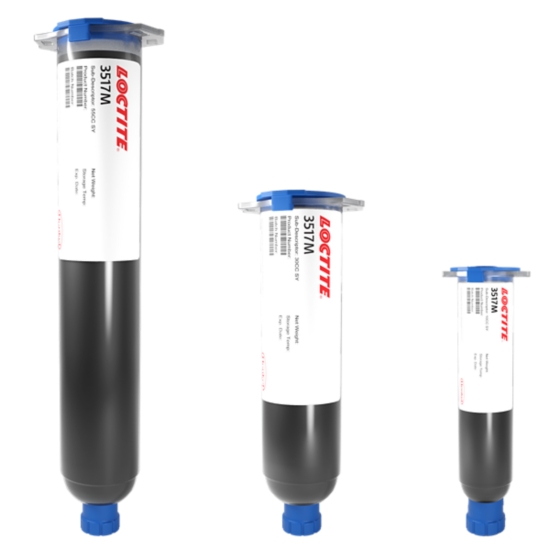

LOCTITE 3517M

Harmonization Code : 3907.30.00.90 | Polyacetals, other polyethers and epoxide resins, in primary forms; polycarbonates, alkyd resins, polyallyl esters and other polyesters, in primary forms : Epoxide resins : Other

Main features

- Reworkable

- No filler

- Low halogen content

Product Description

LOCTITE 3517M underfill is a heat curable epoxy, designed for use as a solder joint protection against mechanical stress in hand held electronic device applications.

LOCTITE 3517M underfill is typically used for CSP (Chip Scale package), Flip chip BGA and Ball grid Array package applications.

LOCTITE 3517M underfill contains no filler and is therefore suitable to be used in very low spaces. It contains hardener particle with an average size of 6µm and a maximum particle size around 30µm.

Cure Schedule

- 5 minutes @ 120°C or

- 10 minutes @ 100°C

For best results, substrate should be preheated (typically to 40°C for 20 seconds) to allow for fast capillary flow and facilitate leveling.

Technical Specifications

| General Properties | |

| Pot Life Pot Life Pot life is the amount of time it takes for the viscosity of a material to double (or quadruple for lower viscosity materials) in room temperature after a material is mixed. It is closely related to work life but it is not application dependent, less precise and more of a general indication of how fast a system is going to cure. | 168 hours |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.12 |

| Thermal Properties | |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 101 °C |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 2,600 mPa.s |