LOCTITE ABLESTIK 71-1

- High bond strength

- High purity

- Electrically conductive

Product Description

We regret to inform you that after the discontinuation of 71-X series in EU in March 2020 (by REACH/ECHA health and safety related handling restrictions per May 2020 in EU), there is now also a GLOBAL 71-X discontinuation due to a specific Raw Material discontinuation. Effective from the middle of September 2021.

Looking for a 71-1 alternative? Some close, but not drop in, solutions are LOCTITE ABLESTIK 8700E, LOCTITE ABLESTIK QMI529HT-LV, LOCTITE ABLESTIK 8064 and LOCTITE ABLESTIK 8068TB. There's also LOCTITE ABLESTIK 8700K for a Non Conductive option.

Check the alternative product table in the Additional information section and contact us for a quotation or for further advice.

LOCTITE ABLESTIK 71-1 die attach adhesive is designed for microelectronic and semiconductor packaging applications. It is formulated to provide high bond strength at ambient and elevated temperatures.

Technical Specifications

| General Properties | |||||||||||

| |||||||||||

| |||||||||||

| Physical Properties | |||||||||||

| Thixotropic index Thixotropic index Thixotropic Index is a ratio of a material s viscosity at two different speeds in Ambient temperature, generally different by a factor of ten. A thixotropic material s viscosity will decrease as agitation or pressure is increased. It indicates the capability of a material to hold its shape. Mayonnaise is a great example of this. It holds its shape very well, but when a shear stress is applied, the material easily spreads. It helps in choosing a material in accordance to the application, dispense method and viscosity of a material. | 2.9 | ||||||||||

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 14,000 mPa.s | ||||||||||

| Chemical Properties | |||||||||||

| |||||||||||

| Moisture absorption | 0.6 % | ||||||||||

| Mechanical Properties | |||||||||||

| |||||||||||

| |||||||||||

| Thermal Properties | |||||||||||

| |||||||||||

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 240 °C | ||||||||||

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 2 W/m.K | ||||||||||

Additional Information

These are close alternatives that we have found to work in the same applications that 71-1 used to work. Even though they have a range of different chemistries they have been tried from 71-1 users and some of them like 8600/8700, JM7000 have proven to be almost drop in solutions with some fluctuations in Thermal conductivity

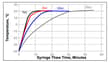

The peak temperatures for most of these products are very similar to 71-1 so most ovens should be able to handle them. Additionally there are single cure options that are easier to work with and process than the 71-1 Polyimide chemistry.

| Product Name | Viscosity (mPAs) | Thixotropic Index | CTE a1 (ppm/°C) | Tg(°C) | TC (W/mK) | Modulus @25°C (N/mm2) | Moisture absorption (%) | Ionics (Cl-, K+, Na+) | CVCM (%) | TML (%) | Cure (min + °C) |

| LOCTITE ABLESTIK 71-1 | 14,000 | 2.9 | 41 | 240 | 2 | 3,400 | 0.6 | 5/5/5 | 0 | 0.25 | 30 + 30 Ramp and Hold @150 + 175 |

| LOCTITE ABLESTIK JM7000 | 9,000 | - | 33 | 240 | 1.1 | - | - | 10/15/15 | 0.01 | 0.15 | 30 @150 |

| LOCTITE ABLESTIK 8600 | 7,500 | 4.7 | 46 | 187 | 3.9 | 9,600 | - | 10/10/10 | - | - | 30 + 15 Ramp and Hold @175 |

| LOCTITE ABLESTIK 8700E | 18,000 | 3 | 45 | 160 | 1.6 | 4,414 | 0.62 | 35/5/0 | 0 | 0.3 | 120 @121 |

| LOCTITE ABLESTIK QMI529HT-LV | 16,000 | 4 | 62 | 36 | 8 | 4,910 | - | 10/10/10 | 0.03 | 0.14 | 30 + 60 Ramp and Hold @175 |

| LOCTITE ABLESTIK 8064T | 12,000 | 5.8 | 47 | 44.5 | 22 | 5,260 | - | 10/10/10 | 0.05 | 0.25 | 60 + 60 Ramp and Hold @180 |

| LOCTITE ABLESTIK 8068TB | 11,500 | 5.5 | 25 | 25 | 100 | 12,500 | 0.21 | 20/0.5/1.5 | - | - | See TDS |

| LOCTITE ABLESTIK 8700K | - | - | 20 | 165 | - | - | 1.98 | 50/5/10 | 0 | 0.59 | 60 @175 |

| LOCTITE ABLESTIK 84-1LMISR4 | 8,000 | 5.6 | 40 | 120 | 2.5 | 3,900 | 0.6 | 20/10/10 | - | - | 60 @175 |

| LOCTITE ABLESTIK QMI519 | 9,000 | 4.2 | 40 | 75 | 3.8 | 5,300 | - | 20/20/20 | - | - | 15 @185 |

Some insight:

LOCTITE ABLESTIK 84-1LMISR4 is a product was born 30+ years ago (maybe more) by Ablestik and is still the top sales product of Henkel Electronics material by far. It provides an array of flexibilities from multiple Henkel factories, production frequencies to syringe sizes.

LOCTITE ABLESTIK QMI519 is also a volume runner, a little pricey but its robust Hybrid BMI/ Acrylate properties can enable upgraded performance device.

LOCTITE ABLESTIK JM7000 is a cyanate ester used almost exclusively for hermetic packaging so it can, in principle, work great as a replacement for 71-1.