IR Sensors

The IR (infrared) sensor is one type of photoelectric sensor, used to detect specific characteristics in its surroundings through emitting or detecting IR radiation. These sensors can also be used to detect or measure the heat of a target and its motion. In many electronic devices, the IR sensor circuit is a very essential module. This kind of sensor is similar to human’s visionary senses to detect obstacles.

IR Sensor Working Principle&Types

An infrared sensor includes two parts namely the emitter & the receiver (transmitter or detector), so this is jointly called an optocoupler or a photo-coupler. Here, IR LED is used as an emitter whereas the IR photodiode is used as a receiver. The photodiode used in this is very sensitive to the infrared light generated through an infrared LED. The resistance of photodiode & output voltage can be changed in proportion to the infrared light obtained. This is the fundamental IR sensor working principle.

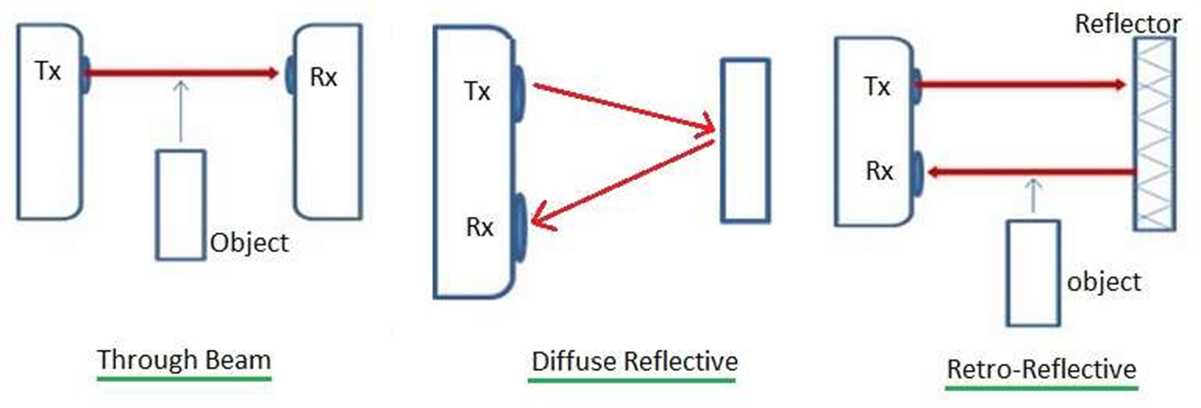

The type of incident that occurred is the direct otherwise indirect type where indirect type, the arrangement of an infrared LED can be done ahead of a photodiode without obstacle. In indirect type, both the diodes are arranged side by side through a solid object ahead of the sensor. The generated light from the infrared LED strikes the solid surface & returns back toward the photodiode.

IR Sensors in Automotive Applications

Nowadays, automotive industry is heading to the challenges like smarter, safer and greener. Optical semiconductors such as sensors and LEDs help providing light information about exterior and interior light brightness, driving environment signals and drivers‘ command, which could largely improve the driving comfort experience and smartly help driver complete distracted tasks. Among those sensors, IR sensors has a broad applications in cars nowadays.

Why the IR sensor are specifically popular in cars? IR sensor could work in days and nights without visible illumination thus less likely to get disturbed by ambient light. It is used as autonomous driving, gesture recognition, driver monitoring, climate sensor, etc. As automotive applications, IR sensors being applied may meet automotive standard stress test qualification AEC-Q100. Common stress tests are like:

