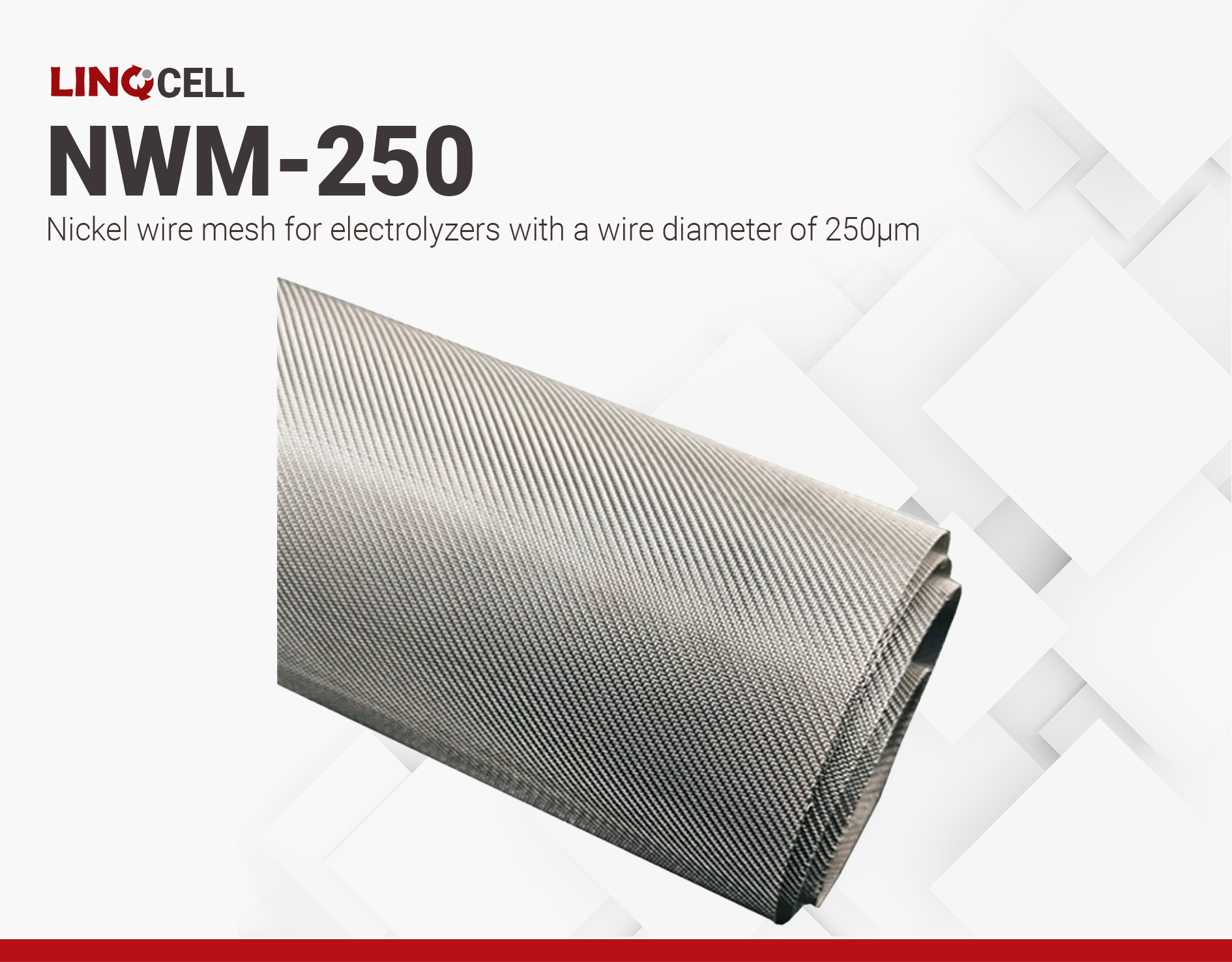

LINQCELL NWM 250 | 0.25mm Nickel Wire Mesh

- 0.25 mm wire diameter

- Excellent chemical stability and anti-corrosion resistance

- High electrical conductivity

Product Description

LINQCELL NWM250 is a finely woven wire mesh made from high-purity nickel alloy, with a wire diameter of 0.25 mm and a nickel content of at least 99.9%. Its mesh size and uniformity complies with GB/T 17492. This mesh offers excellent electrical conductivity, chemical stability, corrosion resistance, and mechanical durability. Its versatile properties make NWM250 suitable for different electrochemical devices, including water electrolyzers, fuel cells, and batteries, such as nickel–metal hydride (NiMH) and nickel–cadmium (NiCd) batteries.

Key Features:

- High corrosion resistance

- Very low impurities

- Cheaper and more cost efficient than sintered titanium

In water electrolyzers and fuel cells, LINQCELL NWM250 can be used both as a gas diffusion layer, facilitating mass and electron transfer within the device, and gas diffusion electrode when catalyst layers are directly applied to it. Its suitability for alkaline systems has established it as a standard electrode material in alkaline water electrolyzers.

Highly Recommended for:

- Porous transport layer for water electrolyzers

- Fuel cell gas diffusion layer

- Electrodes for alkaline water electrolyzers

LINQCELL NWM250 comes in different mesh counts (30, 40, 46, and 60, allowing precise tuning of diffusivity to meet various device design requirements. It is also available in two Ni grades: N4 (Ni201), and N6 (Ni200).

Technical Specifications

| Mechanical Properties | |||||

| Elongation Elongation Elongation is the process of lengthening something. It is a percentage that measures the initial, unstressed, length compared to the length of the material right before it breaks. It is commonly referred to as Ultimate Elongation or Tensile Elongation at break. | 27–28 % | ||||

| |||||

Additional Information

Alkaline Electrolyzer (1 Nm3/h) Test Data

Test Conditions

- Electrode: Φ200 mm, 46 mesh (0.25 mm wire diameter) Raney Nickel

- 24 units of electrolytic chambers

- Applied current and voltage: 4700 mA/cm2 and 1.95 V

- Temperature: 70 °C

Test Result

- Power Consumption: 4.58 kWh/Nm3

Chemical Composition

| Element | Expected Concentration, Ni200 [wt%] | Measured Concentration [wt%] |

| Nickel | >99 | 99.36 |

| Iron | <0.4 | 0.21 |

| Silicon | <0.35 | 0.15 |

| Copper | <0.25 | 0.12 |

| Sulfur | <0.01 | 0.001 |

| Manganese | <0.35 | 0.16 |

Mechanical Properties

| Property | Value | Unit |

| Elongation at Break | 27–28 | % |

| Tensile Strength | 418 | MPa |