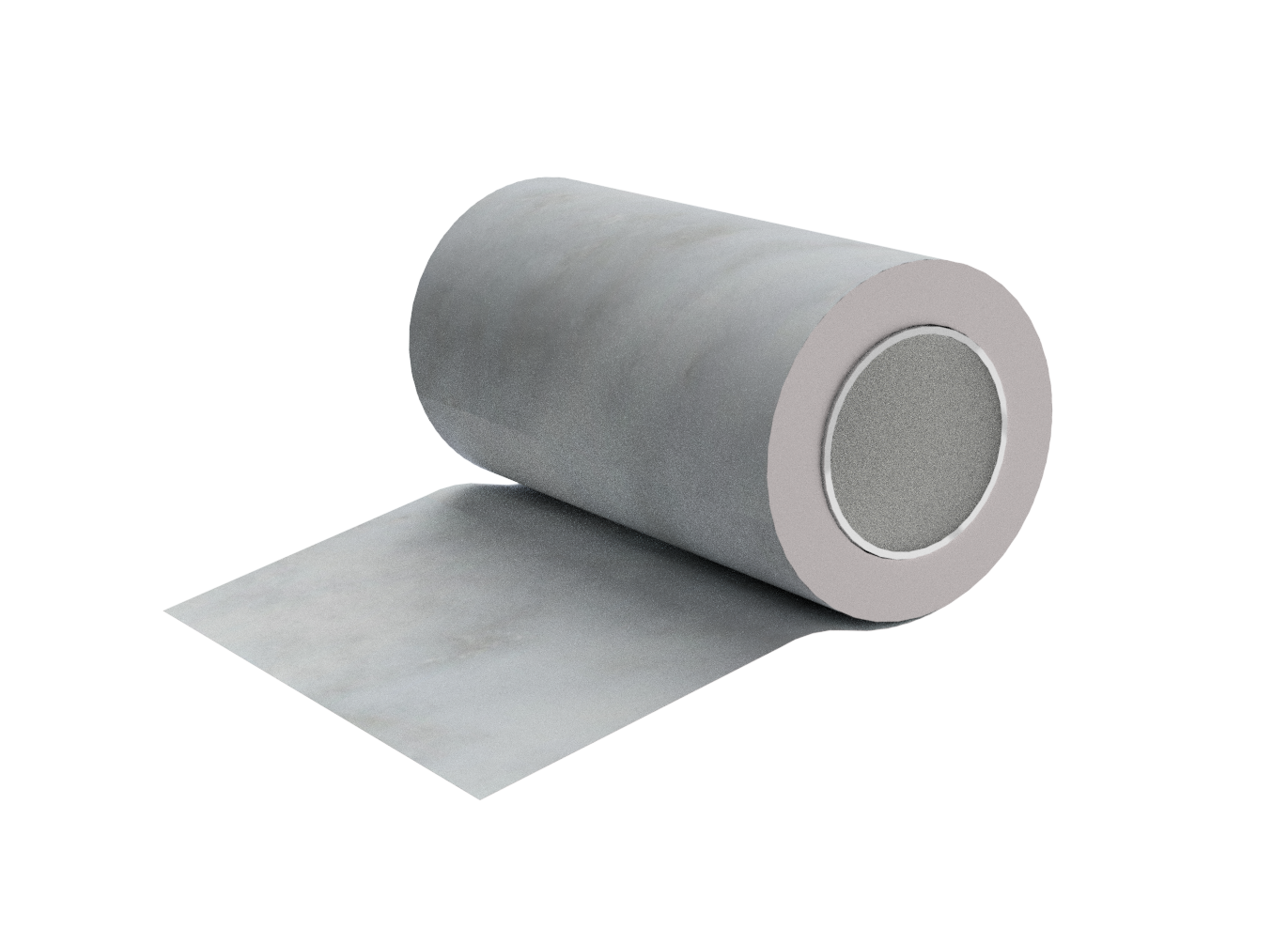

NKN 333 | 3-mil Nomex / 3-mil Polyimide / 3-mil Nomex Film

- 2 layers of nomex with 1 layer of polyimide

- 10 mil total thickness

- Thermal class H (180°-200°C)

Product Description

LINQTape NKN 333 is a three-ply laminate film consisting of 3 mils of Polyimide (Kapton) laminated between 3 mils of Aramid (Nomex) paper from each side, resulting in a film with a total of 9 mil (10 mil nominal) thickness. Nomex paper is bonded to the Polyimide film at high temperature and results in a laminate with good dielectric properties, high heat resistance and high mechanical strength.

NKN means Nomex - Kapton - Nomex. Both Nomex and Kapton are registered trademark names of Aramid paper and Polyimide film respectively. While the trademarks has expired a long time ago, the abbreviation for this kind of laminate remained NKN.

Nomex Kapton Nomex (Aramid Polyimide Aramid) films are great insulators for slot, phase, turn to turn, liner and barrier applications in rotating motors. They can be used as transformer and inductor windings while being a popular choice for a wide range of electrical applications.

Key Features:

- Good dielectric properties

- High heat resistance

- High mechanical strength

- Wide range of applications

Technical Specifications

| General Properties | |

| Film Thickness Film Thickness Film thickness is the thickness of a backing film without taking into account any coatings or adhesive layers. It is measured in micron and the conversion factor to mil is 0.039. | 228.6 µm |

| Release Liner Release Liner A paper or plastic-based film sheet used to prevent a sticky surface from prematurely adhering | None |

| Special Layer | Polyimide |

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 254 μm |

| Electrical Properties | |

| Breakdown Voltage Breakdown Voltage Breakdown voltage is the minimum voltage necessary to force an insulator to conduct some amount of electricity. It is the point at which a material ceases to be an insulator and becomes a resistor that conducts electricity at some proportion of the total current. After dielectric breakdown, the material may or may not behave as an insulator any more because of the molecular structure alteration. The current flow tend to create a localised puncture that totally alters the dielectric properties of the material. This electrical property is thickness dependent and is the maximum amount of voltage that a dielectric material can withstand before breaking down. The breakdown voltage is calculated by multiplying the dielectric strength of the material times the thickness of the film. | 18000 V |

| Mechanical Properties | |

| Elongation Elongation Elongation is the process of lengthening something. It is a percentage that measures the initial, unstressed, length compared to the length of the material right before it breaks. It is commonly referred to as Ultimate Elongation or Tensile Elongation at break. | 10 % |

| Tensile Strength (Thin Film) Tensile Strength (Thin Film) Tensile strength determines the resistance of a material to break under tension and it measures how much elongating load (or tensile stress) it can handle before fracture. To make it simple, it measures how much force we have to apply when pulling apart a material before it breaks. | 265 N/cm |

| Thermal Properties | |

| Temperature Resistance Temperature Resistance Temperature resistance is the maximum temperature that the material or product can withstand for a period of time. The temperatures listed should be considered as guidelines for an operating temperature of about 30 minutes. Typically, the material can withstand much longer times at temperatures about 20°C lower and can withstand much higher temperatures for short, intermittent times. | 200 ˚C |