- Temperature cycles: -50°C~150°C, for 1000 cycles

- Temperature and humidity bias: 1000hrs @85°C and 85%RH,

- High temperature storage: 1000 hrs @150°C

- Autoclave: 96 hrs @121°C and 100%RH

- Preconditioning to simulate solder reflow: 3 x 260°C, MSL 3 conditions

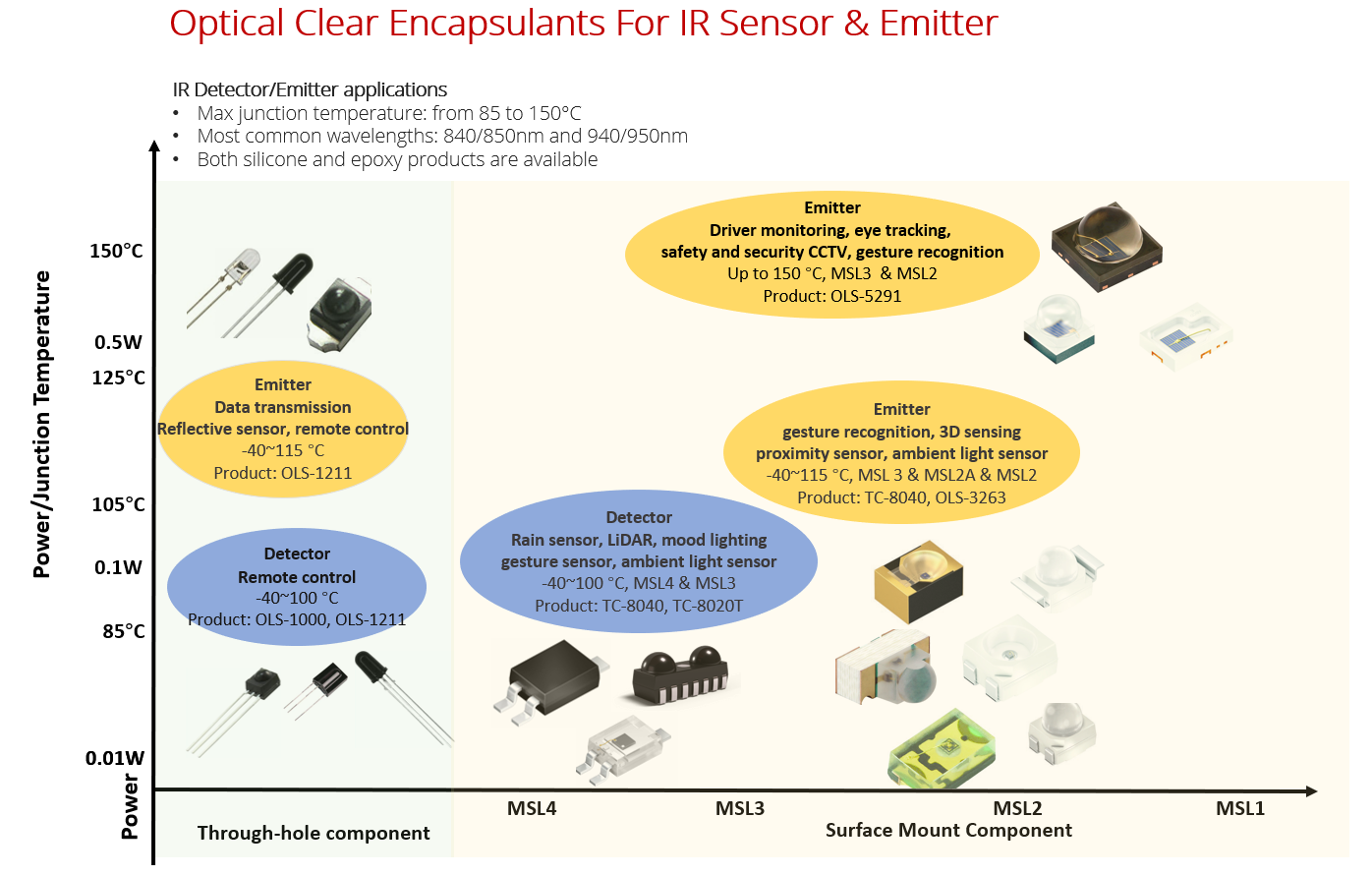

But it always depends on IR sensors' function in cars and device package type. We could classify them by power and MSL level.

Optically Clear Materials For IR Sensor

For IR sensors application, Caplinq provide OLS series of liquid encapsulants and TC series of molding compounds as encapsulating solutions.

