TGP 5000 | Thermal Gap Pad

- 0.3 Thermal Impedance

- 5.0 Thermal Conductivity

- Good elastic modulus

Product Description

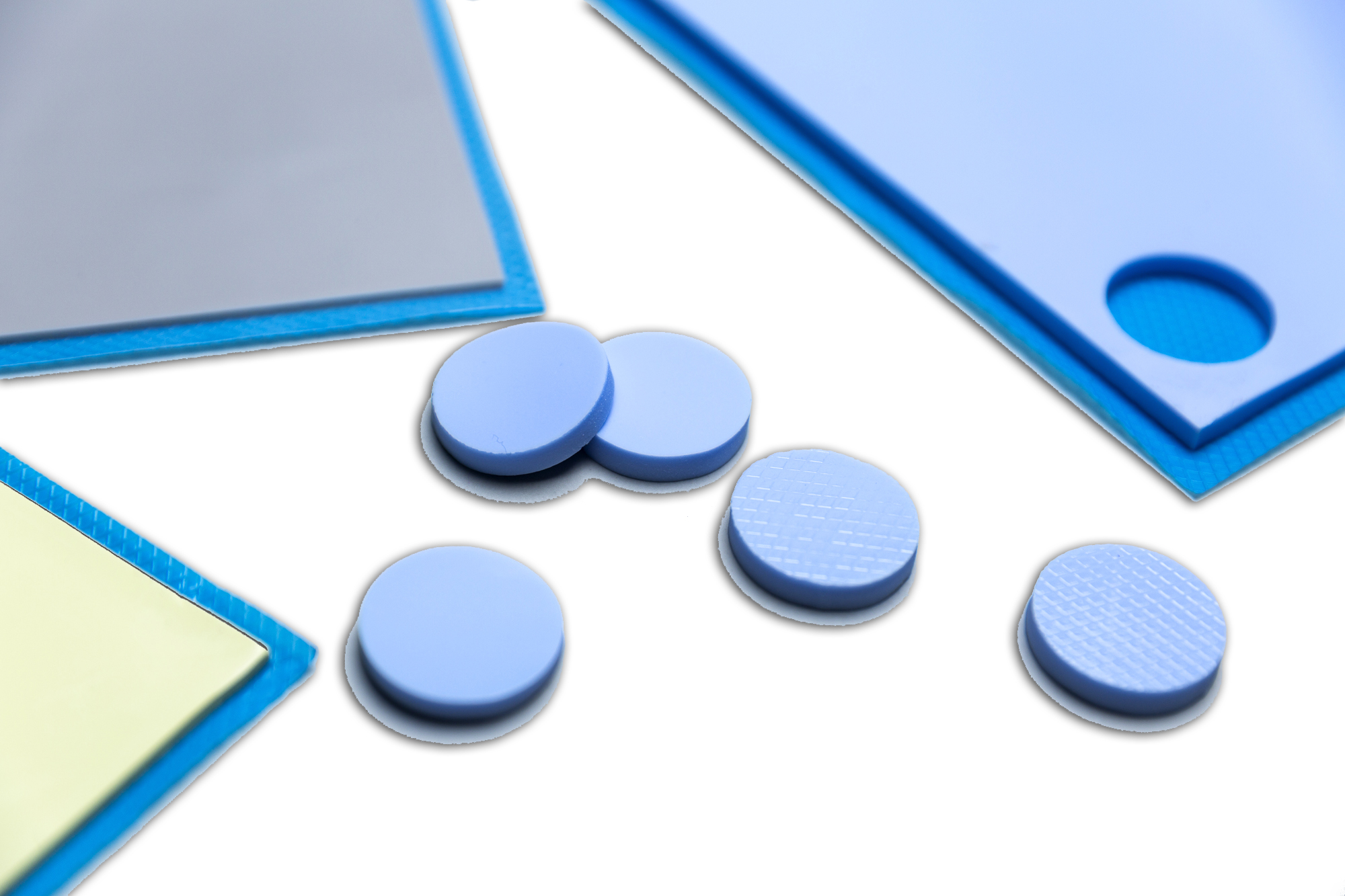

Honeywell's TGP5000 Thermal Gap Pads (TGP) stand right in the middle of our Thermal gap pad portfolio. The ratio of performance and cost is tightly balanced and the product's properties provide high thermal performance with ease of use across a multitude of applications. Their ultra-high compressibility enables low stress and excellent conformity to mating surfaces. They are designed to minimize thermal resistance at interfaces, and maintain excellent performance through reliability testing.

Honeywell's TGP5000 is naturally tacky, with a very good elastic modulus, and requires no additional adhesive which could inhibit thermal performance. Products have very low hardness and are available in a thickness range from 0.5mm to 5.0mm.

Technical Specifications

| General Properties | |||||

| Color Color The color | Blue | ||||

| Film Thickness | 0.5 - 5 mm | ||||

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 3.3 | ||||

| Electrical Properties | |||||

| |||||

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 8.0x1013 Ohms⋅cm | ||||

| Mechanical Properties | |||||

| |||||

| Thermal Properties | |||||

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 5.0 W/m.K | ||||

| Thermal Impedance | 0.3 °C·cm²/W | ||||

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V-0 | ||||

Additional Information

Are there thermal interface materials that also have EMI shielding?

It is very challenging to formulate a high TC, 5 W/m.K TIM, which also performs well as an EMI shielding ( or absorber).

Thermal Conductivity and EMI are achieved by fillers inside the formulation. Fillers that provide good EMI lead to low thermal conductivity and vice versa. So it is not easy to satisfy both as a 2 in 1 solution.

To add to that, EMI performance is directly related to the frequency of the application. For example, it is easier to achieve good EMI shielding at high-frequency applications, like base stations in telecom, while it is difficult to achieve it at 2.5G Hz to 4 G Hz, which is at a lower frequency. All these need to be taken into account before we can properly answer this question.

Thickness range:

- 0.5-5.0mm with 0.25mm incremental

Thickness Tolerance: >1mm, ±10%

- 0.5-1mm, ±0.1mm

- <0.5mm, ±0.05mm