DMI-3006 Negative Type Solvent Developed Photosensitive Modified Polyimide Stress Buffer Coating

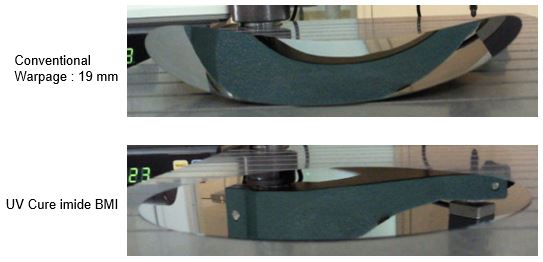

- No warpage of silicone wafer

- UV cured, no hard bake required

- Excellent dielectric properties

Product Description

DMI’s stress buffer coating is a negative type, solvent developed, photosensitive polyimide based precursor for stress buffer applications.

DMI’s photosensitive polyimide coating uses a modified polymide which outperforms industry standards because of its very low cure temperature and very low modulus. These two qualities ensure that there is minimum wafer warpage of the silicon wafer.

DMI’s photosensitive polyimide coating also guarantees excellent cured film properties such as great electrical performance because of its high dielectric strength and constant. The coating has a very low moisture absorption and high elongation giving it its high reliability.

DMI's photosensitive polyimide coating's main application is as a stress buffer or wafer buffer layer in wafer level packaging (WLP). The coating's low cure temperature and high dielectric strength ensure excellent performance as stress buffer in wafer level packaging. Other applications include post passivation layers for solder bumping or dielectric layer in wafer level packages.

Technical Specifications

| Chemical Properties | |||||||

| Moisture absorption | 0.1 % | ||||||

| Water Absorption | 0.1 % | ||||||

| Mechanical Properties | |||||||

| Elongation Elongation Elongation is the process of lengthening something. It is a percentage that measures the initial, unstressed, length compared to the length of the material right before it breaks. It is commonly referred to as Ultimate Elongation or Tensile Elongation at break. | 62 % | ||||||

| |||||||

| |||||||

| Thermal Properties | |||||||

| |||||||

| Decomposition Temperature | 446 °C | ||||||

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 54 °C | ||||||

Additional Information

We would like to pattern the DMI-3006. Do we need the R1247 developer or can we use a mixture of conventional solvents?

We can supply the material but we would prefer if you prepared your own supply for two reasons:

- You likely have these solvents in your inventory

- Shipping flammable solvents is very expensive

The R1247 is a simple mixture of 85 wt. % cyclopentanone (a common solvent used for developing) and 15 wt. % ethanol. We just add the two solvents to a container and shake to blend them together. We have found that pure cyclopentanone is a little too aggressive to the DMI-3006 so blending with ethanol reduces its nature.