Metal Repellency Treatment

- Renders metal surfaces hydrophobic/oleophobic

- 2-4 nm thickness

- Repellent to nearly any liquid

Product Description

Aculon's metal repellency technology renders any metal surface hydrophobic, oleophobic, and repellent to nearly any liquid. It is a nanoscale surface treatment that is easy to apply, optically clear, and ultra-thin (2-4nm). This treatment can be applied via several application methods, including dip and wipe, and no capital equipment is required.

Advantages of Aculon's Metal Repellency Treatment

- Repels water, oil, and organic material

- Long-lasting durable repellent performance

- Apply in minutes

- High chemical resistance

- Nontoxic, non-ozone depleting

Technical Specifications

| General Properties | |||||

| Color Color The color | Clear | ||||

| Solids | 5 % | ||||

| |||||

| Physical Properties | |||||

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 2 mPa.s | ||||

| Electrical Properties | |||||

| Visible Light Transmission | 100 % | ||||

| Thermal Properties | |||||

| Boiling Point Boiling Point The amount of degree’s needed to reach in order to make the substance boil. | 78 °C | ||||

| Flash Point Flash Point The flashpoint of a solvent is the lowest possible temperature at which it can vaporize to form an ignitable vapor. Flashpoint is often confused with “autoignition temperature”, which is the temperature at which a solvent ignites without an ignition source. | 13.9 °C | ||||

| Other Properties | |||||

| Coating Thickness | 2-4 nm | ||||

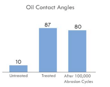

| Oil Contact Angle Oil Contact Angle The contact angle is the angle, conventionally measure trough the liquid, where a liquid-vapor interface meets a solid surface. | 80 ° | ||||

| Water Contact Angle | 116 ° | ||||

Additional Information

How to apply Metal Repellency Treatment

STEP 1 ⇨ CLEAN | STEP 2 ⇨ TREAT | STEP 3 ⇨ DRY |

|

| |

| Parts must be sufficiently clean before treatment for proper bonding and effective application. | Dip - Fully immerse the part in the treatment solution for 30 seconds. Withdraw the part at a steady rate to ensure even coverage. Allow to dry or cure depending on your substrate. Aculon Metal Repellency Treatment comes in 30 ml or 1L kits for dipping applications. | If curing is necessary (short dip times are used), the treated substrates are best cured at 120⁰C peak metal temperature for approximately 30 seconds. For silicon and titanium oxides, lengthening the cure time Aluminum does not need a cure if the dipping time is lengthened to 5 minutes/room temperature, otherwise, a cure is recommended. |

Wipe - Using a clean cloth apply the treatment by wiping it across the surface in a buffing motion for 1 minute per square foot. Aculon Metal Repellency Treatment comes in pre-moistened wipes, 30 ml or 1L kits for wiping applications. |

How to test for Hydrophobicity

To test for hydrophobicity, allow water droplets to fall onto the surface, which should bead up to a contact angle >90⁰. If the contact angle is <90⁰, then the surface is not

hydrophobic. The surface should be cleaned again and the Metal Repellency Treatment reapplied.

Application Ideas

| Impart repellency to stainless steel, pipes, and other industrial metals and materials |

| Non-fouling (ink-repellent) surface for printer nozzles | |

| Nonstick film for inside micro heat exchanger | |

Any application where added liquid repellency of metal surfaces is beneficial |