dissipate heat from the chip. Heat spreaders can be produced in two different ways, by progressive stamping, and by transfer die stamping. Progressive stamped lids (heat spreaders) can be produced in Small Form Factor (SFF) & Medium Form Factor (MFF) parts. The maximum size of lids made with progressive stamping is 46.5 x 50mm. Heat spreaders are always plated with Nickel (Ni) (semi-bright / dull) and can also be plated with Gold (Au) with selective spot plating, in order to comply with the 24K / Mil spec.

Honeywell HW-HSPS heat spreaders are made with Progressive stamping process and enable simple part designs and low-volume, semi-batch processes. They are ideal for simple designs that won't require mass-scale, complex production. If you require high volumes then it probably makes more sense to invest in transfer die, where the upfront costs will be higher, but mass-scale production is expected to be cheaper, in the long run.

Technical Specifications

Additional Information

Progressive stamping - Heat spreader manufacturing process

The manufacturing of progressive stamping contains six steps that can be seen in the image below.

Production capability of progressive stamped heat spreaders

| Capability / Tolerances | HW-HSPS |

| Max size (mm) | 46.5 X 50 |

| OD & ID (mm) | ±0.05 |

| Radii (mm) | >0.30 |

| Seal band with (mm) | ±0.050 |

| Thickness (mm) | 0.5 - 3.5 |

| Topside & Cavity flatness by part area (40mm2) in (mm) | 0.04 |

| Topside & Cavity flatness by part area (50mm2) in (mm) | 0.07 |

| Flange Width (mm) | ±0.10 |

| Cavity Depth (mm) | ±0.05 |

| Surface Profile (mm) | ±0.003 |