NanoClear Fluxophobic Stencil Treatment Wipes

- Best-in-class stencil treatment technology

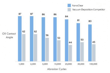

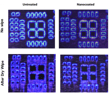

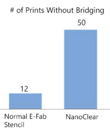

- Better quality printing

- Reduce underside cleaning

Product Description

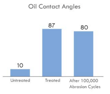

Aculon NanoClear® is the best-in-class stencil treatment technology that improves print quality, increases efficiency, lowers total costs and enhances printing with small apertures. By using NanoClear, your stencil will repel flux.

It is a cost-effective solution that is easily (no capital equipment) and quickly (<5 minutes) applied, which leads to a durable treatment that can reduce paste transfer, flux bleed, and solder ball transfer.

Advantages of Aculon's NanoClear®

- Reduce underside cleaning

- Treats sensitive apertures

- Treats aperture walls

- Increased print reliability

- Improve first-pass yield

Technical Specifications

Additional Information

How to Enhance NanoClear Durability

NanoClear is very chemical and abrasion-resistant, but coarse under-wipe papers designed for uncoated stencils can scratch the coating of the foil over an extended period of time.

• Softer papers are more effective at cleaning stencils and preserving the thin coating.

• Extending the frequency of under-wiping helps limit the abrasion, and is a benefit that NanoClear affords its users.

• Solvent wipe provides lubrication to decrease the abrasion of the wiper textile.

• Higher wiper pressures will increase the abrasion of the wiper textile.

• pH neutral, or pH9 will attack both wipe-on and spray-on coatings.

• Any signs of wear will first be visible at the end of the under-wipe stroke, where flux gets left behind on the stencil.