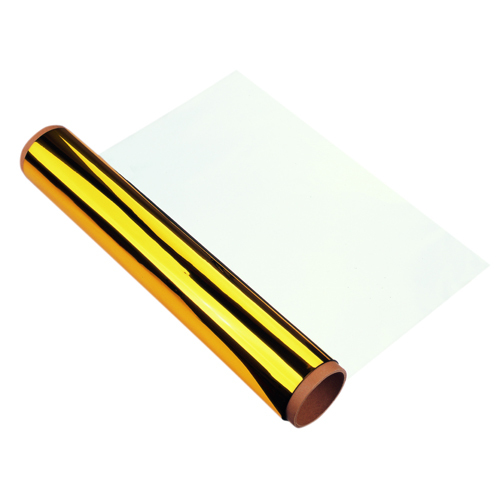

PIT1A-ALUM | 1mil Polyimide (Kapton) Film with Sputtered Aluminized Coating and Acrylic adhesive

- 1 mil polyimide film

- Sputtered Aluminized Coating

- >6000V breakdown voltage

Product Description

LINQTAPE PIT1A-ALUM is a high performance, high-temperature resistant aluminized polyimide film, formed by sputtering aluminum onto polyimide using an aluminum vacuum deposition method. This combination of materials allows that one side is an insulation side and the other is conductive. In addition to that we add an Acrylic adhesive either by coating it or laminating it on either side of the film (so Polyimide or Aluminum facing). The laminated version comes with a paper liner while the coated version comes without a liner.

LINQTAPE PIT1A-ALUM combines Polyimide and sputtered aluminum to give a very heat resistant, mechanically and chemically stable, radiation-resistant, and self-extinguishing product that has very high thermal conductivity and EMI shielding.

LINQTAPE PIT1A-ALUM is a used in a number of applications, including as a first surface mirror for multilayer insulation (MLI) blankets, EMI shielding, electromagnetic shielding tape and flexible etching wire. Please note that the Acrylic adhesive will (naturally) degrade in a much lower temperature than the Polyimide (±150°C). This layer is added to aid the application of the Film but you shouldn't expect it to last at the same temperatures without any degradation.

Technical Specifications

| General Properties | |

| Adhesive Layer Adhesive Layer A layer that is applied to one surface or both to bind items together and resist their separation | Acrylic |

| Adhesive Thickness Adhesive Thickness Adhesive thickness indicates the thickness of an adhesive layer. It refers to the adhesive thickness of a single side so for double sided tapes it always needs to be multiplied. | 38.1 µm |

| Chemistry Type | Polyimide |

| Color Color The color | Amber |

| Film Thickness Film Thickness Film thickness is the thickness of a backing film without taking into account any coatings or adhesive layers. It is measured in micron and the conversion factor to mil is 0.039. | 25.4 µm |

| Special Layer | Sputtered Aluminum Coating |

| Special Layer Thickness | 0.07 - 0.1 μm |

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 63.5 μm |

| Mechanical Properties | |

| Adhesion Strength Adhesion Strength Adhesion is the bond strength measurement of a coating to a substrate. When an adhesive is bonded to an item or surface, numerous physical, mechanical and chemical forces come into play, which may have an effect on each other. | 25 Oz/in |

| Elongation Elongation Elongation is the process of lengthening something. It is a percentage that measures the initial, unstressed, length compared to the length of the material right before it breaks. It is commonly referred to as Ultimate Elongation or Tensile Elongation at break. | 40 % |

| Electrical Properties | |

| Breakdown Voltage Breakdown Voltage Breakdown voltage is the minimum voltage necessary to force an insulator to conduct some amount of electricity. It is the point at which a material ceases to be an insulator and becomes a resistor that conducts electricity at some proportion of the total current. After dielectric breakdown, the material may or may not behave as an insulator any more because of the molecular structure alteration. The current flow tend to create a localised puncture that totally alters the dielectric properties of the material. This electrical property is thickness dependent and is the maximum amount of voltage that a dielectric material can withstand before breaking down. The breakdown voltage is calculated by multiplying the dielectric strength of the material times the thickness of the film. | 6000 V |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.0x1015 Ohms⋅cm |

| Thermal Properties | |

| Temperature Resistance Temperature Resistance Temperature resistance is the maximum temperature that the material or product can withstand for a period of time. The temperatures listed should be considered as guidelines for an operating temperature of about 30 minutes. Typically, the material can withstand much longer times at temperatures about 20°C lower and can withstand much higher temperatures for short, intermittent times. | 400 ˚C |

| Other Properties | |

| RoHS Compliant RoHS Compliant RoHS is a product level compliance based on a European Union Directive which restricts the Use of certain Hazardous Substances in Electrical and Electronic Equipment (RoHS). Products compliant with this directive do not exceed the allowable amounts of the following restricted materials: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), with some limited exemptions | Yes |