LOCTITE ECCOBOND NCP5209

- Non conductive

- Excellent protection of electrical joints

- Small assembly gaps and tight pitches

Product Description

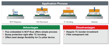

LOCTITE® ECCOBOND NCP 5209 is a non-conductive paste (NCP) underfill designed to facilitate next-generation fine-pitch copper pillar and copper OSP flip-chip devices. Overcoming the voiding and protection drawbacks of conventional capillary underfills, LOCTITE ECCOBOND NCP 5209 leverages thermal compression (TC) bonding to offer robust, complete bump protection of flip-chip devices, with bump pitches less than 100 µm and gaps less than 40 µm for a high-reliability result.

LOCTITE® ECCOBOND® NCP 5209 is a fast curing hybrid adhesive has improved fluxing and stability at 70°C up to 60 minutes and has been proven a high volume runner with long staging time (>60 min 70°C). With a Typical TCB cure within 2-4 seconds @ 240-280°C, High Tg of 180°C and low ionics (<5ppm) it achieves a longer stage life and better flowability than its direct rival, LOCTITE ECCOBOND FP 5201.

Its fast cure resin, improved solderability and good reliability make it ideal for high volume production and make it the #1 Non Conductive Paste Underfill of choice.

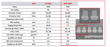

Technical Specifications

| General Properties | |||||||||

| |||||||||

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.5 | ||||||||

| Physical Properties | |||||||||

| Thixotropic index Thixotropic index Thixotropic Index is a ratio of a material s viscosity at two different speeds in Ambient temperature, generally different by a factor of ten. A thixotropic material s viscosity will decrease as agitation or pressure is increased. It indicates the capability of a material to hold its shape. Mayonnaise is a great example of this. It holds its shape very well, but when a shear stress is applied, the material easily spreads. It helps in choosing a material in accordance to the application, dispense method and viscosity of a material. | 2.2 | ||||||||

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 12,500 mPa.s | ||||||||

| Chemical Properties | |||||||||

| |||||||||

| Mechanical Properties | |||||||||

| |||||||||

| Thermal Properties | |||||||||

| |||||||||

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 145 °C | ||||||||