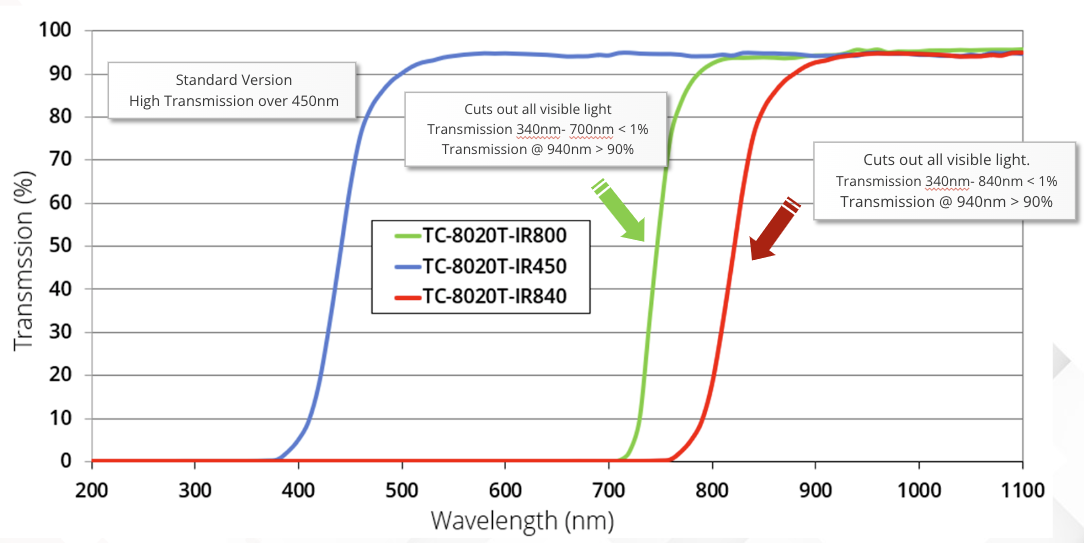

1. Clear Molding Compound TC-8020

TC-8020T is a single component epoxy with superior adhesion performance, transmittance and stability at high temperatures. It is mainly utilised to package single color (monochrome) LEDs, 7-segment LED displays, compact LED indicators, monochrome ChipLEDs and photo-links.It offers good adhesion to Bismaleimide Triazine - BT substrates and metal leadframes, good flexural modulus, and excellent anti-reflow performance while also passing the stringent MSL 3/2A JEDEC requirements.

PROPERTY | Units | XX-330HQ | TC-8020T |

Viscosity | Pa.s | 400 | 300 |

Spiral Flow @ 150°C | inches | 45 | 40 |

Hot Plate Gel Time @ 150°C | sec | 29 | 40 |

Glass Transition Temperature | °C | 125 | 125 |

CTE by TMA, Alpha1 CTE by TMA, Alpha2 | ppm/°C | 71 | 70 170 |

Moisture absorption PCT |

wt% | - | 0.17 |

2atm*100%RH*24hr@121°C | wt% | 2.9 | 3.2 |

Flexural Strength @25°C Flexural Modulus @25°C | MPa MPa | 130 | 135 3050 |

200°C * 4 hr, yellowing ∆b | - | 25 | 5 |

280°C * 30 min, yellowing ∆b | 49 | 33 | |

UV * 4 hr, yellowing ∆b | 26.5 | 11 | |

Transmittance @450nm,1mm | % | >90 | |

Refractive Index @633nm | - | 1.52 | 1.56 |

Comment | STD Item | STD Item for through-hole and surface mount component MSL3 |

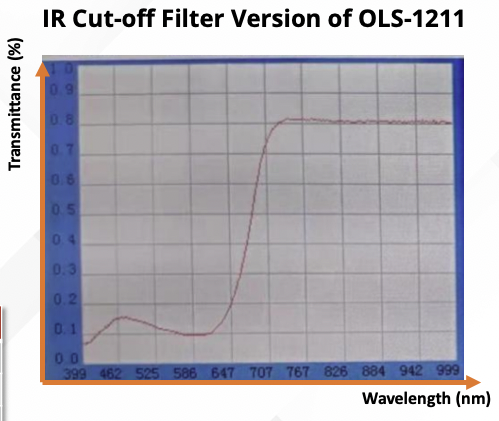

2. Two-part Epoxy Liquid Encapsulant OLS-1211

Features & Benefits:

- Tg - 130°C

- Transmittance >90%@400nm

- Low transmittance decay and anti-aging

- Good adhesion to leadframe

- Good performance in thermal shock tests

Target Applications:

- Sensor applications, for both Emitter and receiver

- IR sensors with unique light-filtering technology

| Reliability Test conditions | Results |

| Reflow Stability, 5 x 30 sec @260 °C, IR Reflow | Pass |

| Red Dye Penetration, water boiling 100 °C*2hrs | Pass |

| Thermal Shock, -40 °C~105 °C*500 cycles | Pass |

| Lighting Decay, 100mA*1000H | Decay less than 7% |